Endress+Hauser Lays the Groundwork For The Future At the Reinach Location

July 8, 2022

The company creates more space for the production of flow measurement technology as well as the development of Industry 4.0 solutions.

Endress+Hauser continues on the path to growth. Over the past five years the number of employees at the Reinach location in the Swiss canton of Basel-Landschaft has grown by 20 percent to more than 2,000. At the same time, the number of units produced has significantly increased and the digital solutions portfolio has expanded. In order to simultaneously meet the new demands of the work environment, vocational training positions and digitalization, the measurement and automation technology specialist invested 60 million Swiss francs in the Reinach campus.

The nearly 150-meter-loing building boasts 25,000 square meters of additional space

After beginning work on the foundations in 2019, Endress+Hauser will celebrate the opening of the nearly 150-meter-long building in Reinach on 1 July 2022. The construction plan included the use of available property and an existing building located on Kägenstrasse. The new facility, which boasts more than 25,000 square meters of space, equivalent to around four soccer fields, was built with roughly 19,000 cubic meters of concrete and 2,200 tons of reinforced steel and other materials.

The new building is home to Endress+Hauser Flow, the product center for flow measuring technology, as well as Endress+Hauser Digital Solutions, which is responsible within the Group for all issues related to digital communication and automation solutions. The first wave of employees has already moved into the facility.

Production expansion and additional jobs

With the new building, Endress+Hauser is responding to the ongoing demand for high-quality instrumentation and solutions for Industrial Internet of Things (IIoT) environments in the process industry. Liquids and gases must always be monitored, measured and settled with a high degree of accuracy. This is being driven, among other things, by increasingly strict government regulations and growing requirements on quality and environmental protection around the world.

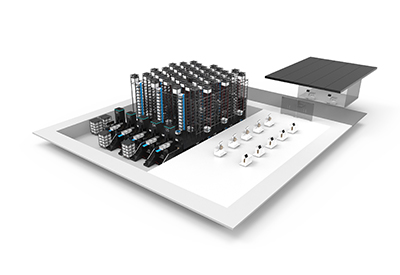

Among other products, Endress+Hauser manufactures high-quality flowmeters in Reinach for monitoring and measuring liquids and gases

Endress+Hauser Flow has reacted to this development, expanded its portfolio and doubled the number of units produced over the past decade. The consequence is continuous expansion of the production capacity and the creation of additional jobs. With the most recent developments, the family company is making a clear commitment to Reinach and the Basel region where the Group is firmly rooted.

Focus on collaboration

As a result of the expansion, around 1,050 employees will move across all buildings. The additional space will create more collectively used workspace. “In the spirit of ‘New Work’, we are implementing activity-based working. Different work areas will be available for different activities, meaning that our employees can choose the space best suited to their individual tasks,” says Mirko Lehmann, Managing Director of Endress+Hauser Flow.

Special coworking zones such as Innovation Labs or project zones furthermore offer different departments the opportunity to collaborate on longer-term projects. Employees can choose between a permanent or shared desks. Bright, friendly spaces and a modern infrastructure have a positive impact on the work environment as well.

Learning-conducive training environment

For Endress+Hauser, laying the groundwork for the future also means investing in the employees of tomorrow. The new building brings training and education into the heart of operation and offers sufficient space for areas conducive to learning with workshops, labs and training rooms, thus allowing an increase in the number of apprenticeship positions and vocational careers.

To date, 43 apprentices have been trained in eight areas. Beginning in August, nearly 50 apprentices will be trained in 11 vocations. This number is expected to grow over the next five years.

The new building contains learning-conductive areas with workshops, labs, and training rooms

Around 4,000 annual visitors can look forward to the new plant tour and hospitality concept. This concept consists of a redesigned reception area and a new visitor center including “Flow Experience”, an integrated 2,000-square-meter area where the Endress+Hauser brand and flow instrument portfolio can be experienced before taking a tour of the plant.

Sustainable energy concept

Endress+Hauser is furthermore using the new building to align its ongoing business growth even more closely with its ecological and social responsibilities. In light of the goal of the Endress+Hauser Flow sustainability strategy to operate its buildings in Reinach in a CO2-neutral manner by the year 2030, high value is being placed on climate-friendly facilities management.

As part of the energy concept, for example, waste heat is stored in a stratified storage tank for warm water and then used for heating. A comprehensive energy monitoring system using instruments from the company’s own portfolio also helps to continuously optimize operation of the buildings.

Endress+Hauser is one of the largest producers of solar electricity in the Basel region

Large photovoltaic systems were installed on the roof of the new building, which boast a peak capacity of 365 kilowatts, enough to cover the annual electricity needs of around 75 single-family homes. In Reinach, Endress+Hauser now has photovoltaic systems covering more than 3,700 square meters with a total peak capacity of roughly 1 megawatt, making the company one of the largest solar power producers in the Basel region.

The roof is also home to two bee colonies and various bee-friendly flowers, a project that contributes to the preservation of biodiversity as these small insects are considered central Europe’s most important plant pollinators.