Textile Expert TSG Increases Productivity With the Help of ABB’s High-Performance Web Tension Load Cell Technology

February 1, 2025

The complex nature of textile manufacturing, encompassing spinning, weaving, finishing, and dyeing processes, demands sophisticated technological solutions to meet both production and quality requirements. Italy’s Tintoria Stamperia Gorlese (TSG) has increased productivity and reduced installation and tuning time by up to 50% by upgrading its machinery with advanced web tension load cells.

The textile industry is rapidly transforming, driven by technological advancements, sustainability efforts, and the need for consistent quality. Globally, manufacturers are replacing older techniques and outdated equipment with innovative solutions and automation.

Delivering flawless fabrics for more than 35 years

Located 30 kilometres northwest of Milan, TSG specialises in dyeing, finishing, and printing synthetic fabrics for clothing, furniture, and other industries. Founded in 1987, TSG operates a 10,000 square metre production facility with a focus on energy efficiency and sustainability. The company recently installed a photovoltaic system that powers the facility with approximately 200 KWP.

The need to modernise web tension measurement

TSG uses five atmospheric jigger machines for the pre-treatment, bleaching, and wide-width dyeing of fabrics, alongside two under-pressure jiggers for high-temperature dyeing. Jiggers are rotating drum machines that hold the fabric to be dyed, with atmospheric jiggers operating under normal pressure and under-pressure jiggers used for high-temperature dyeing.

In this process, accurate web tension measurement is essential for ensuring fabric quality and reducing web breaks, which increases productivity. Historically, dancer rolls were used for tension measurement, but high-performance web tension load cells have become the preferred solution due to their precision and reliability.

Facing maintenance problems with their previous tension measurement solution, TSG sought a more advanced option to gain process insights, improve efficiency, ensure consistent quality, and reduce maintenance costs. Unlike traditional methods, web tension load cell technology enables continuous, real-time tension monitoring and measures the actual web tension directly rather than relying on the movement of a roll.

ABB’s Pressductor® Radial Tensiometer Load Cells for accurate web tension measurement

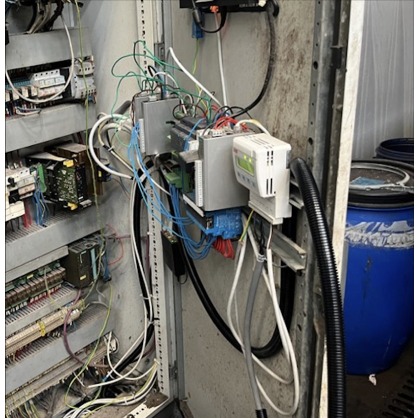

TSG adopted ABB’s Pressductor® Radial Tensiometer Load Cells, which deliver stable, reliable web tension measurement under harsh environmental conditions, such as those in dyeing processes. The PRT load cells are designed to provide precise measurements for jiggers and other textile machinery.

The Pressductor® technology generates measurement signals based on changes in magnetic fields when exposed to mechanical force. This approach, which does not rely on physical movement or deformation, ensures high sensitivity, exceptional overload tolerance, and long-term reliability.

In contrast, traditional systems depend on physical movement, such as bending or stretching elements, to generate signals, making them more susceptible to challenging operating conditions.

A step change in reliability and productivity

The introduction of ABB’s PRT load cells at TSG reduced operator intervention, simplified adjustment and maintenance, and increased the safety and efficiency of the textile line. The solution also significantly enhanced productivity and reduced installation and tuning time by up to 50%.

Martino Turconi, TSG General Manager, stated: “With ABB’s load cells, we have seen much better results in terms of both production quality and production efficiency. The system is easy to program and easy to operate.”

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps customers in process, hybrid and maritime industries improve performance and safety of operations, enabling a more sustainable and resource-efficient future. go.abb/processautomation

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on over 140 years of excellence, ABB’s more than 105,000 employees are committed to driving innovations that accelerate industrial transformation. www.abb.com

More Information

For more information please contact:

Media Relations

Olga Apostolova

Phone: +47 468 18 096

Email: olga.apostolova@no.abb.com

ABB Ltd

Affolternstrasse 44

8050 Zurich

Switzerland