SCHUNK Shows That There Is a Lot Going On

October 27, 2021

SCHUNK at the SPS 2021, November 23-25: Hall 3A, Booth 111

Consulting visitors of SCHUNK’s show booth online directly from the Robot Application Center of their Hausen location – everything is possible these days. SCHUNK will give a foretaste at this year’s SPS from November 23 to 25, 2021 in Nuremberg. Customers will experience various solutions for smart and intelligent automation processes at the multimedia booth. Application experts will guide you through various fields of application in a personal technical exchange or a direct live connection to SCHUNK.

There is a lot going on in the development of automation technology – not least thanks to SCHUNK. The technology developer of gripping systems and clamping technology with decades of application knowledge knows both the needs and expectations of the market and of customers and partners. Together, there are new possibilities for optimizing production processes with innovative products, modern technologies, and adapted services. Regardless of whether it’s about taking the first steps into automation or scrutinizing already established production processes – SCHUNK meets the challenges and is opening up new automation paths for a wide variety of industries.

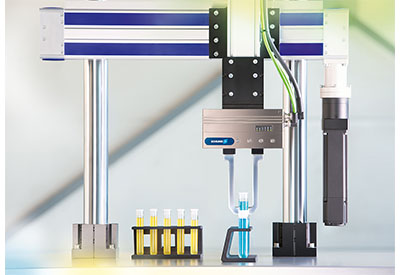

This is also reflected in the expanded interactive booth concept at the SPS, the trade show for smart and digital automation. At SCHUNK, trade visitors will experience examples of solutions for the versatile spectrum of automated manufacturing, such as the delicate gripping of sensitive components, electrical assembly automation or exciting practical examples from life science industries. At various stations, visitors can exchange information directly online with the SCHUNK experts in the CoLab Robot Application Center, regarding exciting gripping concepts such as the bionically inspired ADHESO gripper technology or magnetic gripping with cobots.

In addition, the application engineers will showcase live how deburring, grinding or polishing processes can easily be converted from manual to automated with the new SCHUNK tools. Anyone, who wants to take a look behind the scenes at SCHUNK, can get an exclusive insight on the virtual tour of the SCHUNK manufacturing facility at the SPS.