How Damage and Distortion Can Impact Barcode Readability

January 13, 2021

Even the most neatly printed or perfectly etched barcodes can eventually degrade to the point of unreadability. As parts move through the various production operations, harsh environmental conditions may cause enough damage or distortion to their barcodes to cause no-reads. Damage can include scratches, tears, blotches, stains, debris and more.

Several environmental factors can contribute to distortion when it comes to terms of shape, contrast, element uniformity, and substrate integrity. For example, temperature changes in a production environment can cause condensation to form on a code, blotching ink or distorting the substrate to a point at which the reader can no longer discern the symbol’s elements.

Fixed pattern damage and related causes of no-reads

Fixed pattern damage refers to any damage to patterns that help a reader determine that a barcode is a barcode. In 2D symbols such as a Data Matrix, this could indicate missing elements in the symbol’s “finder pattern,” which lets the reader discern barcode orientation and count the number of rows and columns. Obstruction can render the barcode unreadable.

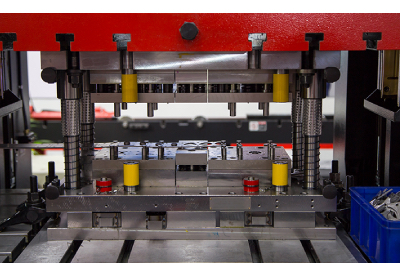

The environmental conditions to which a barcode may be exposed are limitless, and so are the ways in which a barcode can incur damage. Any kind of damage that obstructs barcode elements from the view of the reader – unintended material abrasions, marks, surface stains, or excess material (debris or even mounting fixtures) – can cause no-read results.

Possible solutions for damage or distortion concerns

Once a barcode is released into a production environment, quality can be tough to maintain. In operations that use barcodes to track and identify items even after they’ve been transported between facilities or sold to customers to be read by new barcode reading equipment, options for preventing or resolving barcode damage and distortion are quite limited.

Some preparation can be done at the outset of code production to limit future damage, such as choosing a substrate that’s resistant to harsh environmental conditions, printing or marking barcodes to withstand anticipated environmental factors, and maintaining a production environment as free as possible from potential sources of damage.

It’s often preferable to focus on the capabilities of the barcode reader rather than on the barcode itself. For the most challenging applications, high-performance readers with powerful decoding features (including advanced symbol location, integrated high-performance lighting, gradient or reflectivity analysis, and more) are usually installed from the outset.