Outdoor Enclosures – The Unsung Heroes

October 4, 2024

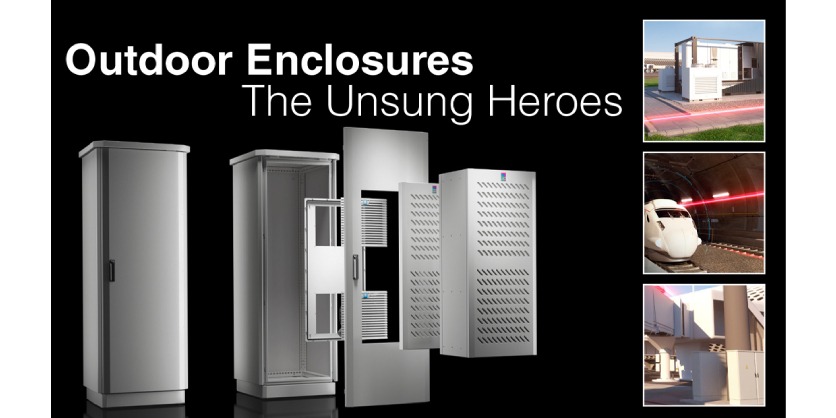

Outdoor Enclosures – The Unsung Heroes

Outdoor enclosures are everywhere—by the roadside, on sidewalks, or alongside railways—and yet they are often overlooked despite their vital role in our daily lives. These seemingly simple metal boxes are responsible for protecting highly critical equipment that ensures the smooth operation of essential infrastructure, such as telecoms, utilities, and transportation systems. Without them, the flow of information and services we rely on could be compromised.

These enclosures serve multiple purposes: they must be functional, flexible, durable, secure, and, in some cases, aesthetically pleasing to blend into urban environments. More importantly, they must be resilient, often enduring harsh weather conditions for years. While outdoor enclosures may seem basic, they are, in fact, a marvel of engineering and innovation, designed to meet stringent requirements while ensuring the protection and longevity of the equipment they house.

The Demands of Outdoor Enclosures: More than Just a Box

Designing outdoor enclosures is far from straightforward. Unlike indoor environments, outdoor applications present a wider range of challenges that need to be addressed, including exposure to extreme weather conditions, temperature fluctuations, and security threats. Let’s explore the various elements that make these enclosures an engineering triumph.

Weather Resistance: Battling the Elements

The most obvious challenge for outdoor enclosures is the weather. Exposure to heat, humidity, rain, wind, snow, and ice means that the materials and design of the enclosure must be able to endure the full spectrum of climate extremes. In the summer, enclosures can face high temperatures and intense solar radiation, leading to potential overheating of internal equipment. In the winter, they need to withstand freezing temperatures, wind, ice, and snow.

At Rittal, they use powder-coated aluminum for their enclosures, which not only protects against corrosion but also provides durability in a wide range of temperatures. However, Rittal takes it a step further with their double-skin construction. This dual-layer design offers several key advantages:

- Temperature Management: The outer layer acts as a protective barrier, reducing the impact of direct sunlight and preventing excessive heat buildup. During colder months, it helps retain internal heat, keeping equipment at optimal operating temperatures without consuming additional energy.

- Enhanced Durability: The double-skin design improves the enclosure’s ability to withstand impacts, be it from environmental debris or accidental damage. It also provides extra insulation, allowing passive or active cooling systems to operate more efficiently.

- Serviceability: The outer skin can be easily replaced if damaged, while the inner layer continues to protect the internal components. This modularity reduces costs and downtime, as there is no need to replace the entire enclosure when only the outer shell is compromised.

Protection Against Ingress: Keeping Out Water and Dust

Outdoor environments can be unforgiving when it comes to water and dust intrusion. Ensuring that the enclosure remains sealed and impervious to these elements is critical for maintaining the integrity of the equipment inside. The Ingress Protection (IP) rating system is used to define the level of protection against these elements.

For outdoor enclosures, Rittal recommends a minimum IP55 rating, which ensures protection from dust and water ingress, even during heavy rain or wind-driven storms. This rating provides peace of mind that the equipment inside remains dry and free from dust particles, which could otherwise interfere with sensitive electronics.

But an IP rating alone isn’t enough. The design of the enclosure must prevent standing water from accumulating, especially around the seals. If water is allowed to pool on the enclosure, it can lead to degradation of the seal material over time. In colder climates, freezing water can expand, creating gaps between the door and the housing, ultimately leading to leaks.

Rittal’s enclosures are designed with overhanging roofs and drainage channels to ensure that water runs off, protecting the seals and preventing any potential leaks. This is especially important for enclosures located in areas with high precipitation or near coastal environments where saltwater exposure can be particularly corrosive.

Security: Keeping Equipment Safe in Public Spaces

Outdoor enclosures are often placed in public areas, making them vulnerable to tampering, theft, and vandalism. Therefore, security is a paramount concern, especially for enclosures that protect critical infrastructure, such as telecommunications systems, power grids, and transportation networks.

The level of security required depends on the location and application. For enclosures in busy urban areas or remote locations, robust locking mechanisms and tamper-proof designs are essential. Rittal offers a range of security features, including:

- Specialized Locks: High-security locks that prevent unauthorized access. These locks can be customized based on the specific requirements of the client, including key-based systems, combination locks, or electronic access control.

- Remote Monitoring: Some applications may require remote access and monitoring capabilities, allowing facility managers to check the status of the enclosure and ensure it remains secure, even from afar.

- Reinforced Construction: Rittal’s enclosures are designed to withstand attempts at forced entry, with reinforced doors, frames, and hinges providing an additional layer of security.

Whether placed in a remote area, a busy city center, or even an airport runway, limiting access to the equipment inside is crucial. Security features ensure that only authorized personnel can access the enclosure, reducing the risk of sabotage or accidental damage.

Future-Proofing with Flexible Internal Design

While the exterior design is focused on protecting the enclosure from the elements and unauthorized access, the internal design must offer versatility and flexibility. Technology is constantly evolving, and outdoor enclosures must be able to accommodate new systems without requiring complete replacement.

Keeping Up with Technological Advances

Technology evolves at a rapid pace, and in some cases, by the time a system is deployed, it may already be outdated. This is particularly true for telecommunications and networking equipment, where advancements are frequent. Designing an enclosure with a flexible internal structure allows for future upgrades without the need for significant modifications.

Rittal’s enclosures offer modular mounting systems, enabling clients to easily swap out or upgrade components as technology changes. This flexibility reduces downtime, lowers labor costs, and ensures that systems remain online as much as possible. By future-proofing the enclosure, clients can avoid costly retrofits and replacements down the line, keeping their infrastructure ahead of the curve.

The Growing Need for Outdoor Systems

As the world becomes increasingly connected, the demand for outdoor systems continues to grow. Smart cities, 5G networks, and IoT (Internet of Things) applications all require robust outdoor enclosures to house the critical infrastructure that powers these innovations. Whether for telecoms, rail networks, airports, or highways, the demands remain the same: protection, security, and flexibility.

With the ever-expanding requirement for connectivity and automation, outdoor enclosures will play an even more critical role in the future. From housing 5G equipment to protecting data centers in remote areas, these unsung heroes will continue to ensure the reliability and resilience of our most critical systems.

Conclusion: The Vital Role of Outdoor Enclosures

Outdoor enclosures are far more than simple metal boxes—they are engineered solutions designed to withstand the elements, secure critical equipment, and adapt to future technological needs. With thoughtful design, robust materials, and advanced security features, outdoor enclosures ensure the uninterrupted operation of essential systems that power our modern world.

As technology continues to evolve and the need for connectivity increases, the role of outdoor enclosures will only become more significant. Whether it’s protecting telecom networks, ensuring power grid stability, or enabling the latest smart city applications, these enclosures are the unsung heroes that keep our infrastructure running smoothly and securely.

Related Story

Outdoor Enclosures: Aluminium vs. Stainless Steel – Which is Best for Your Application?

When selecting an enclosure for outdoor environments, stainless steel has long been the go-to material. But is it always the best choice? Increasingly, aluminum is being recognized as a viable, often superior option, especially when factoring in weight, durability, cost, and corrosion resistance.