How Omron Light Curtains Improve Machine Safety Compliance in Canada

April 16, 2025

In Canadian industrial environments, safeguarding workers and ensuring machine safety compliance is both a regulatory requirement and a productivity necessity. At Proax, as an authorized distributor of Omron, they offer safety solutions engineered to meet and exceed modern compliance standards — including the CSA Z432 and Z434 requirements unique to Canada.

Among these solutions, Omron’s Safety Light Curtains stand out for their reliability, versatility, and full compliance with global and regional safety regulations.

What Are Safety Light Curtains?

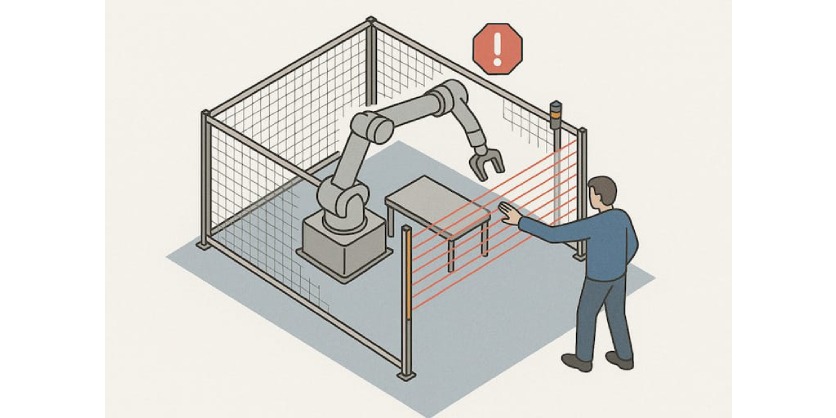

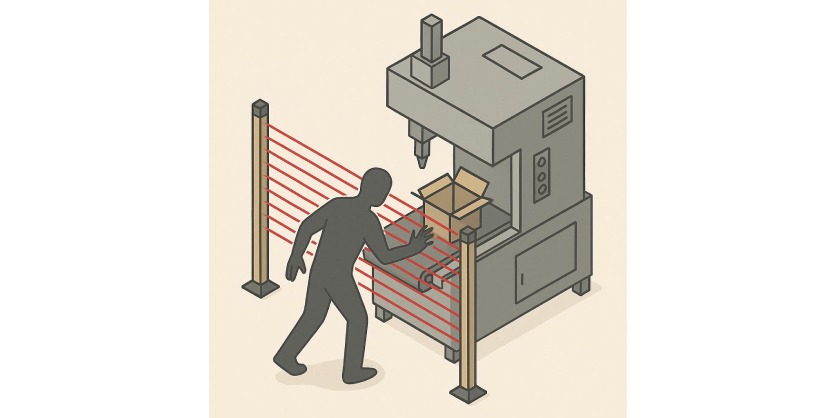

Safety light curtains are presence-sensing devices that create an invisible grid of infrared beams between a transmitter and receiver. When an object or person enters the sensing zone and breaks one of the beams, the curtain sends an immediate stop command to the machine — helping prevent serious injury without physical contact or obstruction.

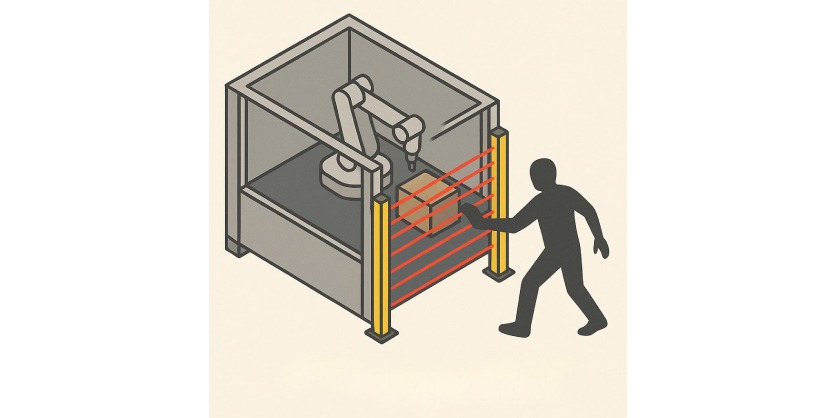

These curtains are especially valuable where frequent access is needed, such as in packaging lines, robotic workstations, or assembly environments, offering non-contact, ergonomic protection.

Common Industrial Applications

Light curtains are used extensively in:

Machine Guarding: CNC machines, stamping presses, injection molding

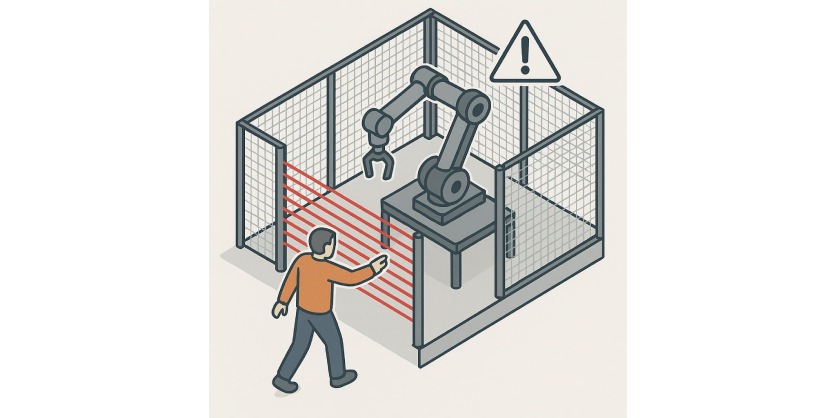

Robotic Cells: Defining safe zones in collaborative robot environments

Material Handling: Preventing collisions on conveyors and automated storage systems

Packaging: Protecting operators around filling, sealing, and wrapping lines

Perimeter Protection: Blocking access to dangerous zones and equipment areas

Canadian Compliance Standards

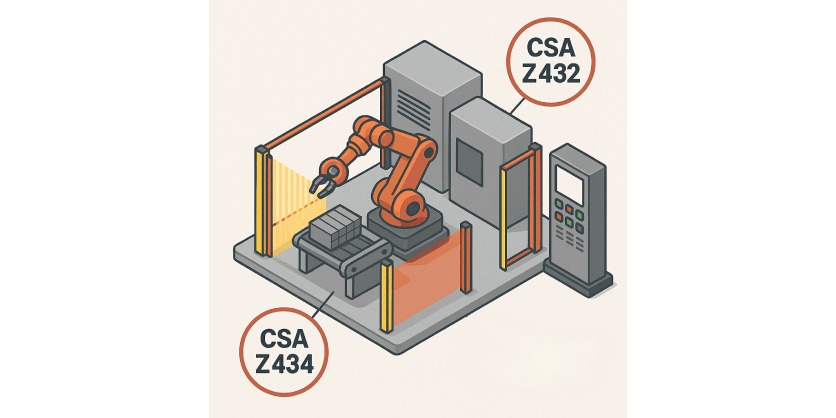

CSA Z432 – Safeguarding of Machinery

This Canadian standard defines the general principles for machinery safeguarding, covering design, installation, and validation of safety systems — including light curtains. Key areas include:

- Risk assessment methodology

- Guarding principles (physical and electronic)

- Minimum performance requirements for safety devices

- Procedures for validating safety functions

CSA Z434 – Robots and Robotic Devices

This standard focuses on robotic safety, including collaborative applications, where light curtains often supplement other safety measures like area scanners and pressure-sensitive mats. It references requirements for:

- Defined safety zones around robots

- Interlocking systems

- Integration with functional safety systems

Together, Z432 and Z434 are essential for meeting provincial OH&S regulations across Canada and are often referenced in workplace safety inspections.

Other Global Safety Standards

Omron safety light curtains are engineered to meet the most recognized global benchmarks:

| Standard | Description |

|---|---|

| ISO 13849 / IEC 62061 | Define performance level (PL) and safety integrity level (SIL) for machine safety systems |

| IEC 61496-1 / 2 | Specifies design and test criteria for electro-sensitive protective equipment |

| ANSI B11.19 | North American standard for safeguarding devices and system performance |

| ISO 13855 | Specifies minimum installation distances to ensure safe stopping before hazard access |

These standards ensure that your safety system performs as expected in terms of response time, redundancy, fault detection, and environmental resilience.

Feature Overview: Omron F3SG Series Light Curtains

F3SG-SR Series Safety Light Curtains

Omron’s top-tier safety curtain with Type 4 performance, suitable for high-risk applications. Features include:

- SIL 3 / PL e rated

- Long-range detection

- IP67G/IP69K protection for harsh environments

- Alignment assistance and diagnostic LEDs

Ideal for: automotive, metal stamping, material transfer zones.

F3SG-RE Series Safety Light Curtains

Cost-effective safety curtain with Type 2 protection for lower-risk environments. Features include:

- PL c rating

- Slim body for easy integration

- Designed for basic hand protection applications

Ideal for: packaging, semi-automated workstations, general machinery.

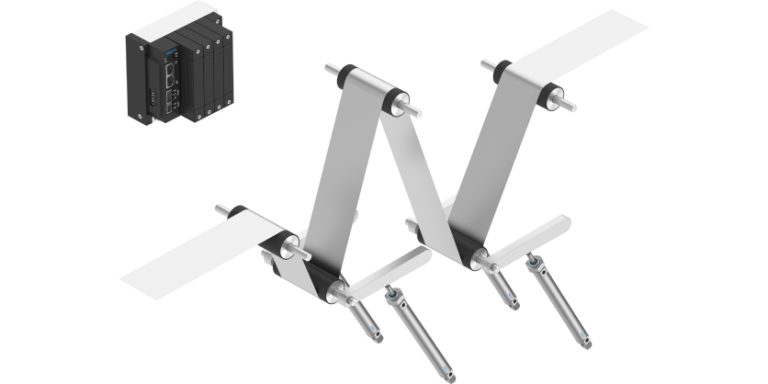

Additional Series

- F3SJ-A Advanced Safety Light Curtain

- F3SJ-B Basic Safety Light Curtain

- F3SG-PG for perimeter guarding

To support installation, configuration, or maintenance, visit Proax’s full range of Safety Light Curtain Accessories, including cables, intelligent tap units, and sockets.

Why Use Light Curtains Instead of Traditional Guards?

| Feature | Light Curtains | Traditional Guards |

|---|---|---|

| Non-contact detection | ✅ Yes | ❌ No |

| Response time | ✅ Milliseconds | ❌ Slower, operator-dependent |

| Accessibility | ✅ High | ❌ Often obstructive |

| Ergonomics | ✅ Unrestricted access | ❌ Poor for frequent access |

| Compliance | ✅ Meets PL e / SIL 3 | ❌ May fall short of new standards |

| Flexibility | ✅ Reconfigurable | ❌ Rigid design |

Omron light curtains not only improve operator safety, they also support better machine uptime and easier maintenance access — all while staying fully aligned with current and future Canadian regulatory expectations.

Final Thoughts

For Canadian manufacturers and industrial operators, staying compliant with CSA, ISO, and IEC safety standards is critical — not just to pass audits, but to ensure a safe, productive work environment. Omron safety light curtains, available through Proax, are built to help you meet these standards confidently.

✔ Certified to meet the world’s most stringent safety expectations

✔ Available in multiple models to suit every risk level

✔ Backed by Proax’s in-house safety specialists, certified in TÜV and ANSI standards

✔ Fully supported by local inventory, technical support, and application expertise

Contact them to connect with Proax’s certified safety team and build a compliant, future-ready safety system.

Related Story

Transform Your Operations with Sysmac Automation – Powered by Proax

Discover how Omron Sysmac Automation Solutions, brought to you by Proax, can revolutionize your operations. With seamless integration, faster deployment, and unmatched scalability, it empowers you to tackle the toughest challenges in automation.