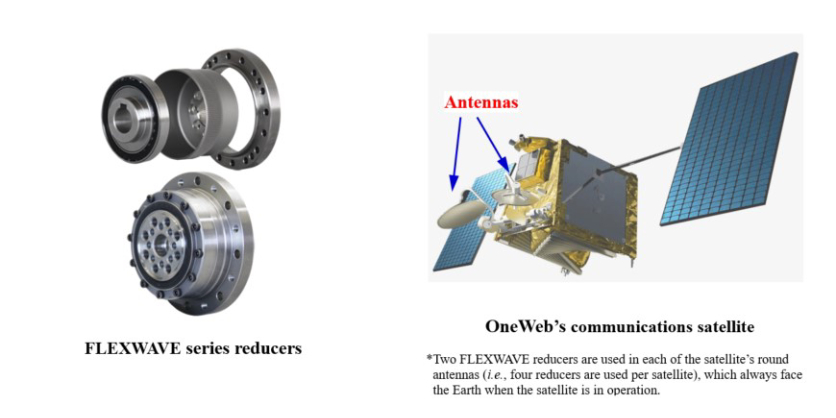

Nidec-Shimpo’s FLEXWAVE Precision Reducers are Essential for Use in Communications Satellites’ Antennas

Two FLEXWAVE reducers are used in each of the satellite’s round antennas

February 9, 2023

Nidec-Shimpo Corporation announced that precision control reducers of its FLEXWAVE series have been adopted to control the antennas of communications satellites produced by Canadian artificial satellite manufacturer MDA Ltd. (“MDA”). MDA, headquartered in Ontario, Canada, manufactures and sells artificial satellites, satellite systems, and robots for space use, among other products, and the Company’s FLEXWAVE reducers are used to control the antennas of MDA-produced satellites.

Since their launch in June 2015, the FLEXWAVE series reducers have been adopted for use in, for example, the joints of small industrial robots and the drives of semiconductor manufacturing equipment, and a total of more than one million units have been shipped as of the end of October 2022.

MDA’s satellites, which are used by OneWeb LLC, an Airbus-sponsored company, and have been decided lately to be adopted by another company (name undisclosed) as well. Among the approximately 3,000 FLEXWAVE reducers that have been shipped for controlling satellite antennas as of October 2022, none of them have been found defective so far, proving that the Company’s FLEXWAVE reducers meet the quality required for the space industry.

In recent years, the aerospace industry is booming overseas and elsewhere, partially thanks to the entry of private companies. Those reducers to be used for space satellites are required to be produced with advanced technology and are of high-quality, as they are exposed to a vacuum environment where lubricating their components is extremely difficult, with the temperature changing widely, and so instantly, within the range of approximately -120ºC to +130ºC.

We will stay committed to providing various fields with high-efficiency industrial machines that utilize our reducer-and continuously variable transmission-based know how and contributing to a variety of markets.

More Information

For more details on the above product, please contact Nidec-Shimpo Corporation’s Administrative Support Group (Tel.: +81-75-958-3670).

On April 1, 2023, Nidec-Shimpo Corporation will be renamed Nidec Drive Technology Corporation.

Related Story

MDA Selected By Lockheed Martin for Space Development Agency’s Tranche 1 Transport Layer Constellation

MDA Ltd., a leading provider of advanced technology and services to the rapidly expanding global space industry, recently announced it has been awarded a contract from Lockheed Martin as part of the Space Development Agency (SDA) Tranche 1 Transport Layer (T1TL) program.

MDA will design and build antennas and antenna control electronics for the 42 low Earth orbit (LEO) satellites to be produced by Lockheed Martin as part of SDA’s T1TL constellation. This includes steerable Ka-Band and Link-16 antennas, as well as the satellites’ GPS antennas.