Vision Sensors—Use Cases for Industrial Vision in the Automotive Industry (Part 4)

June 26, 2023

The range of tasks for vision sensors in the automotive industry is as diverse as the sensor technology used. The detection of fasteners in automotive construction, optical identification in the high-temperature range, and the detection of components in car body construction are only a few of the use cases for vision sensors in the automotive industry. Learn more about these three examples and the advantages of the vision sensors used in this blog article.

Content of This Article

- Reliable Detection of Fasteners in Automotive Engineering with the SmartRunner Matcher

- Reliable Optical Identification in the High-Temperature Range with the OIT

- Precise Detection of Components for Body Construction with the SmartRunner Explorer

- Are You Still Looking for a Solution for Your Application?

Reliable Detection of Fasteners in Automotive Engineering with the SmartRunner Matcher

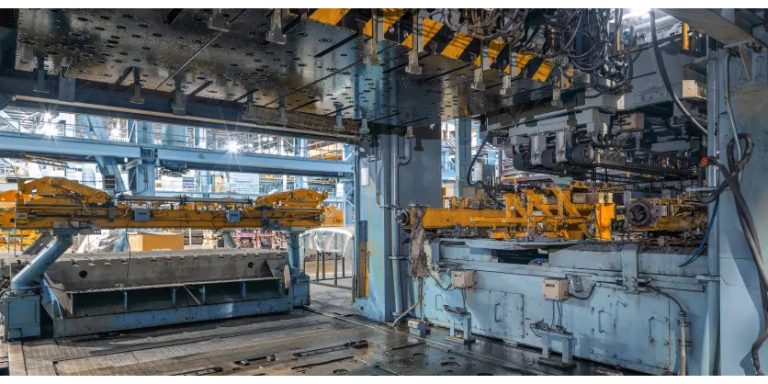

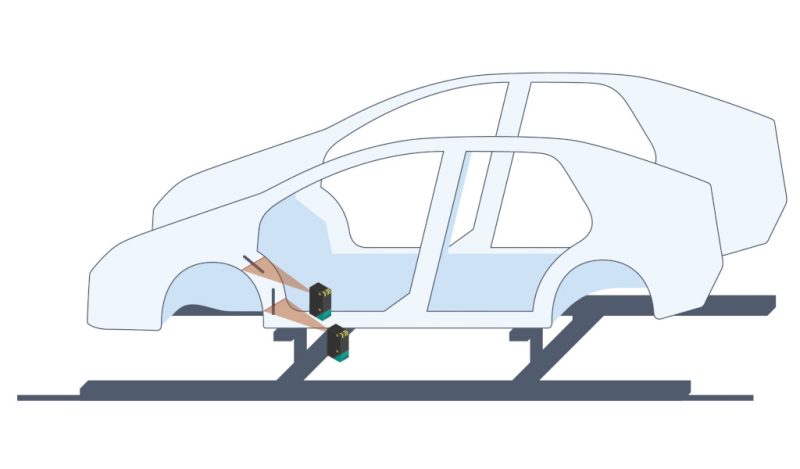

In automotive body and component manufacturing, sheet metal parts, subassemblies and add-on parts are assembled step-by-step to form car bodies. The presence of fasteners such as rivets, screws, clips, and sealing plugs must be verified at various production points. For this purpose, a vision sensor is mounted near the skid or in a robot arm.

The SmartRunner Matcher laser profile sensor is preconfigured for the detection of height profiles. Its laser beam is directed at the objects and the shape and contour to be detected are taught. The inspection is initiated by a trigger. The sensor then detects whether the components are present or missing in the correct position and passes a “good” or “bad” signal to the controller accordingly.

In many cases, the small components are hardly distinguishable from their background. Under these challenging conditions, the SmartRunner is ideally suited for presence detection. It requires no contrast and detects objects even without external light sources, regardless of the object’s color and surface condition. In addition, the SmartRunner Matcher provides the deviation of the current to the taught X and Z position. The sensor can also store up to 32 profiles. Moreover, the very simple parameterization ensures high user-friendliness and fast functionality.

Reliable Optical Identification in the High-Temperature Range with the OIT

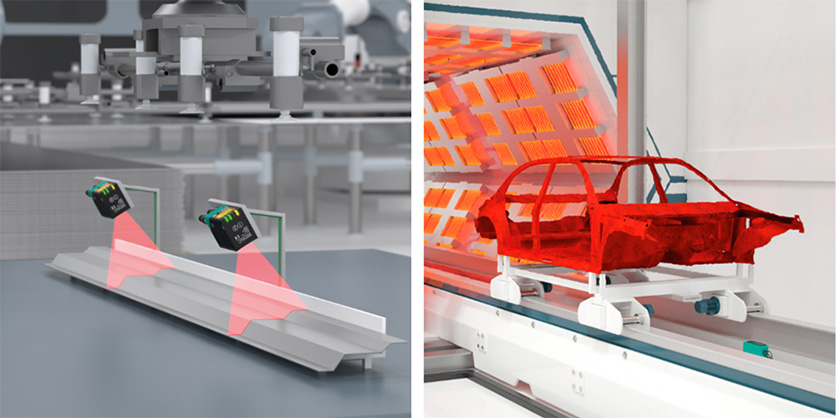

Special conditions prevail in drying systems of paint lines: Cyclical temperature changes, extremely high temperatures, and the effects of dust or paint place high demands on materials and technology. Despite the extreme conditions, reliable identification of the freshly painted car bodies must be ensured when they are transported to the drying plant on skids.

The robust OIT high-temperature identification system from Pepperl+Fuchs ensures smooth process operation even at temperatures of up to 500 °C. Since normal paper labels cannot withstand the high temperatures, punched code sheets are attached under the skid. The special code reader mounted to the system reads these.

The OIT high-temperature identification system guarantees reliable identification of car bodies, even if the code labels are dirty or painted. The integrated infrared side lighting also ensures optimum contrast and makes the system insensitive to ambient light. Simple installation and commissioning enable rapid integration into the application. The system is maintenance-free as a result of the one-piece housing concept with no other add-on parts.

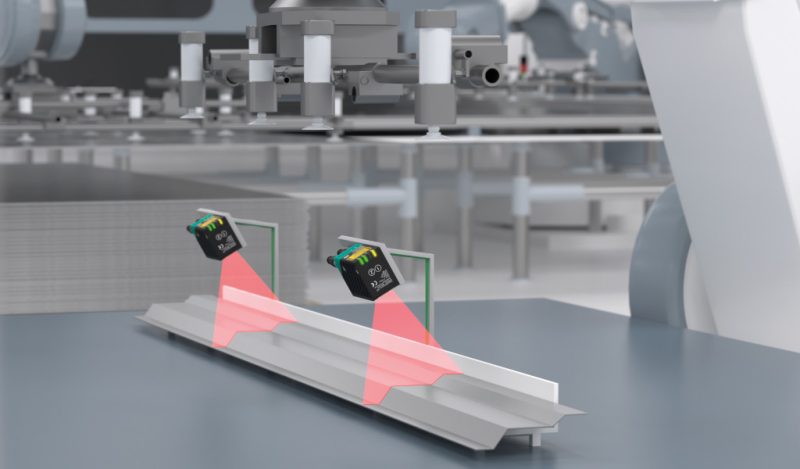

Precise Detection of Components for Body Construction with the SmartRunner Explorer

In car body construction, the formed sheets must remain within narrow tolerance limits in three dimensions. For inspection, the sheets are transported to the test station with the help of a robotic arm. There, the SmartRunner Explorer laser profile sensor records the height profile of the components and passes the data on to the respective quality assurance system, which compares it with the defined specifications.

The SmartRunner Explorer can be easily integrated into the programming environment via an API. It also has an Ethernet TCP/IP interface for connection to an IPC and full access to all parameterization and output data. The SmartRunner Explorer is the only laser profile sensor on the market to offer not only the output of a height profile, but also the ability to generate a 2-D surface image. It detects the components reliably and precisely, even on reflective surfaces such as metal parts.

Are You Still Looking for a Solution for Your Application?

Pepperl+Fuchs offers a comprehensive portfolio of universally applicable vision sensors, application- or customer-specific products, and turnkey solutions. The powerful technologies can be used to solve a wide variety of tasks in the field of industrial vision. Talk to our experts and together we will find the vision product or solution that optimally fits your individual requirements.