Endress+Hauser’s Partners in Process Food and Life Sciences Event 2022

August 17, 2022

By Krystie Johnston

The Endress+Hauser Canada’s Partners in Process Hybrid Event 2022 was a big success. For the first time, customers were able to experience the new Customer Experience Centre in Burlington, Ontario.

In early June, customers from the Food & Beverage and Life Sciences industries were welcomed into the Centre by Endress+Hauser staff, both in person and virtually. Mechatronics Canada had the opportunity to join them for this occasion and see firsthand what it was all about.

Welcome to Calibration

The event kicked off in the calibration lab, where Endress+Hauser discussed calibration in detail, and the various products and solutions they offer to support their customers. Mike Miller, Product Manager, Flow & Digital Business, Endress+Hauser Canada explained,

“Calibration is a comparison of a device to a known reference standard. Typically, we calibrate for a reason, such as quality control, compliance, or critical measuring points. Calibration is not necessarily everyone’s specialty – your specialty is producing your product.”

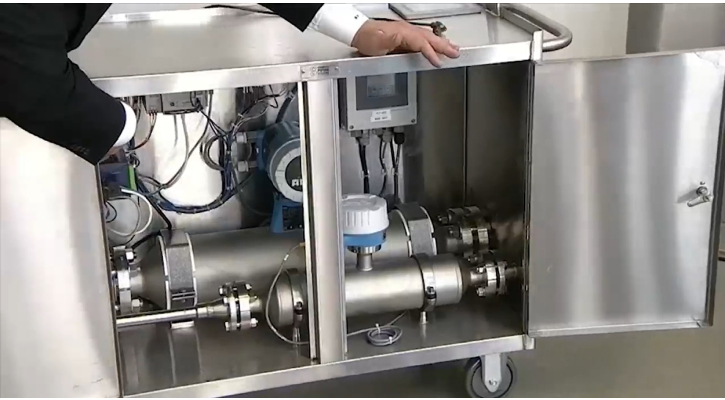

That is where Endress+Hauser comes in, to demystify this process and make it easy so that customers can spend more time doing what they do best. Martin Bedard, Calibration and Program Supervisor, at Endress+Hauser Canada, added that these solutions are expanded upon with a mobile solution. What customers see in the lab is available in mobile calibration services as well, which can be more efficient for the customer and can reduce downtime by performing calibrations on site. While demonstrating a flow calibration, Bedard explains,

“What you are looking at here is our larger pump module, or our in-house calibration pump. In Burlington, at our facility, we can do up to four-inch diameter flow meters on this flow lab; we use the same reference cart for the field, the only difference is the pump cart is slightly smaller to be able to access our customer’s sites.”

Endress+Hauser’s in-house calibration pump located in the full-service calibration laboratory

Endress+Hauser is known as “the flow meter company,” however, they can calibrate more than just flow. They can also calibrate pressure, temperature, pH, and conductivity and provide an accredited certificate for ISO 17025 for each one of these calibrations.

Solutions That Improve Quality and Reduce Operational Costs

Karina Ramirez, Food & Life Sciences Industry Manager introduced Doug Sitter, Client Manager of Actemium Toronto, and they discussed how Endress+Hauser can improve quality and reduce operational costs. With more than 20 years of automation experience in the Life Sciences and Food and Beverage Industries, Sitter shared some interesting applications that used Endress+Hauser products as a part of the solution.

He presented a Viscosity/Density/Flow/Temperature Test Cart they developed to allow Actemium’s customers to trial the Endress+Hauser Promass I 500 Coriolis mass flow meters in their process. “Try before you buy” has made it much easier for their customers to make decisions on these extremely accurate instruments. The cart also includes an HMI and PLC for local control and process integration and an Ewon Flexy for remote data monitoring and reporting.

Doug Sitter, Client Manager of Actemium Toronto, presenting the Viscosity/Density/Flow/Temperature Test Cart in the Endress+Hauser Process Training Unit

Another solution that Actemium presented was what they called a “Highly Reliable, Corrosive Resistant, Redundant Pump Lift Station.” These units were designed for clients that wanted to install production lines and didn’t want to cut into the building’s floor to add additional waste drains. “Building modifications cause production interruptions.” The units have stainless steel redundant submersible pumps, a control system with a UPS, a colour touch screen interface, a floor level waste inlet, and a waste outlet to allow pumping up to a waste header.

The original systems used conductivity sensors to detect waste level for pump operation, but one of their customers would flush their production lines with purified water (not detectable by the conductivity sensors), causing the systems to overflow. With the help of Endress+Hauser, vibronic point level detection (FTL51) was selected to replace the conductivity sensors. The system now functions without incident. As the product matured, Actemium added an additional sensor port to the pump system to allow for additional waste stream monitoring, and they offer Endress+Hauser sensor options for that.

These application examples demonstrate how Endress+Hauser’s products and solutions can be used to help improve customer’s processes efficiently. They also exemplify the partnerships they have across a range of industries and demonstrate their capabilities. To learn more about these solutions, or how Endress and Hauser can be a reliable partner for your application, visit their website https://www.ca.endress.com/en

Innovative Products Reduce Risks and Save Time Calibrating

Endress+Hauser introduced their innovative temperature offering. Tarang Patel, Product Manager Level, Temperature & Pressure and Florian Kuess, Applications Engineer, Temperature & System Products, discussed applications that rely heavily on specific temperatures in the Food & Beverage and Life Sciences Industries. Patel described how calibration of thermometers is crucial to ensure continuous product quality and safety, and how a drifted temperature measurement can damage the product and result in unpredictable consequences for the manufacturer. Patel and Kuess showed how two major innovations from Endress+Hauser can improve manual calibration and even achieve continuous monitoring of a possible drift.

The iTherm QuickNeck

iTherm QuickNeck can help save time during the calibration process as the temperature insert can be removed with one simple twist for dismounting and easy re-installation. It can also eliminate the risk of damage caused during calibration, the risk of lost parts or water ingress, resulting in costs savings and less downtime.

In this video, Kuess demonstrates the iTHERM QuickNeck

{videobox}pFNLToGycuU{/videobox}

Another product was developed to solve for the problem of what to do when a deviation is detected after a calibration was done. A solution that ensures compliance with temperature that the customer can use more frequently, even daily, reduces the risks and costs associated with long-term deviations. Using an example of 6-month intervals between manual calibrations, it is critical to investigate and determine when the deviation began.

The iTherm TrustSens

iTherm TrustSens is a device that took more than ten years to perfect. It launched in the European market in 2017 and then in North America in 2018. Kuess says, “It is the first world-wide self-calibrating thermometer.” The TrustSens is a Pt100 sensor that is attached directly to a highly accurate fixed-point reference element, which is a special ceramic that uses the Curie temperature effect to generate a reliable calibration signal.

It can minimize risk and measurement uncertainties in critical processes as it performs regular self-calibration at the specific curie temperature in common applications like UHT in dairies or during SIP cycle in autoclaves.

Customers Experience the Process Training Unit

Brad Iles, Training & Development Manager, walked customers around the top of the PTU and demonstrated the Coriolis flowmeter Promass Q, the highest measurement accuracy for mass flow, volume flow and density. Being the preferred choice for custody transfer applications, it has also been optimized for liquid applications where entrained gas is known to be present. Iles replicated the presence of air in the pipe as one of the challenges that occur in real process facilities, like for example, milk receivers, and the ways that they can troubleshoot these issues.

The the PTU has a lot to offer. Iles explains,

“It is a mini, running process plant. It allows us to do demos and training for our internal people, our partners, and our customers. We have different Endress+Hauser devices for flow, pressure, temperature, level, and liquid analysis, so we show customers how they work in a real running process plant, for the purpose of showing how to install and commission them. We can also create some process “troubles” to discuss troubleshooting, and how we can make the products work best for your applications.”

Brad Iles, Training & Development Manager, Endress+Hauser, demonstrates the Coriolis flowmeter Promass Q

As a mini processing plant, the PTU consist of several different tanks in different styles: for instance, a conical-bottomed tank, a hygienic tank with an agitator, and another that is horizontal. There are flow loops and other devices that replicate an actual process plant. Customers can use these instruments and talk to Endress+Hauser employees to trouble-shoot problems that may be occurring in their facilities to gain experience and knowledge, and find the right products and solutions tailored to their application.

Alliance Partners

Customers were also shown the Plant PAX offering from Rockwell Automation, an alliance partner with Endress+Hauser. Their process offering allows Endress+Hauser to integrate their devices into the Rockwell system, which gives Rockwell the ability to control the system through the control room. Pamela Blais, Technical Consultant Rockwell Automation, explains the system on the screen,

“You are going to have things like tanks, valves, flow control, all set up within your system. You might have pumps that are operating in there, and all of these will have faceplates that are part of the Rockwell process library – this will save time for the integrators or OEMs that are developing these systems.”

Attendees online and in person were also able to have a closer look at the Viscosity/Density/Flow/temperature Test Cart and ask questions to Sitter. They were able to have a hands-on experience with the innovative temperature offerings that were presented earlier, such as the iTherm QuickNeck. The PTU and its hardware and sotware were also avaialble for customers to experience.

Conclusion

The event showcased how Endress+Hauser is a reliable partner for their customers in the Food & Beverage and Life Sciences industries. The staff were down to earth and knowledgeable about their products and services, and encouraged attendees to ask questions throughout the tour. To learn more about the event, register here to view the session recordings.

Visit endress+hauser.ca for more details