Rising Demand for SiC Chips: Bosch Plans to Acquire U.S. Chipmaker TSI Semiconductors

Plans to invest 1.5 billion USD in strategically important semiconductor business for electromobility

May 25, 2023

- Bosch chairman Dr. Stefan Hartung: “With this planned investment in the U.S., we are also increasing our semiconductor manufacturing, globally.”

- Third pillar for semiconductor business: following Reutlingen and Dresden in Germany, Bosch will in the future also make chips in Roseville, California.

- More chips: with the planned acquisition, Bosch will significantly expand its global portfolio of SiC semiconductors by the end of 2030.

- Electric cars as the driving force: SiC chips enable greater range and more efficient recharging.

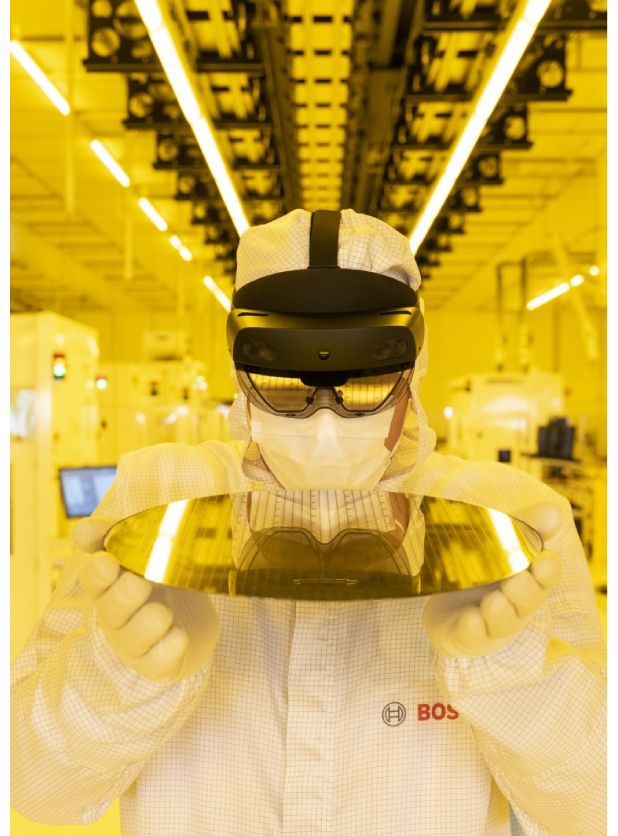

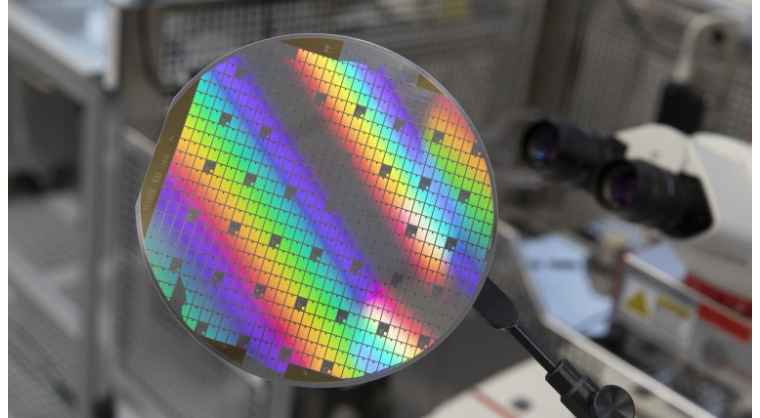

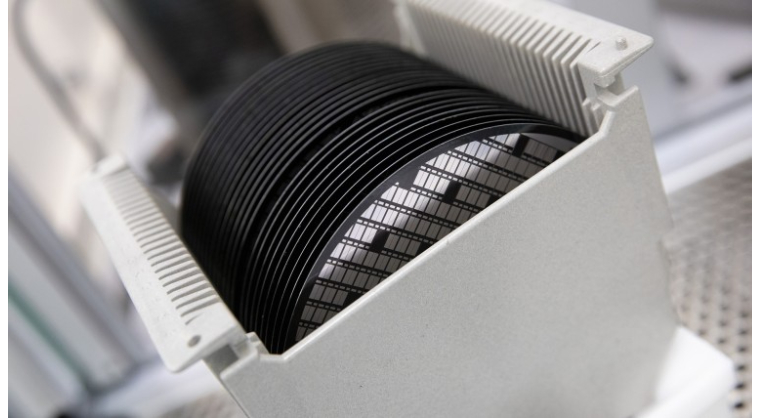

Bosch is expanding its semiconductor business with silicon carbide chips. The technology company plans to acquire assets of the U.S. chipmaker TSI Semiconductors, based in Roseville, California. With a workforce of 250, the company is a foundry for application-specific integrated circuits, or ASICs. Currently, it mainly develops and produces large volumes of chips on 200-millimeter silicon wafers for applications in the mobility, telecommunications, energy, and life sciences industries. Over the next years, Bosch intends to invest more than 1.5 billion USD in the Roseville site and convert the TSI Semiconductors manufacturing facilities to state-of-the-art processes. Starting in 2026, the first chips will be produced on 200-millimeter wafers based on the innovative material silicon carbide (SiC).

In this way, Bosch is systematically reinforcing its semiconductor business, and will have significantly extended its global portfolio of SiC chips by the end of 2030. Above all, the global boom and ramp-up of electromobility are resulting in huge demand for such special semiconductors. The full scope of the planned investment will be heavily dependent on federal funding opportunities available via the CHIPS and Science Act as well as economic development opportunities within the State of California. Bosch and TSI Semiconductors have reached an agreement to not to disclose any financial details of the transaction, which is subject to regulatory approval.

“With the acquisition of TSI Semiconductors, we are establishing manufacturing capacity for SiC chips in an important sales market while also increasing our semiconductor manufacturing, globally. The existing clean-room facilities and expert personnel in Roseville will allow us to manufacture SiC chips for electromobility on an even larger scale,” says Dr. Stefan Hartung, the chairman of the Bosch board of management. “

Dr. Stefan Hartung, the chairman of the Bosch board of management

The location in Roseville has existed since 1984. Over nearly 40 years, the U.S. company has built up vast expertise in semiconductor production. We will now be integrating this expertise into the Bosch semiconductor manufacturing network,” says Dr. Markus Heyn, member of the Bosch board of management and chairman of the Mobility Solutions business sector.

Dr. Markus Heyn, member of the Bosch board of management and chairman of the Mobility Solutions business sector

“We are pleased to join a globally operating technology company with extensive semiconductor expertise. We are confident that our Roseville location will be a significant addition to Bosch’s SiC chipmaking operations,” says Oded Tal, CEO at TSI Semiconductors.

Oded Tal, CEO at TSI Semiconductors

Acquisition of TSI Semiconductors creates new manufacturing capacity

The new location in Roseville will reinforce Bosch’s international semiconductor manufacturing network. Starting in 2026, following a retooling phase, first SiC chips will be produced on 200-millimeter wafers in a facility offering roughly 10,000 square meters of clean-room space. At an early stage, Bosch invested in the development and production of SiC chips. Since 2021, it has been using its own proprietary, highly complex processes to mass-produce them at its Reutlingen location near Stuttgart.

In the future, Reutlingen will also produce them on 200-millimeters wafers. By the end of 2025, the company will have extended its clean-room space in Reutlingen from roughly 35,000 to more than 44,000 square meters. “SiC chips are a key component for electrified mobility. By extending our semiconductor operations internationally, we are strengthening our local presence in an important electric vehicle market,” Heyn says.

Demand for chips for the automotive industry remains high. By 2025, Bosch expects to have an average of 25 of its chips integrated in every new vehicle. The market for SiC chips is also continuing to grow fast – by 30 percent a year on average. The main drivers of this growth are the global boom and ramp-up of electromobility. In electric vehicles, SiC chips enable greater range and more efficient recharging, as they use up to 50 percent less energy. Installed in these vehicles’ power electronics, they ensure that a vehicle can drive a significantly longer distance on one battery charge – on average, the possible range is 6 percent greater than with silicon-based chips.

Systematic investments in pivotal semiconductor technology

Semiconductors are key to the success of all Bosch business areas. The company recognized the potential of this technology early on, and has been producing semiconductors for more than 60 years. Bosch is one of the few companies to have not only electronic and software expertise but also a profound understanding of microelectronics. It can combine this decisive competitive advantage with its strength in semiconductor manufacturing.

The supplier of technology and services has been manufacturing semiconductors in Reutlingen since 1970. They are used both in the automotive sphere and in consumer electronics. Modern electronics in vehicles is also the basis for reducing traffic emissions, preventing road accidents, and efficient powertrains. Production at the Bosch wafer fab in Dresden (300-millimeter wafers) started in July 2021. At nearly one billion euros, the wafer fab is the biggest single investment in the company’s history.

In its wafer fabs in Reutlingen and Dresden, Bosch has invested more than 2.5 billion euros in total since 200-millimeter technology was introduced in 2010. On top of this, billions of euros have been invested in developing microelectronics. Independently of the investment now planned in the United States, the company announced in summer last year that it will be investing a further 3 billion euros in its semiconductor business in Europe, both as part of its investment planning and with the aid of the EU’s “Important Project of Common European Interest on Microelectronics and Communication Technologies” program.

Related Story

Mobility in the Software Age: Bosch to Realign its Automotive-Supply Business for Further Growth

“Software won’t only change how we use and experience cars in the future. It will also change the way cars are engineered. For some time now, Bosch has also seen itself as a mobility software company. Now, in response to customer requirements, our structure is changing to reflect this and to open up further growth.”

Dr. Markus Heyn, member of the Bosch board of management and the future chairman of the five-strong Bosch Mobility sector board