Mitsubishi Electric Automation, Inc. Announces Release of MELSOFT Gemini 3D Simulator Software

January 31, 2023

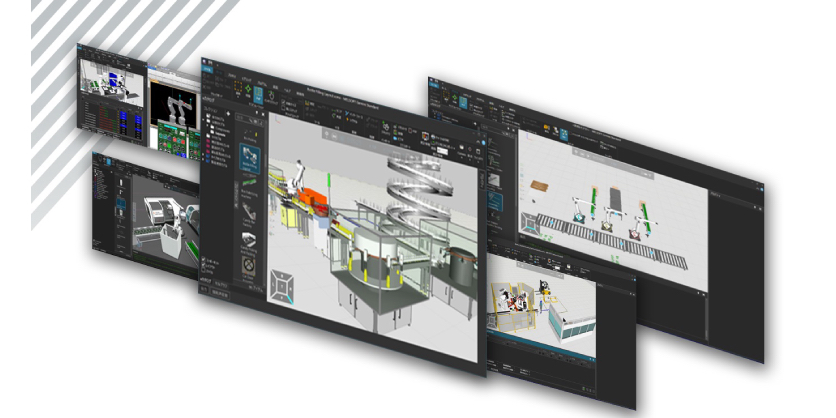

‘Gemini’ models machines and manufacturing processes virtually, to allow users to visualize their manufacturing projects and reduce risk by validating designs in advance

Mitsubishi Electric Automation, Inc. has released its MELSOFT Gemini 3D Simulator Software to allow users to expedite the design and construction of manufacturing projects as they introduce new automation components to their facility. By connecting to a variety of software and factory devices, Gemini provides visualization, simulation, and the streamlining of work processes.

Gemini operates using a PC-based 3D digital space and connects directly to factory devices without having to go through an OPC server. This enables 3D data to be updated in digital spaces approximately 12 times faster than OPC environments. As engineers use the software for their verification purposes, they can test and debug the automation logic for machines and systems, as well as check the operation of the planned production facility prior to construction.

As their projects advance into operation and maintenance phases, engineers can quickly identify the causes of abnormal occurrences in their production line using logged data to step through and review the error event on the synchronized 3D model, PLC sequence monitor, waveform display, and/or video data.

Gemini includes a hardware menu that offers selection from approximately 2,500 types of production equipment, including robots, conveyors, processing machines, and more. These can be combined in a simulated 3D production facility via easy drag and drop operation. Users can also set parameters to adjust the way the virtual production line operates.

“The manufacturing sector is seeing an increase in demand for digital transformation within factories. Software assets like 3D simulators are a pivotal part of this transformation.”

Lee Cheung, associate product manager at Mitsubishi Electric Automation

More Information

Related Story

Mitsubishi Electric’s Factory Automation Systems Business to Launch “Automating the World” as Global Slogan

Mitsubishi Electric Corporation recently announced that it will launch “Automating the World” as the global slogan for its Factory Automation Systems business. Commercial use of the slogan began worldwide on November 8, 2022.

The new slogan expresses Mitsubishi Electric’s goal to leverage automation for the betterment of global society by combining advanced technology, experience and know-how, and customer support as a trusted partner.