Highlighting Circularity, Ninety-One Percent of Industrial Businesses Hit by Resource Scarcity

January 29, 2024

While there is optimism about investing in circularity, the survey also identified obstacles to immediate progress

- New report shows resource scarcity is leading to increased costs, supply chain disruption, and slowdowns in production.

- Most businesses support circularity regulations and will invest more over the next three years, despite the lack of a standardized approach and slow adoption of key practices.

- Improving circularity is closely connected with energy efficiency, with energy topping the list of the biggest sources of waste.

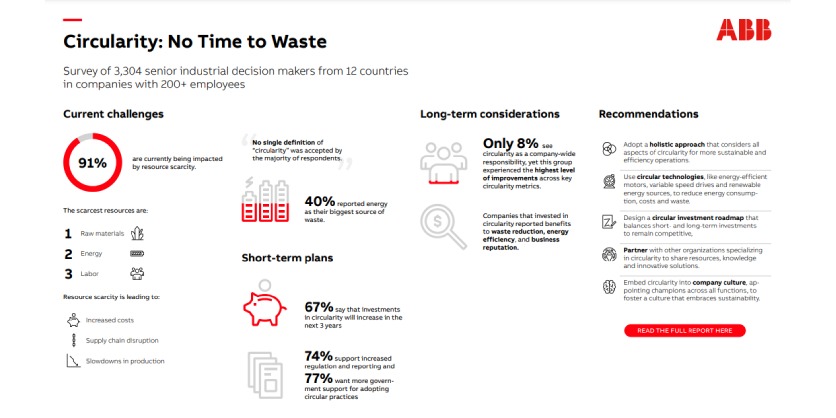

A new report from ABB Motion, entitled “Circularity: No Time to Waste,” reveals that 91 percent of industrial businesses are feeling the effects of resource scarcity, prompting two-thirds to increase their investment in circularity initiatives within the next three years.

Raw materials (37 percent) are seen as the scarcest resource, followed by energy (34 percent), labor (32 percent), and electronic components (26 percent). This resource scarcity has led to increased costs for 37 percent of businesses, as well as supply chain disruption for 27 percent and slowdowns in production capacity for 25 percent. Despite energy being rated as the scarcest resource, two-fifths reported it as their biggest source of waste. This highlights an urgent need for greater energy efficiency across industry, something the International Energy Agency (IEA) says will be a critical lever in meeting Net Zero targets.

The global survey, conducted by Sapio Research in October 2023, gathered responses from 3,304 industrial decision-makers across 12 countries including the US, China, India, UK, Sweden, Germany, and France. Respondents represented a range of industries, such as energy, metals, chemicals, oil and gas, marine, mining, and utilities.

While there is optimism about investing in circularity, the survey also identified obstacles to immediate progress. For example, no single definition of “circularity” was accepted by the majority of respondents. Also, only eight percent see circularity as a company-wide responsibility, but this group experienced the highest level of improvements across key circularity metrics, such as energy consumption, use of recycled materials, and carbon emissions.

The survey also reveals that many important circular practices have still only been adopted by a minority of businesses, including partnering with waste management companies (41 percent), incorporating energy-efficient technologies (37 percent), and promoting circular principles in the supply chain (32 percent). Encouragingly, 67 percent are using recycled materials in their products to some extent.

Investing in circularity has already led to measurable benefits, with the most common being waste reduction (46 percent) and energy efficiency improvements (45 percent). Although some businesses express concern about the upfront investment required, many anticipate long-term improvements in process efficiency and cost control.

Most respondents (78 percent) agree that the circular economy encourages innovation and drives competitiveness. They also support increased regulation and reporting requirements (74 percent) and want more government support for adopting circular business practices (77 percent).

Tarak Mehta, President of ABB Motion, commented: “The pressing need to transition to a circular economy has never been clearer. Our current way of life is depleting resources at an unsustainable rate, contributing to emissions and climate change. Embracing circularity is not only essential for safeguarding our environment but also for enhancing business resilience.”

“This survey highlights the importance of taking a holistic approach, instilling responsibility at all levels of the organization, and embracing new technologies and collaborations. While there are challenges to overcome, businesses that fully embrace circularity see significant benefits, from cost control to improved reputation. We must act now, to make circularity the norm in global industries. There is no time to waste.”

To consult the full report, click here

ABB Motion keeps the world turning – while saving energy every day. We innovate and push the boundaries of technology to enable the low-carbon future for customers, industries and societies. With our digitally enabled drives, motors and services our customers and partners achieve better performance, safety and reliability. We offer a combination of domain expertise and technology to deliver the optimum drive and motor solution for a wide range of applications in all industrial segments. Through our global presence we are always close to serve our customers. Building on more than 140 years of cumulative experience in electric powertrains, we learn and improve every day. go.abb/motion

Related Story

Research Reveals Energy Concerns Impacting Business Competitiveness, The Workforce and Decarbonization

Research shows that businesses around the world remain concerned about the impacts of energy security and prices, which could be a catalyst for a range of environmental, social and economic ripple effects. According to ABB Electrification’s Energy Insights survey1 of 2,300 leaders from small and large businesses across a range of sectors, 92 percent of respondents feel that the continuing instability of energy is threatening their profitability and competitiveness. Energy costs and insecurity are having a significant impact on the workforce with decreased investment in employees. Business leaders are also concerned about potential impacts of meeting their sustainability targets.