OnRobot’s VGP30 Gripper Strengthens the Hardware Behind Off-The-Shelf Solutions

April 11, 2025

By Krystie Johnston

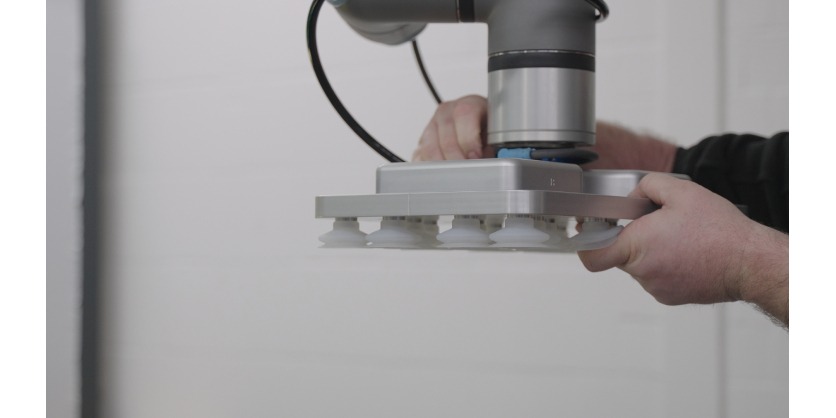

OnRobot was founded in 2018 with the mission of breaking down barriers to automation so manufacturers of all sizes can reap these benefits. They have a wide product portfolio of hardware and software solutions for collaborative applications that cover major industries, all hallmarked with easy integration, quick changeover capabilities, and compatibility with most major cobot brands. The latest addition in their product portfolio is the VGP30, their highest payload vacuum gripper designed for enhanced collaboration automation.

“It makes a nice addition to the overall OnRobot portfolio,” says James Taylor, CCO of OnRobots. He oversees commercial and regional activities, from sales to marketing, and field support too. The VGP30 is their newest addition in the vacuum gripper lineup, which includes products like the VGP20, an electric vacuum gripper, and the VGC10, a more compact electric vacuum gripper. “I would not call it an upgrade. I would call it a different application focus. As we increased the vacuum capacity, we focused the VGP30 on the higher payload.”

A look at the features and benefits of OnRobot’s grippers

The VGP30 has two channels, or independent picking zones, and uses compressed air to achieve a higher payload. The VGP20 is an electric vacuum gripper, and has four channels, or independent picking zones, offering maximum flexibility. The VGP20 has a slightly higher upfront cost but lower operating cost compared to the VGP30 because they have a different application focus. “It [the VGP30] is really a different segment. The customer that needs the higher payload, that true 30kg payload for their application, this is where the VGP30 comes into play,” says Taylor.

The VGP30 has the same benefits as the entire OnRobot portfolio: quick changeover, easy integration, and plugins with all major cobot brands. But it also has unique features that address the higher payload: two channels or picking zones offer flexibility with a wide range of box sizes, enabling it to grip one or more boxes without having to reconfigure. And the suction cups are a bit offset from the centre. “Usually, tape goes down the middle of the box, so it is meant to kind of offset a little bit to get on the true cardboard without tape interface,” explains Taylor.

Like all OnRobot vacuum grippers, it is easy to switch the suction cups that are used when the application requires a change. “If you have different materials – different types of cardboard, different types of boxes – you can choose a different suction cup for your particular application,” explains Taylor. And it has intelligent vacuum control.

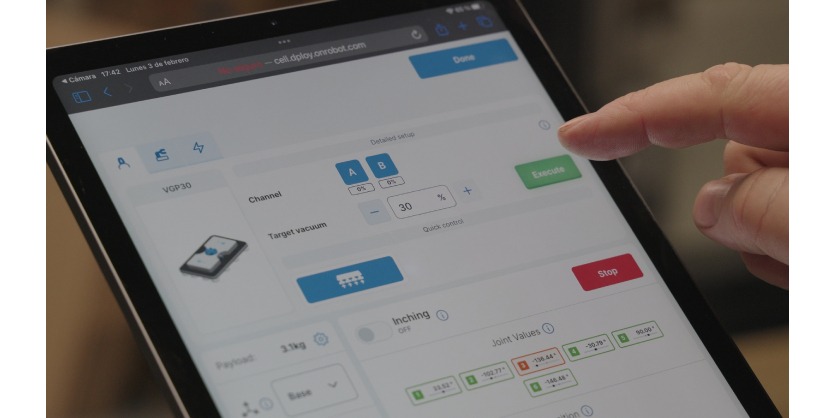

“It also offers configurable vacuum levels to grip both heavy boxes with high power and thin paper inner layers with lower power. That means you are not using too much when you do not need it and not using too little when you do need it. That is really good for power consumption and overall airflow consumption.”

The VGP30 is not only powerful, but also lightweight compared to other grippers in its class. Taylor says it comes in at around 3.1 kg (6.8 lbs). “Having compressed air allows us to dramatically increase the power. It has a max airflow of 440 litres per minute and a max bar pressure of seven. I think we have a pretty powerful gripper, which is number one,” says Taylor.

“Number two is, different suction cups perform differently on different types of materials, and the design that we have is a very quick and easy change out. So, you can customize both the suction cups and the configuration of the suction cups, adding more power and more direction to one set or a smaller set.”

Perhaps that biggest selling point of the VGP30 is that it is ready to deploy, right out of the box. “We have plugins for the major cobot brands,” says Taylor. “UR, FANUC, DOOSAN, Techman, Omron, JAKA, and so on. It is pop-in-ready-to-go. The smart controls are integrated inside the gripper. And if you already have compressed air in the factory, it is a simple hookup.”

Off-The-Shelf Solutions are the future of automation

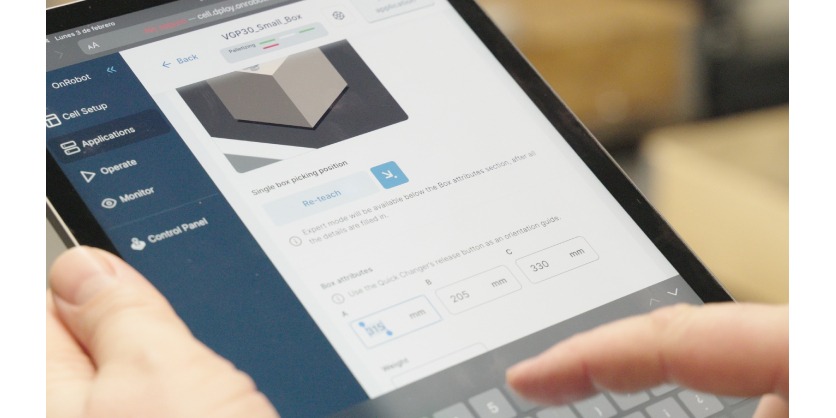

Taylor believes their Off-The-Shelf Solutions are where the future of automation is headed. An Off-The-Shelf Solution from OnRobot is a fully pre-engineered, application-specific robotic system—such as for palletizing or machine tending—that includes all necessary hardware, software, and components in one standardized package.

Built and powered by D:PLOY, these solutions are designed to be installed and up and running on the same day, with no programming required. They come with transparent pricing, clearly defined performance specifications, and the ability to switch between workpieces in minutes, making them ideal for high-mix, low-volume production environments.

Developed and delivered through local OnRobot partners, these solutions combine the speed and simplicity of plug-and-play automation with the flexibility and control manufacturers need to scale—without needing robotics expertise or complex integration.

Time is money, as the adage goes, and many businesses today do not have the capability or capacity to implement robots and automation, and they are not able to endure re-automating their processes when a change is needed. At the same time, to remain competitive, they cannot afford not to. This is where OnRobot’s automated solutions come in. “When we say ‘out-of-the-box, it really means you do not need to spend [days] trying to figure out how it works. It is ready to go.”

OnRobot’s Off-The-Shelf Solutions boast same day installation – a claim that they make intentionally because they stick the landing every time. Their portfolio provides customers with automation that is accessible, flexible, and effective, and it makes robotic automation possible for manufacturers of all sizes. “That value in being able to set up quickly, be able to do changeovers quickly, is minimizing downtime. And for a manufacturer, production is how they make their money. To me, that is the most important core value.”

D:PLOY is their platform for automating collaborative applications, enabling systems to be deployed within hours – not days, or weeks. D:PLOY enables deployment right on the manufacturing floor, without the need to program or simulate the process. It also liberates the customer or end user from the obstacles of automating an application when they need to re-deploy it, because they can do this themselves.

Taylor says that for customers, the value of being able to re-deploy the hardware and software when and as needed, is the key to unlocking automation. “Because they do not need to program, because they do not need any kind of engineering skills, because it is automated, they can change from box A to box B to box C to box D, very quickly, without any kind of expertise needed. That value unlock is the last big barrier to using robots and automation.” And for Taylor, this is where the future of automation is headed.

One Stop Shop for collaborative applications

OnRobot is ushering in a paradigm shift. Where automating has typically been cost-prohibitive to small-to-medium enterprises, their hardware and software offering is making it attainable, with transparent pricing so that everything is straightforward. Their products and solutions are provided through more than 700 distribution and systems integration partners. For Taylor and OnRobot, partnerships are fundamental to carrying out their mission. “We are a global company but act locally. We have, as a company, invested in organizations in every major manufacturing market.”

OnRobot is based in Odense, Denmark, but their footprint spans the globe with their offices all over the world and a network of distribution and integration partners. “We have a team of people in the US, we have a team of people in Japan, we have people in Korea, Singapore, Germany, [the] UK, and Spain. We know that at the end of the day, business is done between people, and we make sure that we have people in the same time zone that speak the same languages, that have the same cultures, to support our partners. That is where we spend a lot of time and money.”

Investments in partnerships and practical product solutions are clearly working for OnRobot, and their customers as well. Taylor says it is refreshing for customers to be able to have Off-The-Shelf Solutions for collaborative applications that they can re-deploy themselves in minutes. Not a turn-key solution that is complicated and expensive to initiate, and limited to a single application, but a true ‘unlock’ for automation.

Traditional turnkey solutions often involve hidden costs, long lead times, and the need for robotics expertise to deploy and adapt. Off-The-Shelf Solutions, powered by D:PLOY, are pre-engineered, transparently priced, and installed the same day.

They enable fast changeovers in minutes – without programming – making automation truly accessible for manufacturers of all sizes. “It’s automation without the complexity, risk, or surprises,” concludes Taylor.

About James Taylor

James Taylor is Chief Commercial Officer at OnRobots in the Odense, Region of Southern Denmark. He has a strong track record in delivering rapid revenue growth, developing sales teams, distribution networks, and designing-executing effective go-to-market strategies in both small startups and large multinational companies.

More Information

Dutch Distillery Automates Palletizing – Up and Running Within One Day

Related Story

OnRobot Drives Market Growth With Groundbreaking D:PLOY Platform

Delivering on its mission to break down automation barriers and bring the benefits of collaborative automation to businesses of all sizes, OnRobot has launched D:PLOY, its highly anticipated flagship platform, for worldwide availability. D:PLOY is the industry’s first automated platform for building, running, monitoring, and re-deploying collaborative applications. By automating the process of getting a robotic application up and running, D:PLOY allows complete applications to be deployed and redeployed directly on the manufacturing floor in a few simple steps, with zero programming – all within a few hours.