Guide to Mechatronics – Part 5: Tools & Languages in Mechatronics Software Development

November 11, 2024

The development of software for mechatronics systems employs a variety of programming languages and tools, each suited to different aspects of the system. The choice of these tools is guided by factors like the system’s complexity, real-time requirements, and hardware specifications.

Programming Languages:

- C/C++: Widely used in mechatronics for their efficiency and control over system resources, ideal for real-time applications and embedded systems. Examples include programming microcontrollers for motor control and robotic arm movement.

- Python: Known for its simplicity and versatility, Python is often used in data analysis, machine learning applications, and prototyping. It is commonly used in vision systems and sensor data analysis.

- MATLAB/Simulink: These are used extensively for modeling, simulation, and algorithm development, especially in the initial design stages. They are particularly valuable in control system design and signal processing applications.

- Java: Used in some mechatronic applications for its portability and robust ecosystem, particularly in networked or IoT-based systems.

- LabVIEW: A graphical programming environment used for data acquisition, signal processing, and instrument control. It is favored in test and measurement applications.

Software Tools:

- Integrated Development Environments (IDEs): Tools like Eclipse, Visual Studio, and Arduino IDE provide comprehensive environments for coding, debugging, and testing software.

- Simulation and Modeling Tools: Software like ANSYS, SolidWorks, and AutoCAD are used for 3D modeling and simulation, crucial in the design and testing of mechanical components.

- Version Control Systems: Tools such as Git and SVN are essential for managing software versions, especially in collaborative projects.

- Real-Time Operating System (RTOS) Platforms: RTOS platforms like FreeRTOS or QNX are used to manage the execution of real-time tasks in embedded systems.

- Data Analysis and Machine Learning Libraries: Libraries like Pandas, NumPy, and TensorFlow are used for advanced data analysis and implementing machine learning algorithms.

Use-Cases:

- Automated Manufacturing Systems: Use C++ or Java for real-time control and Python or MATLAB for data analysis and machine learning algorithms.

- Robotic Systems: Implement control algorithms using MATLAB/Simulink, with C/C++ for programming the embedded systems that control actuators and sensors.

- IoT Devices in Mechatronics: Utilize Java or Python for managing network communications and data processing.

In the field of mechatronics, the software tools and programming languages chosen must align with the specific requirements of the system being developed. While some languages are suited for low-level, real-time control, others are better for high-level data processing and analysis. The versatility and adaptability of these tools are key to the successful implementation of complex mechatronic systems.

Stay tuned as Electromate releases more of their Introduction to Mechatronics series each week.

This article is original content created and posted by Electromate. Please do not re-post this content without prior approval from Electromate.

Related Stories

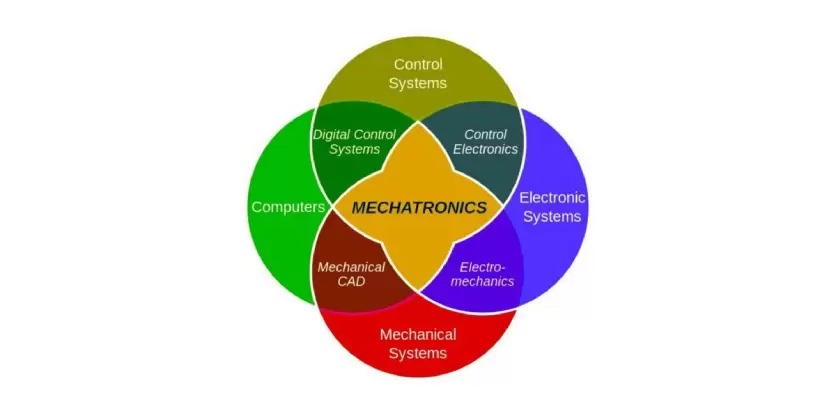

A Guide to Mechatronics – Part 1: Introduction & Fundamentals

A Guide to Mechatronics – Part 2: Composition of a Mechatronic Subsystem

A Guide to Mechatronics – Part 3: Strategies for Integrating Mechatronic Subsystems