Waterloo Wins Backing for Training in 2D Materials

June 16, 2022

Recently, a key puzzle piece fell into place with the announcement of $1.65 million in federal funding for a joint training program involving the University of Waterloo and partners in Germany. Support from the Natural Sciences and Engineering Research Council of Canada (NSERC) gives the green light to a nine-year initiative to train dozens of graduate students and help bring promising new two-dimensional materials out of the laboratory and into the marketplace.

Five years in the making, the collaboration involves experts at the University of Duisburg-Essen, RWTH Aachen University and eight engineering and chemistry professors at Waterloo in a project dubbed 2D-MATURE.

Through workshops, international exchanges and industry partnerships, the objective is to provide almost five dozen graduate students in Canada, and a similar number in Germany, with the know-how to scale up the production of 2D materials and make them commercially viable.

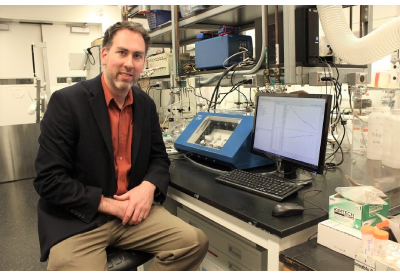

“We have found, I think, that perfect collaborative fit – and it’s the right time,” said Michael Pope, a chemical engineering professor who is leading the initiative for Waterloo. “We’re at the right research-versus-commercialization phase in 2D materials development.”

Two-dimensional materials such as graphene – the first one to be discovered by Nobel Prize-winning researchers – can be made as thin as a single layer of atoms.

That gives them special properties, such as extremely high surface area, and a wide range of potential uses including in transistors for high-speed computers, smaller, lighter, longer-lasting batteries, and composite tennis racquets.

‘A little goes a long way’

“A little bit goes a long way,” Pope said of the early tennis racquet application. “Essentially, you can replace other materials that were used for strengthening with a much smaller amount and get higher performance.”

Engineers and scientists around the world are now searching for other materials that can be fabricated in 2D – there are believed to be about 2,000 of them – and developing ways to economically produce them in sufficient quantities for commercialization.

Students in the 2D-MATURE program will also learn about business-related subjects such as intellectual property laws, and the impact of mining for precursor materials on Indigenous people in areas including Northern Ontario and Quebec.

With cash and in-kind support from the University of Waterloo, funding for the Canadian researchers is over $4 million. The federal support was awarded through NSERC’s Collaborative Research and Training Experience (CREATE) program.

‘We’re hoping to bridge that gap’

The other professors involved at Waterloo are Zhongwei Chen in chemical engineering, Na Young Kim and Irene Goldthorpe in electrical and computer engineering, Kyle Daun and Kevin Musselman in mechanical and mechatronics engineering, and German Sciaini and Rodney Smith in chemistry.

Pope said researchers at Waterloo and Duisburg-Essen have complementary expertise, and both schools feature established nanotechnology institutes. The idea for the project began taking shape at a workshop hosted by the Waterloo Institute for Nanotechnology about five years ago.

“It’s going to be a lot of work, but it’s going to be a lot of fun as well, and it will really elevate my research program and those of my colleagues here,” said Pope, who is seeking applications from graduate students interested in the specialized program.

“It’s difficult to go from the lab to commercialization because there are so many nuances along the way that must be understood as you scale up. We’re hoping to bridge that gap between research and the commercial use of 2D materials.”