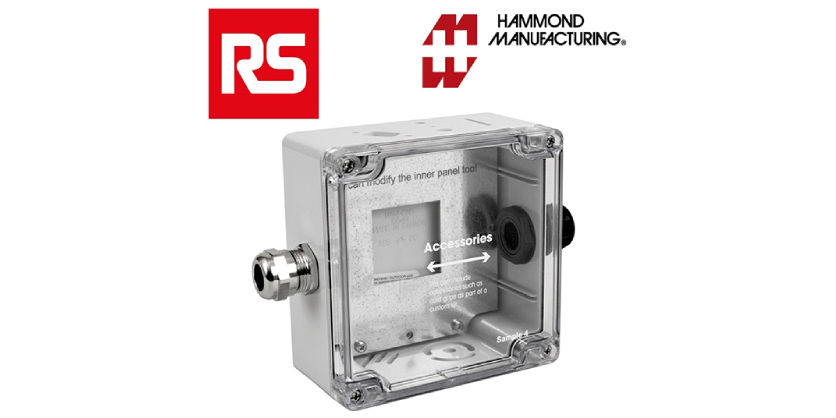

RS Partners With Hammond Manufacturing to Provide Custom Electrical and Electronic Enclosures

June 5, 2023

RS Group plc offers more than 4,900 fully customizable electrical and electronic enclosures from Hammond Manufacturing, in addition to more than 2,900 supporting products.

Enclosures are used to connect and protect two or more electrical and electronic components and devices. They are employed in virtually every commercial and industrial application, and every enclosure gets modified in some way. The simplest enclosures, junction boxes, have just a couple of holes cut for input and output wires, while more complex enclosures can have holes cut for connectors, displays, and other components and can even be silkscreened, molded in a special color, and fabricated to a special size.

Hammond Manufacturing can factory modify every one of the more than 2,100 electrical enclosures and more than 2,700 electronic enclosures that RS has in stock or available for drop-shipping during the order fulfillment process and is committed to delivering a perfect product. Most modifications can be completed in just a few weeks.

During that time, Hammond will submit a custom drawing for approval, machine the approved design, and overnight ship a sample enclosure so customers can test it with their components and devices. Then, it will make any additional modifications necessary to ensure that it’s perfect before shipping the final product to customers with a custom part number that they can use if they ever want to order that same enclosure through RS again.

“Our factory modification process is a real differentiator,” said Tom Ballou, the Sales and Marketing Manager at Hammond Manufacturing. “More than half the time, after a customer receives a sample of the custom design they’ve already signed off on, they come back and ask for a small change. It’s almost never a mistake; it’s usually just something they noticed would be perfect if it were just a little bit different, like moving a hole five-thousandths of an inch, and our process allows us to make it perfect for them.”

Tom Ballou, the Sales and Marketing Manager at Hammond Manufacturing

A Brief Look: Hammond Manufacturing

Hammond Manufacturing has over 100 years of experience designing, manufacturing, and modifying a wide variety of electrical and electronic enclosures and offers more than 13,000 enclosures and related products — including power distribution equipment, thermal management solutions, transformers, tools & hardware, wire & cable products, and rack mounting solutions — through RS to provide customers with a convenient source for complete custom solutions. Its electrical enclosure line includes mild steel, stainless steel, aluminum, non-metallic, disconnect, modular freestanding, operator interface, and commercial enclosures, as well as wireway and trough, climate control solutions, rack mounting solutions, and accessories extending from hardware, panels, and panel accessories to outlet strips, window kits, and lighting.

Its electronic enclosure line includes diecast, plastic, extruded, general-purpose metal, chassis, rack-mounted, and industrial enclosures, as well as development board products, handles, and accessories extending from feet, hole plugs, and cord grips to tilt bails and pole mounting kits.

“RS is a great source for factory modified enclosures,” said Tom. “Although Hammond is a leading global supplier of electrical and electronic enclosures, it’s also a family company with about 1,000 employees, so our partnership with RS is really valuable. The RS sales team is unique in how knowledgeable and well experienced they are when it comes to Hammond enclosures. Selling custom, modified enclosures requires a real hands-on relationship, and RS works closely with customers to get a comprehensive understanding of their application and help them select the best modifications for their needs. We’ve had a lot of success together so far and are looking forward to a lot more.”

Tom Ballou, the Sales and Marketing Manager at Hammond Manufacturing

The extensive amount of inventory available through RS and its partnership with Hammond Manufacturing helps customers reduce inventory, avoid expedited orders, and prevent project delays, and Hammond’s unique factory modification process ensures that every enclosure is a perfect enclosure for the application at hand.

Related Product

Hammond Manufacturing: Type 1 Galvanized Lay-In Wireway CWG Series

Introducing the CWG Series Type 1 Galvanized Lay-In Wireway from Hammond Manufacturing, with a construction designed to ensure electrical continuity and to permit fast and easy indoor installation of multiple wireway runs. These runways, formed from 16 or 14 gauge, unpainted G90 galvanized steel, have UL-50 Type 1 and cUL Type 1 standards.