Innovations in Terminal Blocks: Towards More Efficiency and Sustainability

December 10, 2024

In this rapidly changing world of industrial automation, the terminal blocks remain some of the unsung heroes. Small but mighty, they make sure that connections are seamless and that all machinery and systems which constitute modern industries are running smoothly. But like everything else in technology, they too have not remained static. Very recently, innovations seek to not only make them more efficient but sustainable and smarter than ever before.

Innovations Driving the Future of Terminal Blocks

- Eco-Friendly Materials

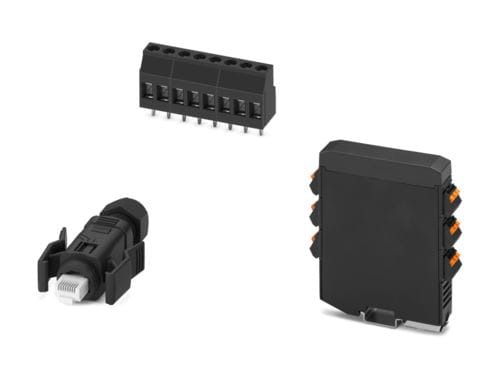

Sustainability is a key building block for modern manufacturing, and Phoenix Contact is no exception. With the application of bio-based plastics from renewable sources, such as those derived from castor beans, Phoenix Contact has managed to reduce its carbon footprint without compromising on durability and performance. The resulting bio-based components are both eco-friendly and able to withstand extreme industrial conditions, allowing you to go green without having to make a choice between sustainability and functionality. For example, the first solutions with optimized sustainability are already available in the product categories of PCB terminal blocks and connectors.

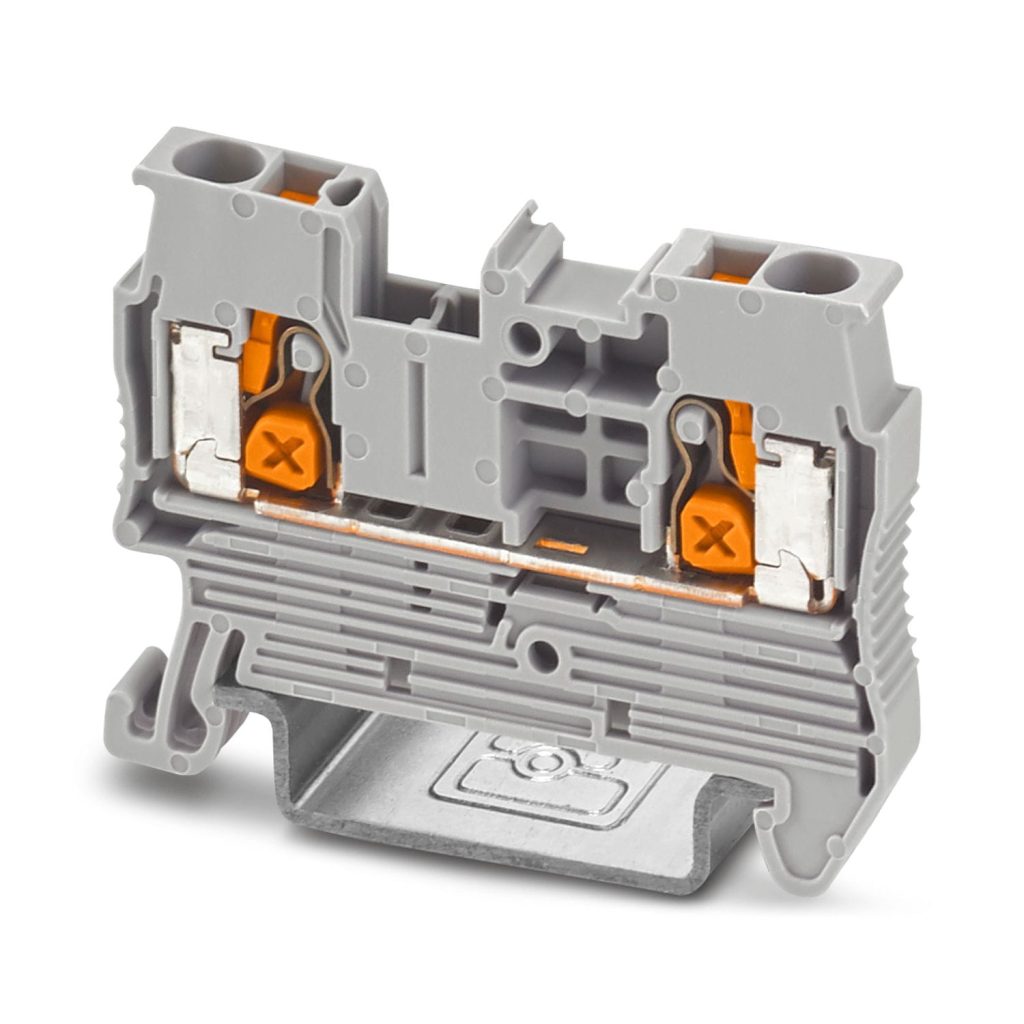

- Push-In Technology for Faster Connections

The most impressive innovation of terminal blocks is Push-in Technology, which has made installation easier. Engineers can directly insert wires without using any tools, reducing assembly time by up to 50%. This is very important when it comes to high-volume applications. Push-in connection terminal blocks also offer reliable and vibration-resistant performance, thus making them highly suitable for dynamic environments such as automotive manufacturing and robotics.

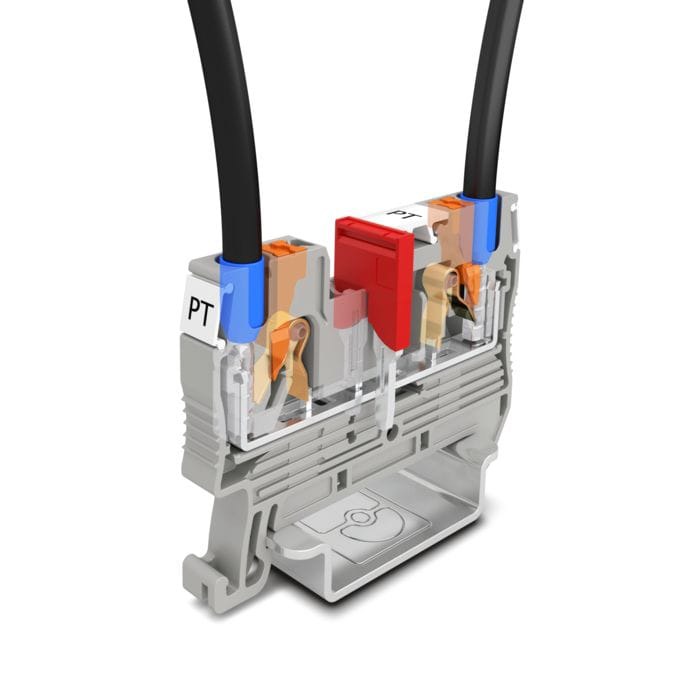

- Smart Terminal Blocks: Push-X Technology

The latest innovation in terminal blocks, Push-X Technology, revolutionizes wiring by combining speed, efficiency, and ease of use. The new XT terminal block family is engineered to handle conductor cross-sections of 0.5 to 4 mm², ensuring effortless and tool-free wiring for both rigid and flexible conductors—with or without ferrules.

4.Enhanced Modular Designs

Modern terminal block systems have revolutionized connectivity through innovative modular designs. The CLIPLINE complete system exemplifies this evolution with its uniform range of accessories that work seamlessly across all connection technologies. This standardization allows engineers to freely combine different connection methods while using consistent bridge accessories, marking materials, and test components.

The double function shaft enables standardized accessory use across various terminal blocks, while reducing bridges make it possible to combine different cross-section versions efficiently. These advancements significantly reduce inventory complexity and installation time, making terminal block systems more adaptable and cost-effective than ever before.

5.Safety-First Terminal Blocks

Safety innovations in modern terminal blocks protect both operators and equipment through multiple integrated features. Touch-proof connector designs and the Reakdyn screw locking mechanism ensure secure, maintenance-free connections. LED status indicators provide quick fault detection, while sophisticated coding prevents mismatching components.

For specialized environments, ATEX certification ensures safe operation in explosive atmospheres, while EMC protection through shield clamps guards against electromagnetic interference. The spring-loaded contact points maintain stable connections even under railway-standard vibration conditions, and clear visual indicators enable operators to verify switching states at a glance. These safety features combine to create more reliable and secure electrical connections while reducing maintenance requirements.

Related Product Series

PTTB Push-in connection Series

Why Choose Phoenix Contact Terminal Blocks from Proax?

As an authorized distributor of Phoenix Contact, Proax provides access to the latest and most reliable terminal block technologies. What sets Phoenix Contact apart is its dedication to innovation, quality, and sustainability. Here’s what you get when you choose Phoenix Contact terminal blocks through Proax:

- Durability: Designed to withstand harsh conditions and environmental contaminants.

- Flexibility: A wide range of connection technologies to suit any application.

- Sustainability: Eco-friendly materials and energy-efficient manufacturing.

- Reliability: Proven performance backed by rigorous quality testing.

Proax doesn’t just sell terminal blocks—they provide solutions. Whether you’re upgrading your system, optimizing your control panel, or embarking on a new project, their in-house engineering team is there to help. Explore their comprehensive range of Terminal Blocks, or check out their Ultimate Guide to Terminal Blocks or download phoenix contact terminal blocks pdf for in-depth insights.

Terminal blocks may be small, but their impact on industrial automation is massive. With advancements in materials, design, and technology, they’re more efficient, sustainable, and versatile than ever. By choosing innovative solutions like Phoenix Contact’s terminal blocks from Proax, you’re investing in reliability and future-ready performance.

Ready to upgrade your connections? Contact Proax today and let them guide you to the perfect solution for your needs. Together, you can build the future of industrial automation.

Related Story

10 Most Common Applications of Aluminum Extrusions in Manufacturing

Discover how leading manufacturers are leveraging aluminum extrusions to enhance their production capabilities. This guide explores the most common applications of industrial aluminum profiles and precision extrusion systems in modern manufacturing.