EXOR: Control Engineering Webcast – Overcoming the Limitations of Human-Machine Interfaces

September 14, 2021

Event: Control Engineering and EXOR webcast

When: Wednesday, September 22 at 11 am PT / 1 pm CT / 2 pm ET

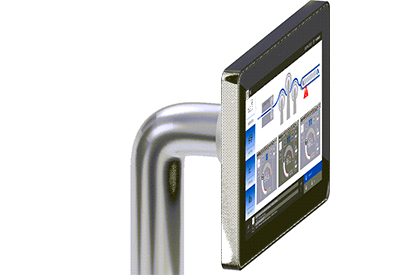

Human-machine interface (HMI) displays have long suffered from a variety of design limitations, from bulky, immobile enclosures to tangled cables and connectivity challenges.

Yet despite the frustration and inefficiencies these restrictions cause every day, they’ve traditionally been accepted as necessary evils by equipment manufacturers and end users.

It’s no longer necessary to settle for the limitations of traditional HMI displays, even or harsh or demanding environments.

A variety of cost-effective innovations now make it possible for HMI displays to overcome limits in ways that save considerable time, cost, and frustration for original equipment manufacturers (OEMs) and end users alike.

Learning Objectives:

- – Learn how to eliminate the need for bulky enclosures, simplify physical connections and enable Wi-Fi connectivity

- – How to eliminate common frustrations and enable efficient workflows

- – Explore how to reduce HMI equipment footprint and total cost of ownership