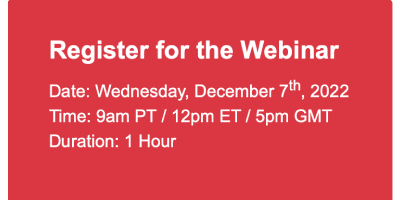

Mining & Quarry: Avoid Conveyor Downtime with NSK Solutions

November 30, 2022

Discover how NSK technologies can extend bearing life up to 10 times

Description

NSK presents advanced, field-proven solutions that have delivered exponentially longer bearing life in mine sites around the world.

You’ll discover how to achieve dramatic improvements to productivity and efficiency through an understanding of:

- •Root causes of bearing failure

- •Advanced bearing material technology for superior wear-resistance

- •Prevention with integrated and external sealing measures

- •Proof points – NSK success stories

Speaker

Nadeem Bhatti

Sr. Application Engineer

Nadeem is a University of Michigan B.A.Sc. Mechanical Engineering graduate and has been working in engineering since. In the last 8 years with NSK as an application engineer, he has been supporting customers across the US in various industries including medical.