IO-Link Safety Integrated in a Production Line | Pilz

July 15, 2024

Do you use a large number of safety sensors in your plant? Then IO-Link Safety is the solution for you! Take a look at the video and get a first impression of IO-Link Safety. The animation illustrates how IO-Link Safety can be integrated into an automation plant.

IO-Link Safety for flexible automation

IO-Link Safety is the extension of the IO-Link technology. It is a fieldbus and manufacturer independent communication solution for functional safety. IO-Link Safety enables safe, seamless communication from the controller to the safety-related sensors. It integrates sensors, actuators, and mechatronics into any existing fieldbus, information technology, or automation system. Simple field integration with rapid wiring and data diagnostic options offers huge potential to implement automation – flexibly and productively.

Your benefits at a glance:

- Safe and standardized point-to-point communication

- Standardized worldwide in IEC 61139-2

- Highest safety up to PL e / SIL 3 according to EN ISO 13849-1 / IEC 61508/62061

IO-Link Safety: a complete system, integrated in an automation plant

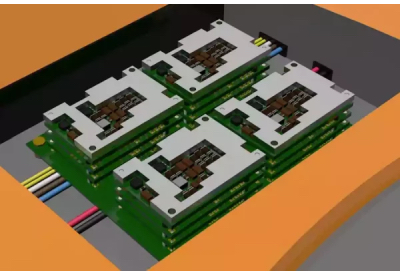

The animation shows a complete IO-Link Safety System integrated in an interlinked automation plant with integrated robotics. The access protection is realized with safety light curtains PSENopt II Advanced IOLS and the safeguarding of safety gates is done with a pushbutton unit PITgatebox IOLS and the safety locking device PSENmlock. All integrated via IO-Link Safety and the decentral Pilz IO-Link Safety master PDP67 PN 8FDIO 4IOLS. Besides the PITgatebox IOLS can be used as a IO-Link Safety hub for the safety locking device PSENmlock.

The IO-Link Safety technology enables the easy and fast installation of the safety sensors. The intelligent IO-Link devices offer extended diagnostic functions. With this new, predictive repair and maintenance concepts are possible.

Do you need customised advice on IO-Link Safety? Contact their experts now: www.pilz.com/io-link-safety

More Information

Further information about the Pilz IO-Link Safety system: IO-Link Safety

Related Story

Holistic, Safe System Solution from Pilz for IO-Link Safety, Comprising Master, Field Devices and Accessories – Safe Connectivity at Field Level

For the first time, a complete IO-Link Safety System is available for safe communication at field level: The system solution from Pilz comprises Master, as well as field devices and compatible accessories. Among the first devices in the Pilz portfolio to be equipped with IO-Link Safety functionality are the safety light curtains PSENopt II advanced IOLS, the control unit PITgatebox IOLS and the IO-Link Safety Master PDP67 IOLS. The complete package from the expert in safe automation makes it easier to integrate IO-Link Safety technology into plant and machinery.