Stepper and Servo Motor Control Technology Training Packages

February 29, 2024

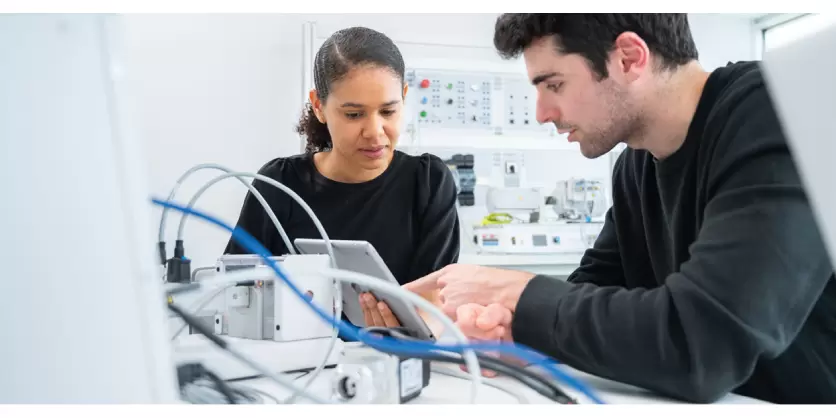

Teach the fundamentals of stepper and servo motor control technology; position, torque, and speed control to future and current mechatronics and robotics specialists, industrial electricians, and maintenance technicians. Build practical skills that can be applied quickly in the workplace, with the latest technology from Festo. Turnkey courses and training equipment cover motor installation, commissioning, maintenance, and troubleshooting, and more.

Overview of practical exercises of the stepper and servo motor training kit: Exercise 1: Drive configuration and manual control (angular axis) Exercise 2: Position control open loop on an angular axis Exercise 3: Position control closed loop on an angular axis Exercise 4: Speed control on an angular axis Exercise 5: Torque control on a linear axis Exercise 6: Position control in linear axis Exercise 7: Communication and control with a PLC Exercise 8: Project: interpolated axes on two linear axes

More Information

Stepper and Servo Motor Control Technology

Related Story

Stepper and Servo Motor Control Technology Training Packages

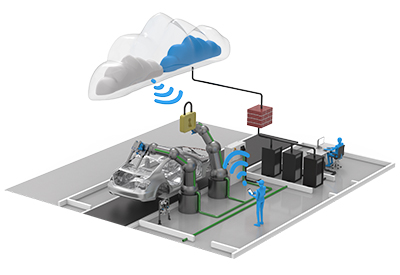

Stepper and servo motors are essential for precise and controlled motion. They enable automation, accuracy, and efficiency in a wide variety of industrial applications for increased productivity and competitiveness.

However, their complexity stems from intricate control systems, demanding a nuanced grasp of electrical engineering, precise programming skills, and the ability to navigate the interplay between mechanical components and electronic controls for optimal performance in various applications.

Festo Diadactic’s new compact learning solutions offer a controlled, safe, and tailored environment for learners to develop these foundational skills, with a focus on position, speed, and torque control, before engaging with more complex, real-world applications.