Survey Insights: How Manufacturers are Embracing Technology in 2024

August 1, 2024

Why do manufacturers invest in technologies like robotics, cloud computing and AI? What’s the main barriers to them adopting new tech? And how do they plan to invest in the future?

This Spring, Universal Robots conducted a comprehensive survey involving 1,200 manufacturers across Europe and North America to understand their views on new technologies and learn how they plan to invest on both short and longer term. Here’s what they told them.

1. AI is a technology of the present, not just the future

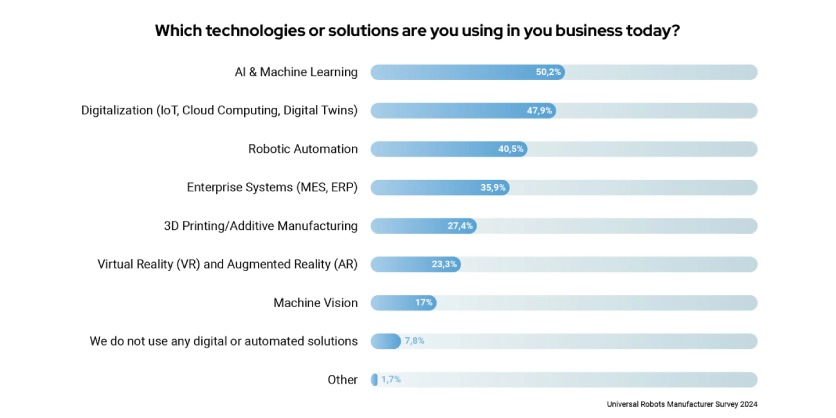

The AI hype has been omnipresent the past 18 months since ChatGPT launched and artificial intelligence became the talk of the town – all over the world. But the rise of AI technology is much more than just hype. Our survey indicates that more than 50% of manufacturers are already incorporating AI and machine learning into their production processes today. This means AI and machine learning are recognized as critical technologies for current operations and future investments and AI-powered robotic solutions will become more prevalent across industries. The second prioritized investment area for manufacturers is digitalization, followed by robotic automation.

2. Productivity and quality are top drivers for investing in new technologies

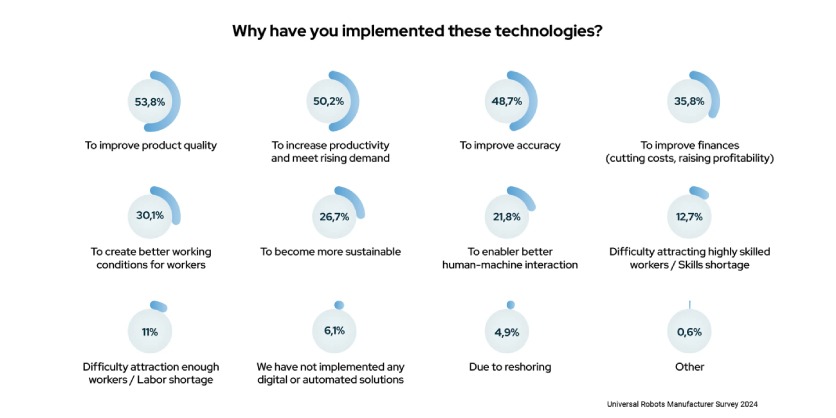

The top three metrics driving current technology adoption among manufacturers all focus on enhancing product and output. A significant 54% of manufacturers prioritize improving product quality, recognizing that better quality can lead to increased customer satisfaction and fewer returns or defects.

Close behind, 50% of manufacturers invest in technology to increase productivity and meet rising demand, aiming to streamline operations and boost efficiency. Finally, 49% of manufacturers are motivated by the desire to improve accuracy, reducing errors and ensuring precision in their production processes. These metrics highlight the industry’s commitment to leveraging technology to achieve superior performance and competitiveness in the market.

3. Manufacturers prioritize ease of use and reliability

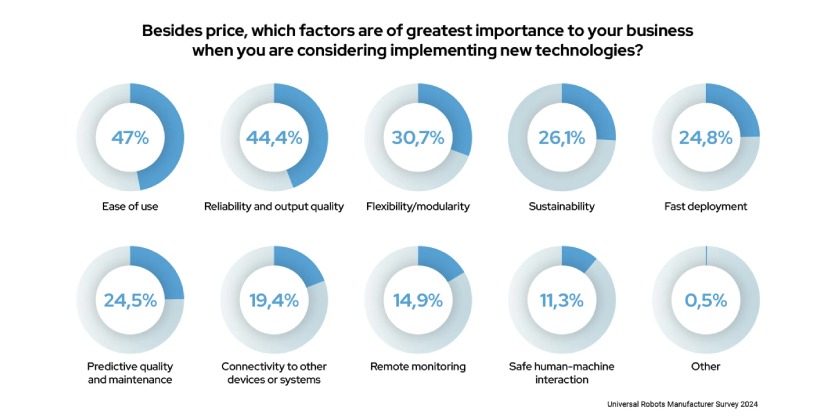

As automation and AI gain traction across sectors, manufacturers prioritize ease of use as the key factor when investing in new technologies, with 47% saying that its of greatest importance to them that technologies are straightforward to integrate and operate. This is closely followed by reliability. In other words: it needs to be easy, and it just needs to work.

Other important factors for manufacturers include flexibility and modularity, sustainability, fast deployment and predictive maintenance.

The latter is linked to AI, making it logical for manufacturers to focus on multiple factors and technologies that can work together when investing.’

4. ROI tops the list of concerns

With so much to be gained from automation, what are the factors holding manufacturers back from investing in new technology?

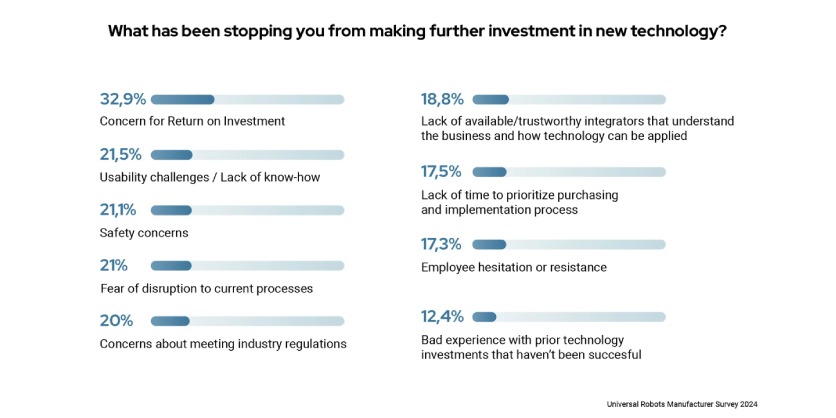

Our survey found that Return on investment (ROI) stands as the top concern, with manufacturers prioritizing investments that promise maximum value. Here fast integration, reliability, ease of use, precision and flexibility are all important factors as businesses are of course looking for the most cost-effective solutions.

Other factors include concerns about usability challenges and lack of in-house expertise. Concerns about safety and potential disruptions to current processes are also hindering investment.

Lastly, some manufacturers have been put off by unsuccessful previous investments or are concerned their employees will resist the adoption of new technologies, making them hesitant to venture into new territory.

5. Manufacturers look to AI, Robotics, and Digitalization to propel future growth

Looking ahead to both the near and far future, manufacturers believe that AI and machine learning (56%), robotic automation (43%), and digitalization (IoT, cloud computing, digital twins) (41%) hold the most potential to fuel their growth, making them key considerations for investments over the next decade.

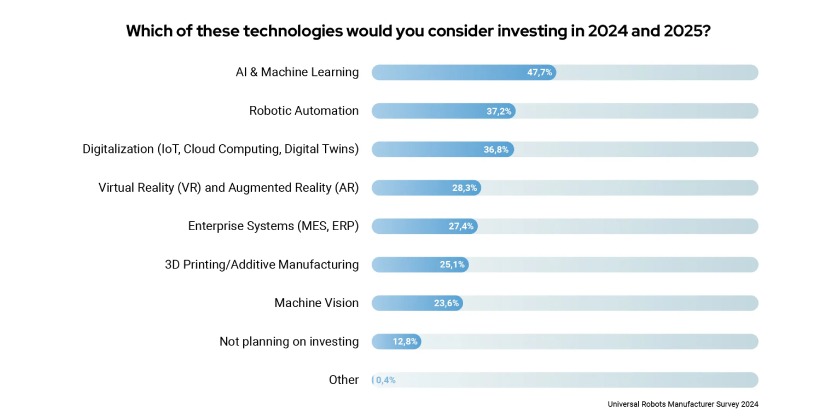

Currently, 48% of manufacturers report that they are already considering investing in AI and Machine Learning already this year or the next. Additionally, 37% are looking into investing in robotic automation, and another 37% are focusing on digitization.

This shows that businesses are increasingly adopting and planning to invest in these advanced technologies to enhance product quality, boost productivity, and sustain long-term growth. The focus on AI and machine learning aims to optimize processes and decision-making, while robotic automation promises to streamline operations and increase efficiency, quality and productivity. Meanwhile, digitalization efforts are set to revolutionize data management and connectivity, paving the way for more integrated and agile manufacturing environments.

These technologies will also continue to become even greater connected, as both physical AI capabilities and the demand for cloud-connected robotics and IT/OT connections are developing rapidly.

6. Do businesses tend to overrate their tech advancement?

It’s often difficult to know how you measure up to competition in terms of technological capabilities, and this survey shows that a significant majority (78%) rate their technological advancement as intermediate or advanced, with 40% considering themselves in the top 25%. Similarly, only 10% see themselves as part of the bottom 25%.

12% of manufacturers view themselves as technology trailblazers (top 10%).

The question then is: Do businesses overrate their tech advancement? And if so, what does this mean for how they will approach emerging technologies in the coming years? Will they rest on their laurels, or does this self-assessment indicate a high level of tech-confidence that will prompt these manufacturers to continue investing in new technologies to further develop their business?

Time will tell, and while the data from this survey can’t provide a definitive answer, it certainly shows that AI, digitization and automation are well on their way to become cornerstone technologies in all manufacturing industries.

About the survey

The purpose of this survey, which data was data was collected in March 2024, was to uncover how manufacturers across Europe and North America utilize technology today. It provides insights into the motivations for adopting new technologies, how manufacturers perceive their performance relative to other companies, and their future technology investment plans and expectations.

With a confidence rate of 99%, the survey gathered responses from 1,195 participants, including 358 decision-makers from seven different countries. The participants represented 569 large enterprises and 278 small and medium-sized companies. They come from various industries, primarily manufacturing, healthcare, food and beverage, and automotive.

About Universal Robots

Universal Robots believes that collaborative robotic technology can be used to benefit all aspects of task-based businesses – no matter what their size.

They believe that the latest collaborative robot technology should be available to all businesses. The nominal investment cost is quickly recovered as their robotic arms have an average payback period of just six months.

Related Story

Universal Robots and MiR Open New Robotics Hub in Denmark

Universal Robots, the Danish collaborative robot (cobot) company, and MiR, the Danish manufacturer of AMRs (autonomous mobile robots), recently celebrated the Grand Opening of their new 215,000 sq. ft. headquarters in Odense, Denmark. Partners from UR and MiR’s global ecosystems attended the event, including NVIDIA and Siemens, with whom Teradyne Robotics and its companies have recently announced several collaborations.