PC-Based Control and Drive Technology in Robotics

Premium finish with professional finesse

September 17, 2024

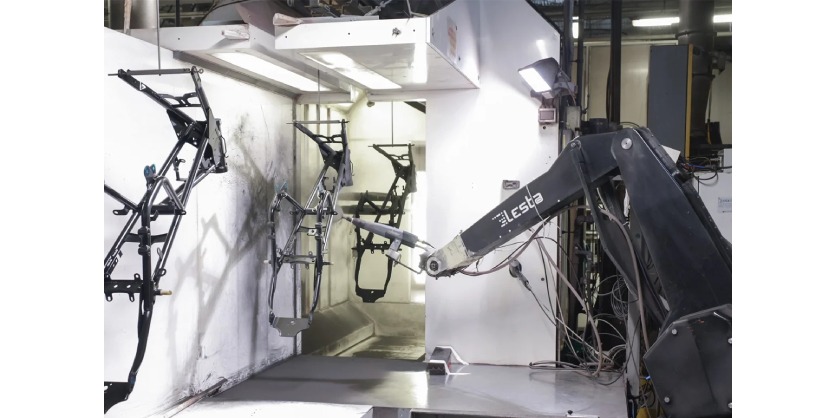

A perfect surface finish is the most obvious sign of a high-quality component. Achieving this consistently throughout series production is a challenge many manufacturers face, and this prompted Lesta srl, an Italian company, to develop its innovative painting robots. Flexibly automated with PC-based control from Beckhoff, these robots are suitable for use in a wide range of painting tasks, making a crucial contribution to optimizing the surface-finishing process.

Founded in 2010 in Dairago near Milan, Lesta, a robot manufacturer, specializes in industrial robot-based painting systems. Around 700 Lesta robots are currently in operation, with the company’s head of automation, Fabio Ferrario, noting that, “Around 100 systems are added each year across a wide range of industries.” The spectrum ranges from metal, wood, plastic, glass, and ceramics producers through to applications in the textile and food industries. To cater to the different target markets, the robots are available in several variants, including with ATEX and UL Hazardous Location approvals.

Lesta has also developed auto-learning, anthropomorphic robots, such as the Lebot MV A5 and MV A6. These models are capable of recording the previously manually taught movements of all axes in real time and then accurately reproducing them in automatic mode. The painter moves the robot arm with the motors switched off thanks to a pneumatic compensation system that is virtually resistance-free and weightless.

As the pneumatic weight compensation remains active during operation, the motors only have to exert minimal force. This reduces the required motor power, its size, and the masses being moved, which in turn benefits the overall dynamics.

PC-based control makes a difference

For Fabio Ferrario, the company’s continued strong growth clearly demonstrates the acceptance of the robots: “We have always had a widely recognized excellent reputation in the mechanical sector, but what truly sets us apart is the exceptional performance of our PC-based control systems.” When it comes to the development of the automation and control application, Lesta relies on TwinCAT 3. TwinCAT 3 is flexible and open and this, along with the broad product range from Beckhoff, has proven to offer crucial advantages.

One such advantage is the way Lesta is able to build on the TwinCAT libraries and combine them with its own expertise, which includes specific coordination of the interpolated movement of the robot axes. “TwinCAT 3 allows us to build an effective high-performance system based on Beckhoff products, which we can expand at any time with third-party components or additional algorithms if required,” states Fabio Ferrario.

Flowing movement like a real painter

Depending on the application, Lesta robots feature between five and over a dozen interpolating axes. Fabio Ferrario explains, “The challenge lies in getting the robots to replicate the smooth, fluid movement of a painter perfectly.” However, achieving a uniform surface coating on workpieces requires more than just precise positioning. This is why engineers and technicians at Lesta use TwinCAT 3 PLC/NC PTP (TC1250) and TwinCAT NC Camming (TF5050) to optimally replicate the movements of a painter.

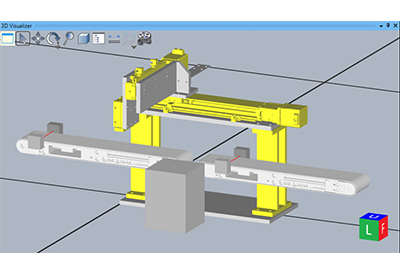

Manual teaching of the anthropomorphic robots is also integrated into TwinCAT, while the safety functions are implemented via TwinSAFE. Lesta exclusively uses the .Net framework from Microsoft for visualization purposes. The HMI application runs in parallel with the control task on the same computer – a CX5140 Embedded PC with an Intel Atom® quad-core processor. The visualization and control application are linked via the ADS protocol, and a CP2915 multi-touch built-in Control Panel is used as the HMI hardware.

When it comes to implementing the motion sequences generated in TwinCAT, Lesta relies on the AX8000 multi-axis servo system, as this can implement sophisticated motion profiles with high dynamics while maintaining a smooth, precise performance. Fabio Ferrario sees further advantages in the compact dimensions and in One Cable Technology (OCT) for connecting the AM8032 and AM8043 servomotors. These not only save space in the control cabinet, but also reduce material costs and installation time. “We typically only need to spend a week at the customer’s site, which covers everything from the installation to commissioning of the painting station,” explains Ferrario. “By Friday, the customer is already set up and ready to go.”

Scalability as a competitive advantage

It makes no difference whether a project involves a 6-axis robot or a 12-axis gantry crane variant, a powder or wet coating system: all variants are based on a master configuration with functions activated according to the robot type. This flexibility is attributed to the open and easily scalable platform from Beckhoff. As Fabio Ferrario highlights, “There is no doubt that the scalability of our systems is a key USP that sets us apart from our competitors.”

The painting systems are often integrated into the customer’s network to exchange data with other system components or factory management systems. What’s more, the availability of the OPC UA communication standard in TwinCAT assures the necessary connectivity and makes the Lesta machines Industry 4.0-ready.

Looking ahead to future developments, machine learning is a hotly debated topic. Lesta anticipates that this technology will lead to further increases in productivity and quality, such as the automatic generation of painting strategies and routes. Here too, Fabio Ferrario relies on the Beckhoff automation and control platform, which can simply be updated as required on account of its openness and scalability. After all, machine learning and deep learning are already available as TwinCAT functions.

Further information

Related Story

PC-Based Control Technology in the Semiconductor Production for Photovoltaic Equipment

For growing monocrystalline semiconductors, the Chinese company Jingsheng Mechanical & Electrical originally used a separate process and temperature control system. Since the changeover to PC-based control technology from Beckhoff, it not only helps to save costs, but also facilitates the implementation with its scalability. As added value for the customer, the TwinCAT software enables the protection of intellectual property.