Comau to Develop Innovative Cell Formation & Testing Technology Solutions for National Institute of Chemistry in Slovenia

October 21, 2024

- Comau is tasked with industrializing flexible machines for advanced cell formation and testing of next-generation cell technologies

- The collaboration underscores Comau’s leadership in industrial automation and its commitment to advancing efforts toward a carbon-free future

- The innovative installation ensures precise temperature control, optimal current levels, and secure handling during the cell formation and testing phases, enhancing safety and efficiency

Comau has secured a public tender with the National Institute of Chemistry in Slovenia, to industrialize flexible machines for advanced cell formation and testing. The collaboration aims to develop and industrialize flexible machines for the formation and testing of advanced cell technologies at varying working temperatures. The project was started in June, and is expected to end by the end of 2025.

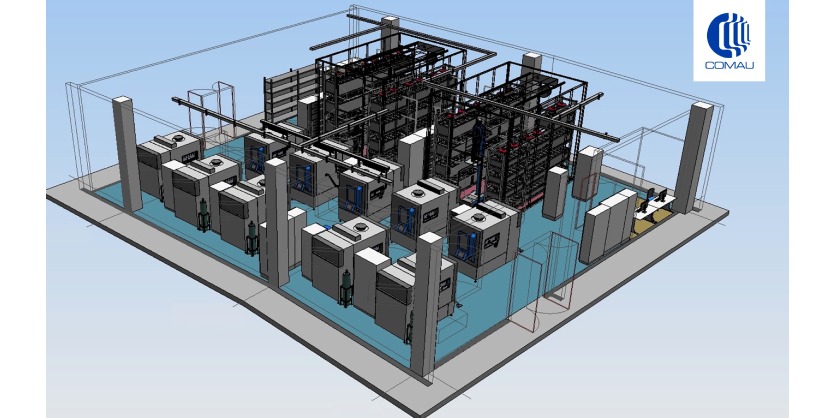

The scope of the project is to deliver a technology path (from design to installation and commissioning) for the industrialization of flexible machines that manage both the formation and testing of various cell formats. The cell formation process must be able to handle both pouch and prismatic cell formats, whereas Comau is tasked with ensuring comprehensive testing capabilities for pouch, prismatic, and cylindrical cell formats. Furthermore, the tests must cover a wide range of working temperatures, from room temperature to sub-zero conditions.

This project not only showcases Comau’s leadership in industrial automation but also underscores the increasing importance of flexible and advanced cell formation and testing technologies within the evolving battery landscape. Indeed, Comau’s collaboration with the National institute of chemistry. highlights the company’s commitment to pushing the boundaries of research and development in next-generation cell technologies and supporting the transition to a carbon-free reality.

One of the most challenging aspects, which is also a critical component of the initiative, is the management of a diverse range of cell dimensions, in addition to accommodating cells from external sources. To achieve this, Comau has engineered specific and flexible tooling for secure safe handling and precise connectivity. Both of which can be integrated with the climatic chambers for precise temperature control and advanced power electronics that ensure optimal current levels. Another important element was to design the machines with the most appropriate level of automation complexity considering the tooling would be handled by scientists and other operators. In every aspect of the set-up, safety must be considered the priority, both in terms of the materials to be handled as well as overall accessibility and maintainability. For example, there are no manual couplings between the tooling and the climatic chambers, such that the operator can easily and safely configure the tooling based on the products to be processed. Comau has also engineered a sophisticated software interface to allow operators to control processes and input specific parameters efficiently.

“The opportunity to work with an innovative and authoritative organization such as the Slovenian National Institute of Chemistry confirms our steadfast research in the field of next generation electrification enablers in order to provide our customers with best-in-class solutions”, said Andrew Lloyd, Comau Chief Engineering Officer. “Comau’s comprehensive competencies and cutting-edge technologies span the spectrum from batteries to e-motors, and from cell formation to innovative hairpin stator technologies. All of which underscore our commitment to helping drive the evolution of e-mobility by ensuring superior performance, reliability, and sustainability during every stage of our customers’ journey.”

ABOUT COMAU

Comau is a worldwide leader in delivering sustainable advanced automation solutions. With 50 years of experience and a global presence, Comau is helping companies of all sizes in almost any industry leverage the benefits of automation. Backed by a continuous commitment to designing and developing innovative and easy to use technologies, its portfolio includes products and systems for vehicle manufacturing, with a strong presence in e-Mobility, as well as advanced robotics and digital solutions to address rapidly growing markets in industrial sectors.

The company’s offering also extends to project management and consultancy. Through the training activities organized by its Academy, Comau is committed to advancing the technical and managerial knowledge necessary to face the challenges related to automation and leverage the opportunities of a constantly changing marketplace. Headquartered in Turin, Italy, Comau has an international network of 7 innovation centers and 12 manufacturing plants that span 12 countries and employ 3,700 people. Together with its wide network of distributors and partners, the company is able to respond quickly to the needs of its customers, no matter where they are located throughout the world.

More Information

Related Story

Comau Showcased Its New and Powerful Turnkey E-Mobility Solutions at The Battery Show 2024

Comau, a global technology company and pioneer in advanced battery production technologies, attended The Battery Show Europe conference, held at Germany’s Messe Stuttgart from 18-20 June (booth number 9-F50). Billed as Europe’s largest event for the battery and EV tech communities, Comau leveraged the platform to show its latest proprietary technologies, products and solutions designed to support customers at all stages of the electrification process – from lab-based prototypes to giga-scale production of batteries and hydrogen fuel cells and electrolyzers. In addition, the company offers highly efficient systems for e-drives, hybrid transmissions, components and complete assembly lines.