Festo’s Seamless Connectivity Part 1 – Products

December 15, 2021

By Krystie Johnston

These days, different standards are emerging at various levels of automation: products, communication protocols, safety standards, etc. Festo’s Automation Platform provides to the industry an adaptable, flexible, and convenient solution to gather huge amounts of different field devices, from servo drives to inductive sensors, by providing standards and protocols suitable for major PLC brands, allowing an easy integration and data gathering, ready for Industry 4.0. Presented at the German Technology Day 2021.

In Canada, Festo has been supporting Canadian industry for over 40 years, continuously elevating the state of manufacturing in this country with innovative products, optimized motion control solutions and unrivalled support. They have been engineering and introducing new electrical automation products, software, and services every year for a quarter of a century. “Seamless Connectivity” is their latest product and newest concept and will be the focus of this article.

What is ‘seamless connectivity’? Seamless, by definition, means, “smooth and continuous with no apparent gaps or spaces between one part to the next.” In terms of practicality or application, something that is seamless can be equated with convenience. Connectivity relates to connection or communication, and there are different types of connectivity. From Festo’s perspective, connectivity relates to connection or communication with FIELDBUS, cloud-based, or even digital technology. It is the ability to connect and communicate with multiple devices or peripherals.

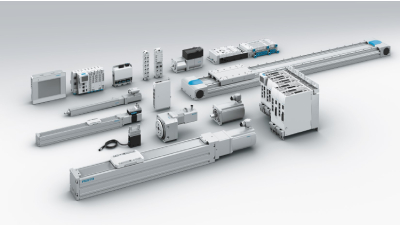

Festo’s latest products related to electrical automation consist of a program logic controller or PLC, a servo drive, and a distributed I/O or input/output device. Each are explained in detail below.

The CPX-E-CEC PLC is Festo’s high performance CPX-E automation system: a motion controller with comprehensive program logic control or PLC functionality and the ability to control multi-access applications with interpolated positioning. It has been designed for Industrie 4.0, and it includes cloud-based data sharing, open platform communication or OPC database integration, as well as FIELDBUS protocols, EtherCAT master or a BUS slave, Ethernet IP or Profinet.

The CMMT servo drives are Festo’s latest generation of servo amplifiers. They are compact point-to-point, multi-axis motion capable and suitable for various ethernet-based BUS networks. Designed for Industrie 4.0, it supports a multitude of FIELDBUS connectivity options. This drive can also share and transfer data over file transfer protocols or FTP and OPC servers and databases. The CMMT drive also supports Festo’s CDSB operator unit.

The CPX-AP-I distributed I/O FIELDBUS is basically designed for distributing input/output. The device is designed to support multiple electrical peripherals and pneumatic valve terminals over an I/O link master network. Currently capable of hosting up to 80 modules, it is undergoing development to support up to 500 modules in the future. Each block is IP65 or IP67 certified and allows users to decentralize communications. This device supports and helps lead the charge towards Festo’s concept of seamless connectivity.

Connectivity on a spectrum, in terms of products, can be seen as a range from difficult to easy. Products that are difficult to use require more time and expertise of the user, who needs to read manuals or seek technical support. As David Dolezal, Business Development Manager – Electric Automation points out, “Traditionally, I have to say that electric automation falls on the ‘difficult to use’ side of the spectrum. It does require a high level of expertise, especially if you aren’t familiar with that particular automation platform.” Products that are seamless, or almost seamless, on the other hand, are intuitive and easy to use. The goal is to make automation easy to touch and use in the same way that a smart phone or smart tv is intuitive without needing to read a manual before using it.

Festo strives to make automation more seamless by making products that are intuitive and easy to use. “That’s kind of our goal, and that’s where this campaign started. We’re not there yet, it’s definitely going to be a road to get there, but we’re working towards that concept, to eliminate doubt and confusion with regards to electric automation.”

Seamless connectivity can have multiple interpretations with respect to how Festo interacts with their customers and automation partners. This term sheds light on how companies connect to share ideas and turn them into working automation systems. In a similar way that machines connect with each other to communicate information, people can interact together with seamless connectivity to share ideas and communicate. “This part’s really cool because this is definitely one of the human aspects, not just about technology, but how we interact as a company.” These communication protocols will be discussed in Part 2 of this article, where the tools that Festo has developed to make the connection between user and equipment more seamless are explored in more detail.

Read Festo’s Seamless Connectivity Part 2 – Communication Protocols here

For more information visit Festo.ca