Celebrating 50 Years of Customer-Inspired Innovation

October 25, 2023

Celebrating 50 Years of Customer-Inspired Innovation: ABB Measurement and Analytics’ Quebec factory marks half a century of advanced analytical solutions

The early days

The Quebec factory of ABB Process Automation – Measurement and Analytics is one of the major players in the industrial analytical measurement field and the largest Canadian supplier of space-based optical sensors. But fifty years ago, it started out as a small local business, Bomem Inc., that grew over five decades into one of the flagship companies of Quebec City’s high-tech industry.

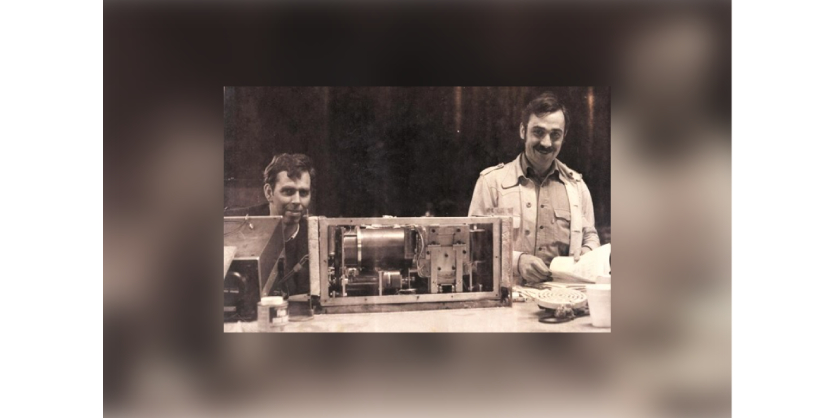

Founded in 1973 by Dr. Henry Buijs, Garry Vail, and Jean-Noel Bérubé, Bomem Inc. initially focused on revolutionizing the field of spectroscopy. Their vision was to pioneer advancements in the field and provide cutting-edge solutions for analyzing molecular compositions and structures.

In the 1970s, Henry Buijs was one of the first physics engineers to develop the technology for measuring the precise state of the ozone layer. He made an outstanding contribution to the field of infrared spectroscopy and to the design of analytical techniques using this technology, which was at the core of this company’s creation.

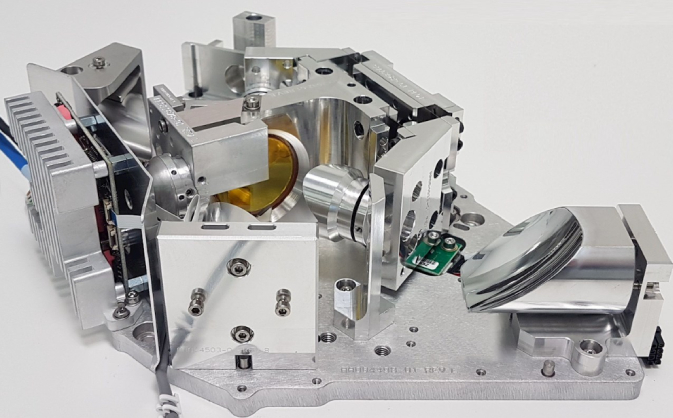

Bomem Inc. quickly made a name for itself by specializing in Fourier Transform Infrared (FTIR) spectroscopy, a powerful analytical technique with applications in various industries, including pharmaceuticals, oil and gas, environmental monitoring, chemicals, semiconductors, and more.

Evolution and expertise

In 1999, Bomem Inc. reached a pivotal moment in its history when it was acquired by ABB, a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. This acquisition marked a new era for the company, allowing it to harness ABB’s extensive resources and reach to further enhance its offerings and impact on the global stage.

Fifty years after its inception, there are over 400 employees at the Quebec City site. The company stands out as a leading entity in the optics-photonics industry and has become synonymous with innovation and excellence, particularly in the realm of analytical solutions for Quality Assurance and Quality Control (QA/QC) applications and process monitoring.

The biggest R&D group of ABB Measurement and Analytics is in the Quebec factory in Canada, showcasing their commitment to consistent innovation. The group consists of 150 engineers and scientists, each with their own expertise in various domains such as research and development, manufacturing engineering, sales support, and after-sales service.

Diversification

Drawing from a foundation of innovative engineering and manufacturing, rooted in its spectroscopy origins, the business unit has dynamically expanded its product portfolio. While maintaining its focus on spectroscopy, the company diversified its offerings to include a range of cutting-edge instruments and analyzers in various applications addressing several industries’ measurement needs. Through this strategic diversification of its product lines, ABB’s continuous evolution of its offering ensures that industries relying on accurate analysis and measurement have access to state-of-the-art solutions, ultimately contributing to enhanced efficiency, safety, and sustainability across diverse sectors.

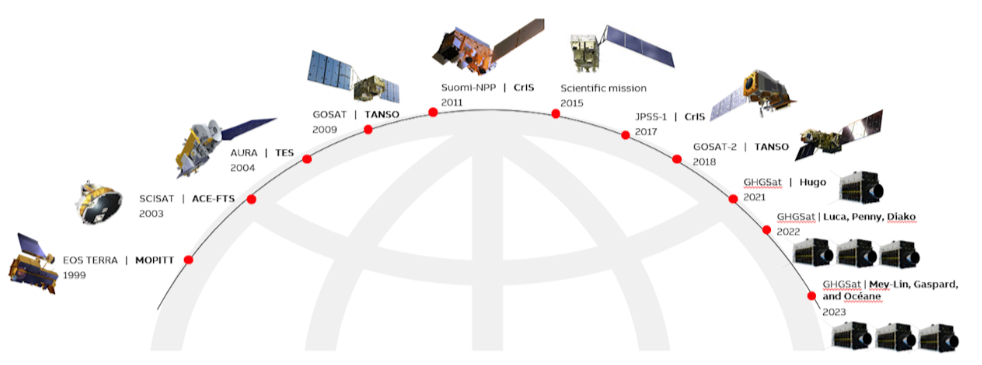

A legacy of space heritage

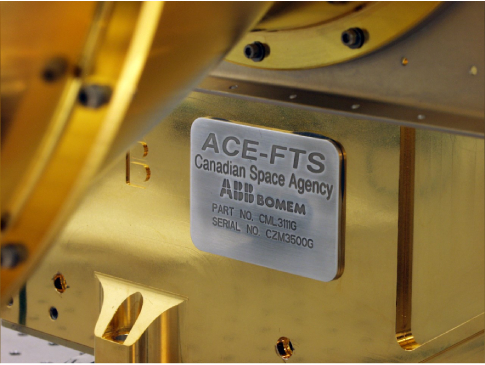

The ABB Quebec factory has been providing solutions to meet the needs of customers in the global space industry since 1973, collaborating with major space agencies worldwide and offering services such as weather forecasting, climate analysis, earth observation, space exploration, and astronomy.

The unique combination of its facility installations and volume manufacturing capabilities allows ABB to support its customers’ missions in a variety of ways, from feasibility studies to the production of complete optical payloads and other mission-critical instrument modules.

Moreover, today ABB is focused on the privatization of Earth observation missions, known as Space 2.0. The company is applying its expertise in this field to strategically modernize the area and continue to make advancements in the space industry.

A promising and sustainable future

Today, Bomem Inc.’s legacy lives on as part of ABB Measurement and Analytics, where their contributions to spectroscopy technology endure, leaving an indelible mark on scientific progress and industrial applications worldwide.

As the company moves into its next half century, the ABB Quebec factory has showcased its high level of resilience, and ability to adapt and innovate remaining at the forefront of technological advancements in analytical measurement.

“Listening to the customer is key for innovation and is the basis of our foundation. It makes our company ready to focus on the next chapter of our history and pursue the unprecedented growth delivered in the last decade,” said Marc Corriveau, Head of Global Operations, Analytical Business Line, ABB

“The future is bright for ABB Measurement and Analytics Quebec factory. “Getting where we are today would not have been possible without multiple generations of talented employees. I am grateful for their extraordinary contribution,” he concluded.

Officially, the Quebec factory of ABB Measurement and Analytics celebrated its 50-year anniversary on September 21, 2023.

More Information

Related Story

ABB To Push Boundaries of Methane Emissions Monitoring with Funding from U.S. Department of Energy

ABB has received significant funding from the U.S. Department of Energy (DOE) Office of Fossil Energy and Carbon Management and the National Energy Technology Laboratory (NETL) to design an Integrated Methane Monitoring Platform that will advance the development of new and innovative methane measurement, monitoring and mitigation technologies in the United States. The total value of the project is $1 million, of which DOE will contribute 80 percent, with ABB contributing the remaining 20 percent.