Weidmüller Ltd. Signs a Distribution Partnership with Shelley Automation

Shelley Automation will market Weidmüller’s complete portfolio in the Ontario region. That includes I/O systems, industrial Ethernet, relay modules, and power management, to name a few

May 17, 2022

Weidmüller Ltd. has signed a distribution partnership with Shelley Automation for the Ontario region in Canada. It is part of the growth strategy embarked on by Weidmüller Ltd. under the new leadership of Michael Daly, Managing Director.

Shelley Automation will market Weidmüller’s complete portfolio in the Ontario region. That includes I/O systems, industrial ethernet, relay modules, and power management, to name a few.

Shelley Automation is a known name within the industry for automation solutions and more and has been serving since 1959. They have built strong partnerships with their customer base and delivered cutting-edge solutions through time.

Michael Daly commented on the collaboration, “With Shelley Automation’s integration, Weidmüller’s distribution network looks more robust than ever. In addition, Shelley has a good team of professionals who know their trade, and we are confident of this alliance.”

Michael Daly, Managing Director

Selman Qadri, Director of Sales and Marketing, said, “This is an exciting time for Shelley. We believe there is good synergy between Weidmüller products and our expertise in automation. We can confidently go to market with Weidmüller products because they are an established brand and have quality products that address many industry problems.”

Selman Qadri, Director of Sales and Marketing

Related Product

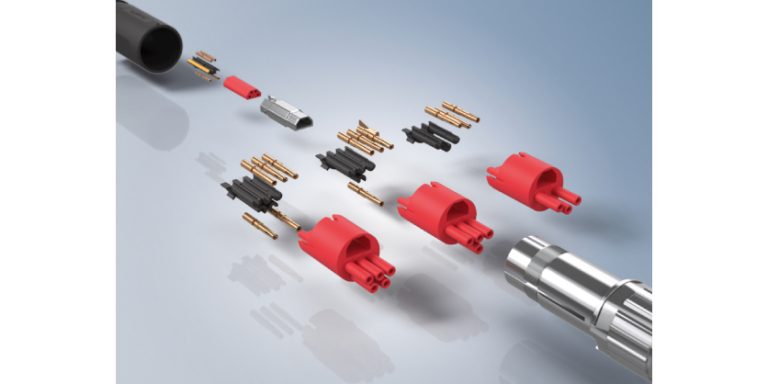

PROtop from Weidmuller – the Powerboost for Your Production Environment

Powerful, efficient, and sustainable. PROtop combines highest efficiency and compact housings with high durability and direct parallel connection without diode modules. This reduces costs and creates space in the cabinet. Due to the powerful DCL technology, even difficult loads – motors, for instance – are operated smoothly, while circuit breakers are triggered reliably. The good communication capability allows permanent condition monitoring and full integration with control systems.