The New SINAMICS S200 Servo Drive System from Siemens: Move Beyond!

March 12, 2024

By Krystie Johnston

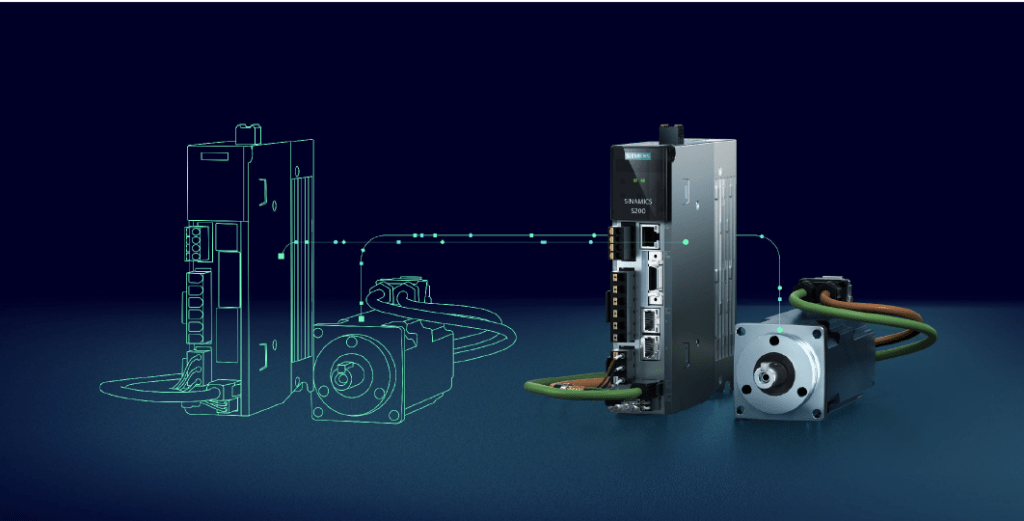

Siemens recently released their new SINAMICS S200 servo drive system. It is designed to address a wide range of standard applications, including battery, packaging, handling and robotics, metal forming, and other general machinery. The S200 has been optimized for performance, is easy to use, and is fit for the future. Bimal Shah P.Eng., Head of Product Management and Applications Engineering at Siemens Canada discusses their new servo drive system.

Bimal says, “The SINAMICS S200 servo drive system is ideal for dynamic applications thanks to fast current control. The system enables seamless communication to controllers via PROFINET IRT, providing fast and efficient data exchange and control. The integrated basic positioner (EPos) control mode controls the position of the motor in a closed-loop system, where the actual position of the motor is compared to the desired set point. Moreover, it is integrated in the drive, saving PLC resources.”

He adds, “One Button Tuning (OBT) enables machines to achieve high dynamic performance within seconds. The OBT feature is integrated directly into SINAMICS Startdrive, and the embedded SINAMICS webserver makes it easy to use. Finally, Safe Torque Off (STO) ensures safe and reliable operation, and User Management and Access Control (UMAC) provides active industrial security service, protecting the drive from unauthorized manipulations.”

The SINAMICS S200 servo drive system has been designed to be user friendly and efficient, providing a comprehensive solution for a wide range of standard applications.

Some of the features that make it easy to use:

- Compact Design: makes it easy to install and use in a variety of applications.

- Performance: ideal for applications that require fast and precise motion control.

- Ease of Use: easy to use and has a built-in webserver and one button-tuning.

- Reliable: optimized and efficient, a solution that is both reliable and cost-effective.

These features offer several benefits to the customer:

- Compact Design: reduces costs, saves space, and increases productivity.

- Performance: ensures fast and precise motion control – both speed and torque.

- Ease of Use: easy to install, operate, maintain, and reduces downtime.

- Reliable: operates smoothly without interruption, increasing performance output.

Higher productivity, improved efficiency, but at a lower cost – The SINAMICS S200 servo drive provides an ideal balance in today’s fast-changing market. For any customer looking to optimize their machines, this system is fit for the future.

Bimal says, “Having a future-proof servo drive is important for customers because it ensures that their investment in the system will not become obsolete in the future. A future-proof servo drive is designed to be compatible with new technologies and standards that may emerge in the future, which means that the system can be easily upgraded or modified to meet changing requirements. The SINAMICS S200 ensures that it will be future proof by offering a system that is performance-optimized, easy to use, flexible and compact, and scalable depending on the application.”

The SINAMICS S200 servo drive system consists of a precise servo drive (S200), powerful servo motors (S-1FL2), easy-to-use cables (MOTION-CONNECT 350 and 380) and offers highly dynamic performance. Thanks to TIA Portal integration, integrated web server (LAN/WLAN), and the One Button Tuning function, it is easy to operate. In combination with a SIMATIC Controller (i.e., SIMATIC S7-1500), users get a powerful, future-proof, robust motion control system.

Bimal says that the Siemens TIA Portal makes it easy for customers to select the components that make up the system. He says, “Siemens provides a TIA Selection Tool that helps customers select the hardware and firmware components necessary to implement a drive task. The tool provides support for selecting the power supply, drive, motor, cables, and other components that make up a system.”

“The tool also offers flexibility in the selection process, allowing users to choose from various communication options, such as PROFINET RT/IRT and Pulse Train. The SINAMICS S200 servo drive system is easily configured with the TIA Selection Tool under the Drive Dimensioning plug-in. The TIA Selection Tool is available for free,” he adds.

Configuring the SINAMICS S200 servo drive system is easy:

- Intuitive user interface, menu-based operation, and help.

- Configuration of the SINAMICS S200 servo drive system.

- Adjustable traversing cycles and various mechanical systems integrated for single-axis applications.

- Interface to the TIA Portal and SiePortal.

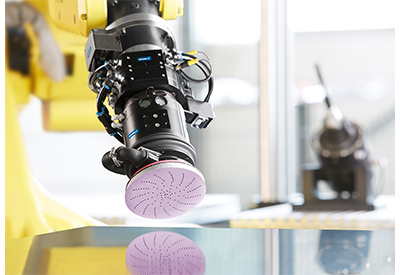

The SINAMICS S200 servo drive is well-suited to for many applications in various industries:

- Electronics

- Battery

- Solar

- Packaging

- Handling and Robotics

- Wood Working

- Metal Forming

- General Machinery

The technical specifications of the S200 have been designed to serve these industries. Some of these highlights are:

Advanced One Button Tuning (OBT)

- This feature enables machines to achieve a high dynamic performance within seconds.

Safety Integrated Basic Function Safe Torque Off (STO)

- This feature ensures safe and reliable operation.

Communication and Basic Positioner Epos:

- This feature provides powerful and precise positioning functions, and it can be used for a wide range of positioning tasks.

- Pulse Train Input Position Control (PTI) in the S200 provides precise and efficient positioning control for servo systems.

- PROFINT RT/IRT in the S200 provides high-speed, deterministic communication for precise speed control and positioning in industrial automation applications.

Holding Brake:

- Holds the position of the servo motor when it is not in motion. This is important for applications with hanging loads, where the brake can maintain the position so that the drive does not need to remain enabled in standstill or fault situations.

- As well as to dissipate the regenerative power for fast braking, which is easy and cost effective for applications.

The S200 servo system complies with global safety and performance standards, including CE, UUL, UKCA, KC, EAC, RCM, and SEMI47 certifications, which makes it easy to seamlessly integrate these servo drives into your existing systems, anywhere in the world. Selecting your ideal system is as simple as a few steps. (1) choose your dynamic servo motor, optimize it with a servo drive, and match the cables. Siemens’ configurator makes it easy, and for those customers who want additional support, Siemens is there.

When customers need support, Siemens is there with their Comprehensive Service Package. Bimal says, “Siemens Comprehensive Service Package is a service contract agreement that provides fast and effective support to customers throughout the entire lifecycle of their automation journey. The package consists of individually configurable service elements, tailored to the customer’s needs. This helps to increase cost-effectiveness for maintenance, optimization, and modernization. The service contact also assists in reducing wear, while extending the plant lifecycle – on-site and remotely.”

Customers typically need this support when they want to focus on their business, and leave the maintenance, optimization, and modernization of their plant with a reliable partner. The service agreement is industry-centered and adapted to the customer’s needs. It provides them with an individually coordinated service agreement that lets them focus on their business.

The new SINAMICS S200 servo drive system from Siemens has been optimized for performance, ease-of-use, and is future-proof. It is very flexible and scalable depending on the application. With a power range extending from 0.1kW up to 7kW and various communication options, this system has been specifically designed to address a wide range of standard applications.

Configure your SINAMICS S200 servo drive system today.

More Information

SINAMICS S200 servo drive system

Related Story

Siemens Canada: Automate The Future Tour 2024

Automate the Future Tour is coming to a city near you soon. This cross-Canada tour showcases the latest in manufacturing and process technologies. Explore all aspects of factory automation, motion, and process automation– from the hardware and software that drive it, the newest technologies, and fully-integrated solutions – that can transform your operations to win in this highly competitive marketplace. Register Now