GHGSat Doubles Capacity to Monitor Methane Emissions with Three New ABB-Built Optical Sensors

May 30, 2022

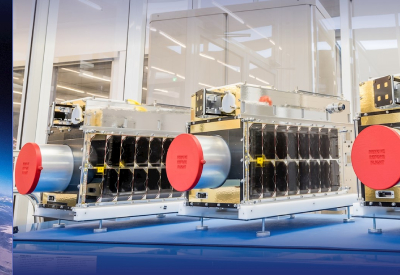

Canadian company GHGSat, which specializes in high-resolution GHG monitoring from space, launches three new ABB-built optical sensors into space aboard a SpaceX Falcon 9 rocket from Cape Canaveral Space Force Station, doubling capacity to monitor methane gas emissions.

GHGSat’s hyperspectral imaging technology accurately locates and measures methane emissions from any given industrial site on earth. The launch of three new ABB-built high-resolution methane sensors doubles the company’s capacity to monitor customer sites. In addition to the three units being launched – Luca, Penny and Diako –five additional units dedicated to methane measurements are under fabrication at ABB.

Space is the only location allowing emissions to be monitored freely across jurisdictions and report on improvements or otherwise. Measuring different sites with the same sensor ensures that emissions are compared consistently. Space measurements are also especially useful for sites where ground sensors are economically not viable or too complex to deploy.

GHGSat announced the initial constellation contract with ABB in October 2020, with first deliveries started in 2021. The launch of three additional units strengthens GHGSat’s lead in-orbit, operating the world’s largest constellation in the world dedicated to GHG emission monitoring.

According to the International Energy Agency, methane is responsible for around 30 percent of the rise in global temperatures since the Industrial Revolution, and rapid and sustained reductions in methane emissions are key to limiting near-term global warming and improving air quality1.

“Satellite data is critical for stakeholders globally to take immediate action for a sustainable future. The first full year of commercial operation for GHGSat satellites confirmed the impact our technology can have. We’re excited to double our capacity and accelerate the change needed to make a difference for our planet,” said Stephane Germain, CEO of GHGSat.

Watch this video to see how ABB sensors map greenhouse gases from space

{videobox}OddMdRK8-1s{/videobox}

“This is an exciting milestone for our team as we witness the efficiency of applying our serial production knowhow to space sensors manufacturing which in the past have been mainly one-off contracts. Our partnership with GHGSat led to a paradigm shift in the industrial space sector. Not only does this set new standards in our space offering for the private sector which is growing at a rapid pace, but it also allows us to expand our expertise and solutions offering,” said Marc Corriveau, General Manager ABB Measurement & Analytics Canada.

For more than two decades, with involvement in the Canadian SCISAT mission and the Japanese GOSAT satellites program, ABB has stood at the forefront of greenhouse gas sensing from space. ABB optical equipment already in space cumulates more than 100 years of reliable operation. Since 2003, the SCISAT sensor tracks long-term subtle composition changes in the Earth’s atmosphere down to parts per trillion of more than 70 molecules and pollutants. Weather agencies across the world base their predictions on ABB equipment flying onboard the US National Oceanographic and Atmospheric Administration (NOAA) weather satellites (NPP and JPSS), which improves the timeliness and accuracy of weather forecasts for up to seven days, helping save lives through advanced warning evacuations.