ABB Predicts Key Trends That Will Change Robotic Automation in 2022

May 5, 2022

With demand for robots growing as companies in multiple sectors look for new ways to enhance their productivity and competitiveness post-pandemic, ABB has compiled a set of growth predictions, looking at key trends driving demand for robots in the coming year.

“The pandemic accelerated far-reaching global mega trends – from labor shortages and supply chain uncertainty, to the individualized consumer and growing pressure to operate sustainably and resiliently – leading new businesses to look to robotic automation,” says Marc Segura, ABB’s newly appointed Robotics Division President.

“As technology opens new opportunities for meeting customer demands, new trends will continue to emerge that will further drive demand in areas where robots have traditionally not been used.”

Based on customer conversations, market research and a global survey of 250 companies across multiple industries, ABB has identified three key trends that will shape the demand for robots in 2022.

Trend 1 – The EV revolution is bringing wholesale changes for automotive manufacturing

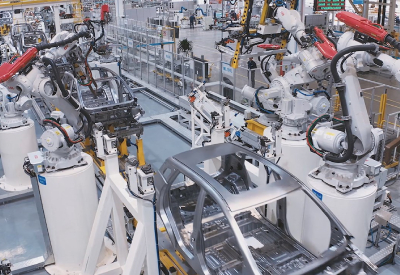

With many countries restricting and phasing out the production of combustion engine vehicles over the next decade, the race towards electric cars has accelerated. Manufacturers and their supply chains must tackle the complexity of diversifying into EVs alongside combustion-engine vehicles, to meet varying regulatory frameworks governing EV adoption across the globe. The speed and added flexibility needed will see new and established manufacturers move away from traditional linear manufacturing, towards modular, flexible production.

Segura said:

“EV is not about a change only in the powertrain, but a larger transformation to a digitized car. This transition will also see the growing uptake of robots in combination with other technologies, including Autonomous Mobile Robots (AMR’s). This will enable manufacturers to optimize the delivery of components across facilities and enable integrated scalable, modular production cells – methods traditionally associated with e-commerce and consumer goods, but now required in automotive to ensure the necessary flexibility to meet varying levels of demand.”

Another major shift will see battery manufacturing brought closer to vehicle assembly, to meet sustainability and regional requirements, which in most cases requires all-new facilities.

Trend 2 – The E-commerce boom will accelerate

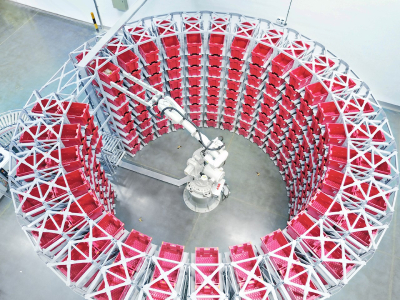

Consumer behavior and expectations are driving companies to find new ways to satisfy demand, developing new channels through omnichannel retailing and adapting their production lines and distribution processes to enable personalization of both products and delivery. Fulfilling these requirements has seen thousands of robots installed worldwide where they were not used just five years ago, and this rapid rate of automation will continue in 2022 driven by a combination of consumer trends and a growing shortage of labor.

“This trend will see the growth of lighter, smaller robotic applications, enabling the expansion of automation into new areas of warehousing and distribution operations. As Artificial Intelligence in robotics matures and learning robots become mainstream, expect to see these technologies deployed alongside AMR technologies, orchestrated and managed by intelligent software to provide enhanced flexibility, speed and efficiency,” Segura continued.

Trend 3 – More robots will appear in more places – and workers will need new skills

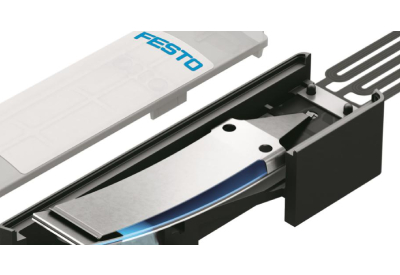

Smaller, more affordable, and easy-to-use robots, such as ABB’s YuMi®, GoFa™ and SWIFTI™ cobots, are helping to remove many of the barriers previously preventing companies from investing in robots. This is seeing an acceleration of robots in general industry and small and medium-sized enterprises as companies seek new ways to automate different tasks.

Segura continued:

“As we look beyond 2022, we see an ever-greater emphasis on connectivity and data acquisition as key enablers of future manufacturing. Data collected from intelligently automated processes will be analyzed by producers to make more informed decisions. At the same time, more advanced and responsive simulation, and programming software tools, such as those in ABB’s RobotStudio®, will cover the entire life cycle of robotic applications – from commissioning to onstream productivity – using AR and VR tools to simplify automation for customers.”

The enhanced ability of robots to work directly alongside humans, share tasks and learn through AI is also making it easier for companies to adopt intelligent automation in new environments, such as construction, healthcare laboratories and restaurants and retail.

In a future with a high prevalence of robots in workplaces, engineers and staff will need to be retrained and more robotic training will be demanded in schools, colleges, and universities, for the skills to program, operate and maintain robots for an automated future.

A decade of change

The trends outlined for 2022 are the latest chapter in the ongoing transformation of robotic automation which is seeing a rapid acceleration and adoption of robots across industry.

“While automation has always been about productivity and quality – scaling up, doing more – the shifts we’re witnessing today (the greatest in a generation) mean that flexibility and simplicity are key to success,” concludes Marc Segura. “Today, flexibility is essential – it is a strategic need, essential across the entire value chain: from manufacturing and logistics through to the point of consumption. Robotic automation is a vital enabler of this flexibility.

“ABB’s goal is to help our customers achieve this flexibility and add value to their businesses by driving innovation to create new possibilities with robotics, mobile robotics and machine automation, supported by the digital services and training they need to get the most from their investment.”