Stepper and Servo Motor Control Technology Training Packages

February 9, 2024

Stepper and servo motors are essential for precise and controlled motion. They enable automation, accuracy, and efficiency in a wide variety of industrial applications for increased productivity and competitiveness.

However, their complexity stems from intricate control systems, demanding a nuanced grasp of electrical engineering, precise programming skills, and the ability to navigate the interplay between mechanical components and electronic controls for optimal performance in various applications.

Automation, robotics, and mechatronics specialists, as well as industrial electricians, and electrical and maintenance technicians are responsible for the installation, commissioning, maintenance, and troubleshooting of stepper and servo motors.

Festo Diadactic’s new compact learning solutions offer a controlled, safe, and tailored environment for learners to develop these foundational skills, with a focus on position, speed, and torque control, before engaging with more complex, real-world applications.

Highlights

- Comprehensive, turnkey course material on Festo LX

- Focus on troubleshooting and diagnosis

- Modern, industrial components from Festo

- Linear- and angular-axis, and gantry applications

- A single controller for both motors

- Free, professional configuration software

- Compact and safe work environment

- Flexible packages to accommodate various needs

Build practical skills that can be applied quickly in the workplace

What learners can study:

- Stepper and/or servo motor working principles, construction, and applications

- Torque calculations and motor selection for specific tasks

- Drive configuration and commissioning

- Diagnostics and troubleshooting techniques

- Wiring and manual motor operation

- Homing and motion trajectories

- Power transmission methods for angular and linear motion

- Open- and closed-loop control using encoders and feedback devices

- PID control for position, speed, and torque

- Control strategies using a PLC

- Control and coordination of multiple axes independently

- And more

The courses: The foundation of the learning experience

The courses guide learners step-by-step throughout the learning exercises.

Theory is introduced in a straightforward way. Pedagogical objectives are aligned to professional requirements. A project provides an opportunity for the consolidation of knowledge and skills, for an engaging learning experience.

Instructors benefit from the turnkey and comprehensive nature of the curriculum, which saves them time and energy

- Multimedia integration (animations, videos, pictures…) for enhanced learning

- Development of transversal skills (problem-solving, critical thinking, communication…)

- Courses available as a digital courses in our portal Festo LX or as PDF workbooks.

Three training packages are available, each accompanied by its own dedicated course

Instructors can select the course to cover either servo or stepper motors, or both. Each course corresponds to a training package that contains all necessary equipment to perform the learning activities.

- TP 1423 Servo and Stepper Motor Control Technology (course on Festo LX)

- TP 1422 Stepper Motor Control Technology (course on Festo LX)

- TP 1421 Servo Motor Control Technology (course on Festo LX)

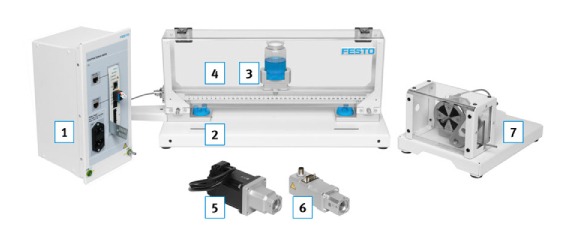

A look at the training package “Stepper and servo motor control technology TP 1423”

[1] Stepper/servo controller (with the CMMT-ST Servo Drive) that can be configured and diagnosed with the free professional Festo Automation Suite

[2] Linear application (with the ELGC-BS Ball Screw Linear Actuator)

[3] Accessory on the carriage block that helps visualize the effects of oscillation and vibration during travel along a linear axis

[4] Protective guards that prevent contact with moving parts

[5] Servo motor

[6] Stepper motor (EMMS-ST)

[7] Angular application, with a magnetic brake that can be used to apply a load during speed control experiments

Optional components, such as a gantry application update kit, are available.

More Information

Do you want more information or a personalized quote? Contact Festo today

Related Story

Festo Didactic at the Forefront of Developing Canada’s Future Work Force

With Canadian manufacturing suffering from a growing labour shortage, the participation of industry in skills development is emerging as a vital component in hiring and retention. The needs are stark: The Canadian Exporters and Manufacturers Association says almost 40% of its members have jobs they can’t fill. Five years from now, 60% expect to be short-staffed, especially when it comes to skilled trades. Statistics Canada forecasts the country’s labour force growth rate will remain below 0.2% for the rest of the decade, below replacement levels.