Honda Plans to Establish Comprehensive Electric Vehicle Value Chain in Ontario, Canada

May 1, 2024

- Honda to strengthen electric vehicle (EV) supply system and capability with an eye toward a future increase in EV demand in North America

- Honda to support global initiative to make BEVs and FCEVs represent 100% of vehicle sales by 2040 by investing approximately CAD$15 billion, including investment by joint venture partners, to build a comprehensive electric vehicle value chain in Canada

- Plan follows Honda EV Hub project in Ohio in the United States and will represent a significant aspect of the company’s overall value chain in North America

- Initiative represents recognition of the long-term attractiveness of the Canadian EV manufacturing ecosystem

Honda Motor Co., Ltd. has announced that it plans to build a comprehensive EV value chain in Canada with an approximate investment of CAD$15 billion, including investment by joint venture partners, to strengthen its EV supply system and capability to prepare for a future increase in EV demand in North America. Honda has begun evaluating the requirements to build an innovative and environmentally responsible Honda EV plant and a stand-alone Honda EV battery plant in Alliston, Ontario. The proposed Honda EV value chain will also include a cathode active material and precursor (CAM/pCAM) processing plant through a joint venture partnership with POSCO Future M Co., Ltd. and a separator plant through a joint venture partnership with Asahi Kasei Corporation, with announcements to follow in their respective Ontario communities.

Honda expects that electric vehicle production will begin in 2028. Once fully operational, the EV plant will have a production capacity of 240,000 EVs per year and the EV battery plant will have a capacity of 36 GWh per year. In addition to securing the current employment level of 4,200 associates at its two existing manufacturing facilities in Ontario, Honda estimates it will add a minimum of 1,000 new associates for the EV and EV battery manufacturing facilities. The investment in the new facilities will also create significant spinoff jobs across all sites, including in the construction sector.

Honda has begun the process of evaluating the scope of its investment and completing negotiations with its joint venture partners. This work is expected to be finalized during the next six months and more details will be shared at that time.

To support this project, Honda is collaborating with the governments of Canada and Ontario to drive innovation in low-emissions manufacturing by accessing performance-based initiatives available through the federal government’s new Investment Tax Credits and provincial direct and indirect incentives.

North American EV strategy

Striving to realize carbon neutrality for all its products and corporate activities by 2050, Honda has set a goal to make BEVs and FCEVs represent 100% of vehicle sales by 2040. To achieve this goal, Honda will continue offering attractive products in this electrified era globally, including its largest market of North America.

As the first step in achieving this electrification goal in North America, Honda positioned its existing auto production plants in the state of Ohio in the U.S. as its EV Hub for production, including the retooling of existing plants, an investment of USD$700 million, and the construction of a joint venture EV battery plant with LG Energy Solution, with an expected investment of USD$4.4 billion.

The Ohio EV hub will serve as the foundation for future EV and EV battery production, sharing knowledge and expertise with other Honda plants in North America, including the new EV assembly and battery plants in Ontario, Canada. Honda expects EV production to begin at the Marysville Auto Plant in late 2025.

As a second step in this initiative, Honda will strive to establish a comprehensive EV value chain that includes all aspects of EV production in Canada, from the procurement of raw materials mainly for batteries, to the production of finished EVs. Honda will leverage EV production knowledge learned at the Ohio EV Hub, combined with the abundant resources and clean energy available in Canada, to establish a stable supply system for batteries, the key component of EVs, and increase cost competitiveness of its EVs as a whole.

Furthermore, with an eye toward secondary use and the recycling of batteries, Honda will realize low-carbon value creation throughout the entire battery life cycle, through which Honda will establish a highly profitable business foundation and contribute to the realization of a carbon-neutral society.

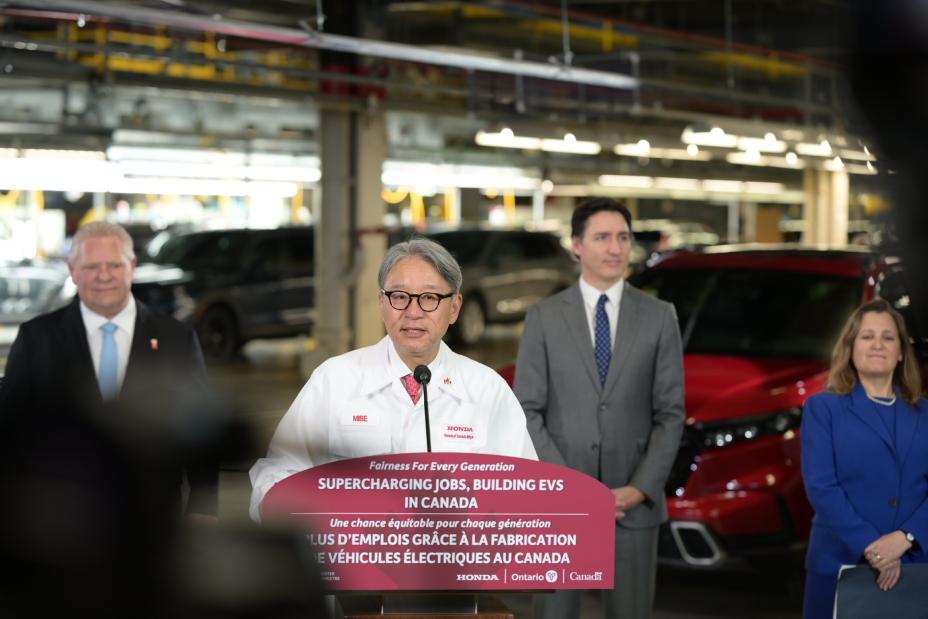

“Honda is making progress in our global initiatives toward the realization of our 2050 carbon neutrality goal. In North America, following the initiative to establish our EV production system capability in the U.S., we will now begin formal discussions toward the establishment of a comprehensive EV value chain here in Canada, with the support of the governments of Canada and Ontario. We will strengthen our EV supply system and capability with an eye toward a future increase in EV demand in North America.”

Toshihiro Mibe, Global CEO of Honda

“Honda of Canada Manufacturing is one of the premier automotive manufacturing facilities in the world and for nearly forty years, our work has been guided by determination, innovation, and a relentless drive to evolve. Today’s announcement is a historic investment by a manufacturer in the Canadian auto industry. It proudly honours the highly skilled associates who have earned a global reputation for manufacturing excellence and represents Honda’s recognition of the long-term attractiveness of the Canadian electric vehicle manufacturing ecosystem.”

Jean Marc Leclerc, President and CEO of Honda Canada Inc.

About Honda Motor Co., Ltd.

Honda Motor Co., Ltd. is responsible for the development, production and sales of automobiles, motorcycles, power products and aviation products worldwide. Honda now delivers over 28 million products annually through its three product lines. Honda and its partners build products in more than 60 manufacturing plants in 27 countries, employing about 197,000 associates globally. On a global basis by 2050, Honda is striving to achieve carbon neutrality for all products and corporate activities, as well as zero traffic collision fatalities involving Honda automobiles and motorcycles.

About Honda Canada Inc.

Honda Canada Inc. was founded in 1969 and is the parent company for both Honda and Acura vehicle brands in Canada. Since 1986, the company has produced Honda engines and more than 10 million cars and light trucks at its Alliston, Ontario manufacturing facilities, where Honda Civic and Honda CR-V are currently built. Honda has invested over $6.5 billion in Canadian operations, and each year sources over $3 billion in goods and services from Canadian suppliers. Since its inception, Honda Canada has sold over five million Honda and Acura passenger cars and light trucks in Canada through a dealer network of more than 280 dealerships across the country. For more information, please visit www.hondacanada.ca.

About Honda of Canada Mfg.

Honda of Canada Mfg. (HCM) began production in Alliston, Ontario in November 1986 and is Honda’s only manufacturing facility in Canada. HCM’s plants sit on 890 acres, encompass approximately 4 million square feet, and employ 4,200 associates. The plants have the capacity to produce more than 400,000 vehicles each year combined. HCM manufactures two of Honda’s best-selling models, the Honda Civic and the CR-V, and produced its 10 millionth vehicle in 2023. For more information, please visit www.hondacanadamfg.ca.

Related Story

Honda to Build Canada’s First Comprehensive Electric Vehicle Supply Chain, Creating Thousands of New Jobs in Ontario

From mining critical minerals to building cars and batteries, Canadian businesses and workers are attracting historic investments to help secure and create jobs, grow our economy, and keep our air clean. In the last four years, automotive and battery makers have announced more than $31 billion in investments in electric vehicle manufacturing across Canada. They want a reliable partner with world-class talent, and this is exactly what we have to offer.