Endress+Hauser and Purdue IN-MaC Collaborate to Cultivate STEM-Learning Opportunities

September 20, 2022

Design and Innovation Studio opened to educate and inspire the next generation of STEM leaders through interactive learning.

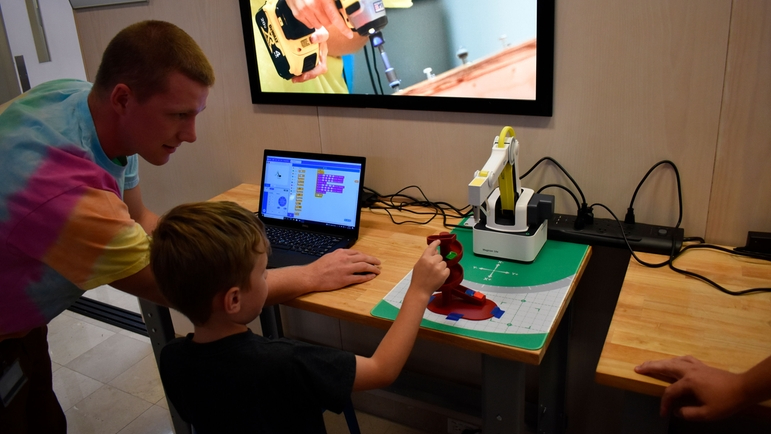

On September 15th, Endress+Hauser inaugurated its Design and Innovation Studio, a center equipped with Industry 4.0 technology and STEM-learning opportunities for students K-8 as well as applications for high school students. In partnership with Purdue Indiana Next Generation Manufacturing Competitiveness Center (IN-MaC), the process automation manufacturer welcomed local educators, guidance counselors, and teachers to the grand opening of its new center. The center offers 3D printing, robotics, Spheros, Little Bits, engineering and science modules, and coding. Teachers can reserve the space as an extension of their classroom activities as all curriculum is aligned with Indiana State Standards.

“After years of engagement and awareness through established activities with middle and high school students, this Design and Innovation Studio provides our organization the opportunity to create career and early STEM awareness for younger students,” said Nicole Otte, Director of Workforce Development, Endress+Hauser. “It further expands our early talent initiatives. We really look forward to partnering with local educators to integrate this studio into their curriculum.”

Additional studio expands educational offering

In addition to opening the Design and Innovation Studio at the Endress+Hauser location, the two organizations were able to fund another Design and Innovation Studio at a different local location in Johnson County. The second location will serve Indian Creek Elementary, Intermediate and Junior High School.

“IN-MaC is thrilled to be partnering with Endress+Hauser to build awareness and increase access and equity in STEM educational pathways,” said Sascha Harrell, director of education and workforce for IN-MaC. “This collaboration is designed for students and teachers to gain skills required to succeed in the innovation-focused twenty-first century, learn more about STEM careers, challenge their understanding of the industry, and leverage their interests to inspire participation and prepare youth for future jobs.”

Endress+Hauser STEM LEAD challenges conventional learning

Concurrently with the opening of the Design and Innovation Studio, Endress+Hauser also kicked off its Youth STEM LEAD program for high school students. This initiative allows high schoolers the opportunity to interact with and learn directly from Endress+Hauser subject matter experts. This program offers a free 90-minute session once a month for students to explore career opportunities within the STEM field. Each session will feature a new topic, some of which were specifically chosen ahead of time, while the remaining will be chosen by participants via an online survey to provide students the unique freedom to have control over their learning experience.

Please click here to learn more.