Universal Robots Handpicks Systems Integrators to Deploy ActiNav Next-Generation Machine Loading

April 28, 2021

Today, solutions for unstructured picking and placing of parts into machines are solely focused on the vision aspect, often requiring additional programming to bridge the gap from “pick” to “place” – especially if the “place” is not just dropping into a box but accurately inserting parts into fixtures for further processing.

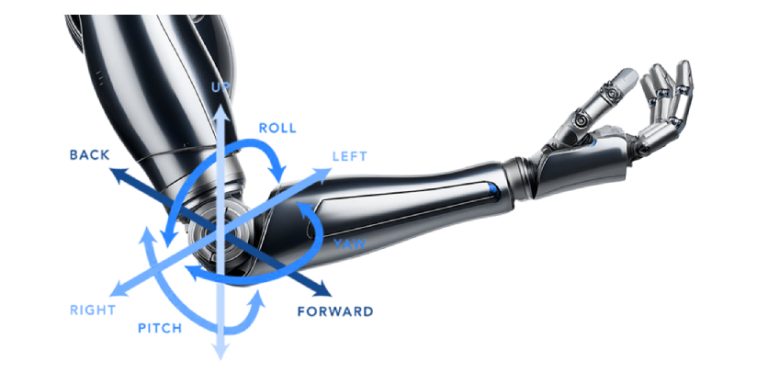

ActiNav changes all that, combining real-time autonomous motion control, Universal Robots cobots, vision and sensor systems in one seamless Application Kit that solves the random bin picking challenge in machine tending applications. To help manufacturers integrate ActiNav into machining cells, UR has vetted and selected a limited group of systems integrators across the U.S. to deploy the next-generation machine loading solution.

The select systems integrators are:

Eckhart Inc. (Michigan), Integro Technologies Corp. (North Carolina), Southwestern Production Technology Solutions (Texas), and Cross Company (North Carolina). Additional integrators in the U.S. and Canada are expected to be approved as ActiNav Solution Providers before the end of Q2, 2021.

“Our selection process focused on integrators with expertise in both vision and robotics, delivering superior value, and on time/on budget projects for customers,” says Bryan Bird, Regional Sales Director for Universal Robots’ North America division.

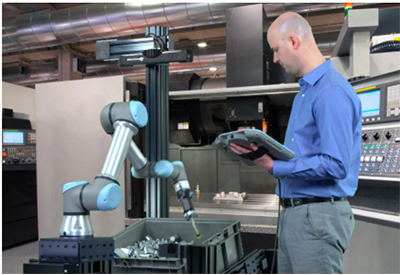

The selected systems integrators have all been provisioned with in-house demo units, enabling them to quickly develop proofs of concepts for customers in their region. “Integrating ActiNav into a machining cell is where the expertise of the right systems integrator really shines,” says Bird. “Our integrators will be able to quickly handle all peripheral requirements such as integration with safety sensors, machine interfaces, end-of-arm tooling and other components that all need to work together.”

Eckhart Inc. was the first company to become an ActiNav Solutions Provider. “We look forward to delivering increased machine uptime, quality and efficiency to manufacturers in our region,” says Sheldon Coney, director of robotics at Eckhart Inc. “In many ways, ActiNav will set a new level of operational expectations regarding the future of intelligent systems.”

Launched in April 2020, ActiNav has been deployed with numerous manufacturers across North America, who were seeking a simple solution to a complex problem. One of them is Flywheel Supply in Iowa. “The only way that made sense for us to put a robot on a machine tending application was to be able to do randomized bin picking,” explains Zach Northway, co-owner and lead project engineer at Flywheel Supply. “The cycle times on the machine are so short that if an operator has to stand there and line parts up in an organized fashion for a robot to pick them in a traditional sense, it would defeat the entire purpose of using the robot to begin with, because your operator is still standing there.”

In Flywheel’s ActiNav application, the UR5 cobot picks parts from a deep bin and places them in the jaws of a machine that indexes to multiple stations to perform tasks such as drilling, chamfering, and internal and external threading. Ultimately, the ActiNav system will process as many as 1,500 different part numbers, so it must be quickly programmable to pick parts of different shapes, sizes, and weights. “The biggest advantage to ActiNav is that it can take randomization of parts being dumped in a bin, and as the bin gets low, a person can just come by and dump some more into the bin and it will keep picking parts,” says Northway. “It doesn’t have to be reset, recalibrated—anything. It notices the bin amount changed and it keeps on going.”

For more information, visit www.universal-robots.com.