Flexible Safeguarding of Special Purpose Machinery

September 30, 2021

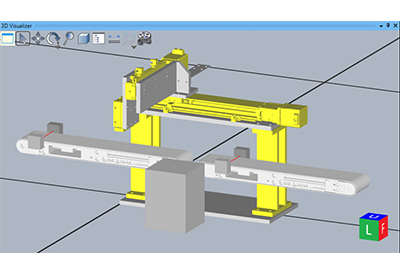

Before a new assembly cell for shock absorbers was due to go into operation at a well-known car manufacturer’s, the special-purpose machinery manufacturer HAHN Automation needed a sophisticated safety concept. As a long-time partner, Pilz used the risk assessment as a basis for developing a flexible solution to safeguard the assembly cell; a solution that could be transferred to other plants.

A safety concept that follows the building block principle

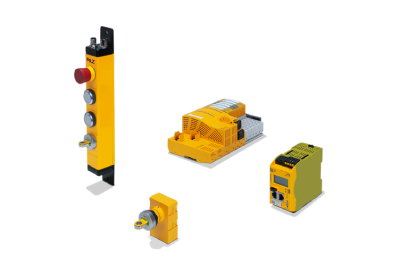

The risk analysis from Pilz showed that appropriate protective measures needed to be taken on the assembly cell for the two intervention areas as well as the five maintenance flaps. As the required safety solution was to be flexible, modular and expandable for use on similar plants, the decision went in favour of the configurable small controller PNOZmulti 2. With its modular hardware platform and a wide range of expansion modules, it covers the safety and monitoring functions. The small controller is simple to operate via the PNOZmulti Configurator; the whole safety concept can easily be implemented on the PC. The intervention areas are secured by the coded, non-contact safety switch PSENcode and a pair of light curtains. The equally non-contact safety gate system PSENslock is used to monitor the safety gates. Hahn Automation can be flexible, also transferring this sophisticated safety solution to future assembly cells.

The benefits at a glance:

- – Safety solution is flexible, modular and expandable

- – With a modular hardware platform and a wide range of expansion modules, PNOZmulti 2 covers all the required functions

- – Solution comprising controller, safe sensor technology and decentralised periphery connection meets the highest safety requirements

“With Pilz we have a long-term equal partner, who gives us reliable support on all issues related to safety. Our electrical engineering staff are very well trained, but aspects surrounding the standard DIN EN 13849 are very complex. With Pilz we have a competent partner for all questions regarding technology, products and efficient solutions; a partner who works with us to create the best possible customer solution” says Dirk Scherer, Team Leader for Electrical Design.