Omron’ Advanced Safety Services 101

Omron Offers Advanced Safety Services – What You May Not Know Yet

April 10, 2024

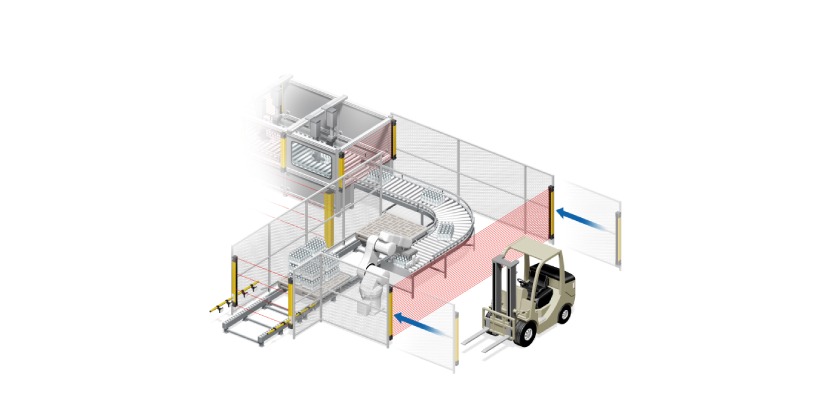

In any industrial setting, safety is of the utmost importance. Omron Offers Advanced Safety Services to help you and your staff navigate the challenges of complex industry standards and compliance regulations. They also can provide machine safety technology to protect your people and equipment while maximizing productivity.

Did you know that Omron’s safety training and services encompass safety compliance education, risk assessment, and compliance reviews led by certified safety engineers? Their enabling technologies Include Functional Safety Training, Machine Safety Risk Assessments, Machine Safeguarding Solutions, Lockout/Tagout Procedures, Arc Flash Assessment, And Machine Safety. In this blog, Omron experts provide details about how they can help businesses safeguard workers, maintain stable operations, and prolong equipment life cycles.

What are some of the Advanced Safety Services Omron has to offer?

Omron’s Advanced Safety Services are comprehensive and relevant to many industries where machines are automated, or workers need to operate equipment.

Their training offering ranges from Machine Safety Skillbuilder, which is a live-streaming, instructor-led online course that focuses on the basics of machine safety and machine guarding, to focused courses such as their TÜV Rheinland Functional Safety (FS) Engineer and TÜV Rheinland Functional Safety (FS) Technician offering, where, after extensive training, qualifying participants can receive a certificate and become registered as a TÜV Rheinland FS Technician or Engineer themselves.

For existing machinery, Omron’s team offers a holistic solution for machine safety, starting from machine guarding assessments, engineering design, and full turnkey remediation services. For new machines, they partner with OEMs and end users to leverage their safety and engineering expertise to eliminate hazards during the functional design of the entire system. This ensures their customers receive machines that are safe from the beginning. Greenfield or brownfield, Omron has a portfolio of solutions and services that will ensure your business operates safely.

How long has Omron been offering advanced safety services? How often are they refreshed or modernized?

Omron’s Safety Services team has more than 35 years of experience offering safety services. During this time, they have made more than 15,000 machines safe. Omron’s team has more than 60 American-based participants on Global Safety Committees (ANSI, ISO, RIA, etc.), and they have adopted their safety solutions and trainings as safety standards evolve. In this way, Omron maintains safety services that are current and relevant by keeping up to date with the most current standards and regulations – both locally and internationally – allowing them to provide the most comprehensive solutions to their customers.

Where Are Omron’s Safety Services Available?

Omron Safety Services operate around the globe and have distinct teams in different regions. Most of their training offered in North America can be completed online or in person. Their machine guarding services, such as Risk Assessments & Remediation are typically provided on site, with exceptions.

Who is Omron’s Advanced Safety Services designed for? And how often should they repeat or retake these courses?

It depends on the training course. The Safety Skillbuilder should include Environmental Health & Safety (EHS), Maintenance personnel, Plant Managers, and any other stakeholders involved with machine safety. TÜV FS Technician Training should include Technicians Engineers and Health and Safety professionals who are responsible for supporting existing safety systems. TÜV FS Engineering Training should include Engineers and professionals who are responsible for machine safety design or engineering reviews.

What third-party expert certifies this training?

Omron’s Functional Safety Training offerings are certified by TÜV Rheinland. Once the training is completed, there is an exam that offers certification to become a certified TÜV Rheinland Functional Safety Engineer or Technician yourself. There are 17 TÜV Rheinland Certified Functional Safety Machinery Experts located around the world – and Omron has three of them on their team.

What are some of the safety-related products that Omron has for the Food, Beverage, and Commodities industries?

- F3SG-SR Light Curtains – invisible barriers for presence detection (available in IP67 and IP69K variants)

- OS32C Safety Laser Scanner for presence detection

- ER1022 E-stop Rope Pull to stop equipment in an emergency

- A22NE-PD – E-Stop switch to stop equipment in an emergency

- D41D High Coded No-contact door switch for access doors into guarded areas

- G9SE and G9SX safety relays for safety rated stopping and starting of equipment

- NX-SL5 Safety Controller to control safety operations based on input from safety devices like light curtains or laser scanners

More Information

Case Study: How Omron Helped Kerry Foods with New Safety Standards

Kerry Foods in Sainte-Clair, Quebec uses Omron automation and safety systems in their plant to protect their most valuable assets… their employees, their machines and their product integrity. Kerry Foods’ dedication to exceeding Canada’s strict safety regulations brought their safety committee together with Omron’s TÜV functional safety engineers to create a program that is second to none… a practical and reliable safety system that eliminates barriers to production and prevents downtime due to manual intervention.

Success Story: Omron Controls Helps Saginaw Bakeries with Tray Stacking System

Saginaw Bakery wanted to improve productivity, reduce product damage and eliminate the potential for injury caused by manual tray stacking in delivery preparation. The company worked with automation solution providers to develop a fully automated tray stacking system using Omron control and safety technologies that can stack any collection of industry-standard bread baskets at a speed of 15 trays per minute. The new tray stacking system’s speed provided a 25% improvement in the productivity of a three-person stacking crew and allowed these employees to take care of other tasks while also protecting them.

Related Story

Omron’s K6PM Thermal Condition Monitor: Predictive Maintenance Reduces Downtime

Effective and exhaustive temperature monitoring has traditionally been performed by skilled workers who are adept with using special thermal monitoring equipment to identify potential concerns. These inspections, however, are becoming increasingly complicated because of the ever-increasing number of devices in a panel that are needed to adhere to compliance standards. Simultaneously, the quality and quantity of maintenance workers is receding, making it challenging to provide real-time analysis of thermal conditions in a panel and develop an accurate snapshot of the system.