How to Quickly Leverage Bluetooth AoA and AoD for Indoor Logistics Tracking

Jeff Shepard

March 30, 2023

Real-time asset tracking in warehouses and factories is an important aspect of Industry 4.0. Various technologies are available for deploying Real-Time Location Services (RTLS) for asset tracking and improving logistics systems. Global Positioning Systems (GPS) are widely used for outdoor RTLS implementations, but the signals are not always available inside buildings. Wi-Fi is another choice, but it tends to have limited accuracy, requires significant power, and can be costly to deploy. Radio-frequency identification (RFID) is low power and has good accuracy but tends to be expensive. Industry 4.0 RTLS installations are increasingly turning to Bluetooth 5.1 direction-finding techniques because they combine high precision indoor positioning plus low power consumption, low cost of Bluetooth hardware, and low cost of deployments.

It can be tempting for developers to design Bluetooth RTLS systems from scratch. Unfortunately, obtaining the radio frequency (RF) in-phase and quadrature (IQ) information of the angle-of-arrival (AoA) and angle-of-departure (AoD) data required to calculate the position of a transceiver from the RF signal is challenging and requires the integration of multiple antennas. Even if the AoA and AoD data can be captured, location calculations can be complicated by numerous factors, including multipath propagation, signal polarization, propagation delays, jitter, noise, and more, before the location of the item being tracked can be accurately determined.

Instead, designers can turn to Bluetooth wireless systems on chips (SoCs), RF modules, and antennas for use in Industry 4.0 RTLS applications. This article briefly reviews the performance tradeoffs of the various RTLS technology choices and describes how Bluetooth AoA and AoD location is implemented. It then presents Bluetooth SoCs and RF modules that include the software needed to quickly implement AoA and AoD-based RTLS, as well as related antennas from Silicon Labs and u-blox. Evaluation kits that can further speed time to market are also presented.

The most commonly used indoor RTLS technologies are implemented using Wi-Fi and Bluetooth (Table 1):

- Wi-Fi fingerprinting uses a database of the location and base station ID (BSSID) of each Wi-Fi access point (AP) in a building. An asset tag scans the Wi-Fi environment and reports the list of Wi-Fi APs and their associated signal strengths. The database from the survey is then used to estimate the tag’s likely position. This technique does not support high-accuracy RTLS.

- Wi-Fi Time of Flight (ToF) is more accurate. It measures the time it takes for Wi-Fi signals to travel between devices. ToF requires a dense deployment of APs to improve the accuracy of RTLS. Both ToF and fingerprinting have high device costs and high energy requirements.

- Bluetooth received signal strength indicator (RSSI) supports RTLS by enabling devices to determine their approximate distance from nearby Bluetooth beacons by comparing the received signal strength with known beacon positions. RSSI uses less energy and is lower cost than Wi-Fi fingerprinting or ToF, but it has limited accuracy. Its accuracy can be further reduced by environmental factors such as humidity levels and robots, or people moving around a facility and interfering with the Bluetooth signal levels.

- Bluetooth AoA is the newest and the most accurate indoor RTLS technology. In addition to providing high accuracy, it uses relatively little power and is low cost. However, it’s more complex to implement compared with the other alternatives.

| Wifi Fingerprinting | Wifi Time-of-Flight | Bluetooth RSSI | Bluetooth AoA | |

|---|---|---|---|---|

| Accuracy | 10 m | 1 m to 2 m | 5 m to 10 m | 0.5 m to 1.0 m |

| Power Consumption | High | High | Medium | Low |

| Installation Cost | Low | Medium | Low | Medium |

| Device Cost | High | High | Low | Low |

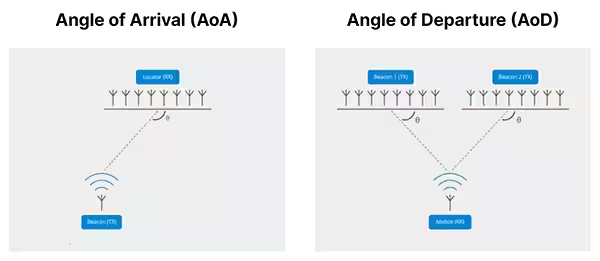

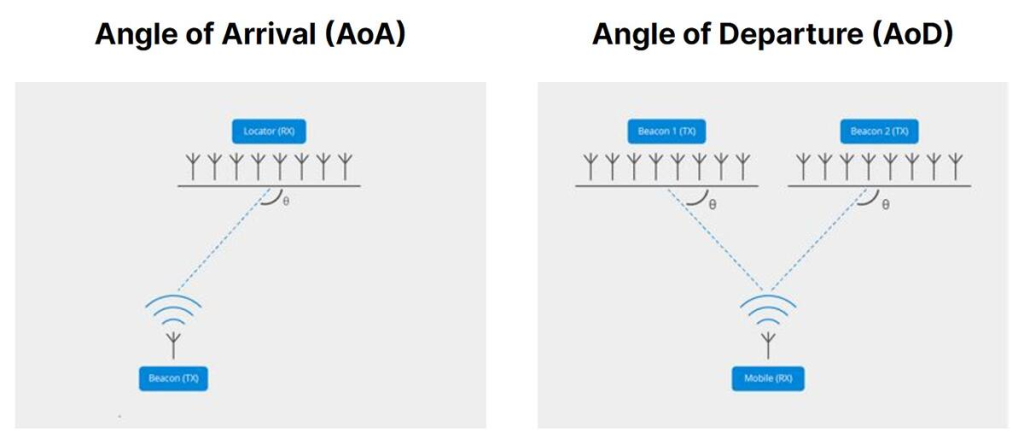

Bluetooth AoA and related AoD, RTLS solutions rely on antenna arrays to estimate the position of an asset (Figure 1). In an AoA solution, the asset sends a specific direction-finding signal from a single antenna. The receiving device has an antenna array and measures the signal phase difference among the various antennas caused by the differing distances of each antenna from the asset. The receiving device obtains IQ information by switching between the active antennas in the array. The IQ data is then used to calculate the location of the asset. In an AoD solution, the locator beacon to which the location is being determined transmits the signal using multiple antennas in an array and the receiving device has a single antenna. The receiving device uses multiple signals to determine the IQ data and estimate its position. AoA is often used for tracking the position of assets, while AoD is the preferred technique to enable robots to determine where they are in a facility with good accuracy and low latency.

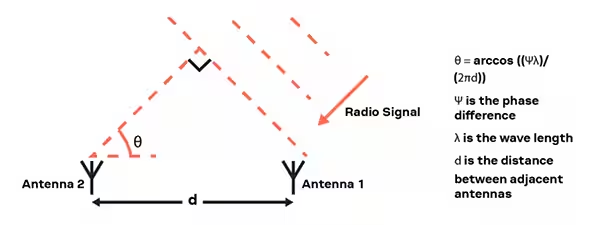

The basic concept for AoA-based RTLS tracking is straightforward: Θ = arccos x ((phase difference x wavelength) / (2 π x distance between the antennas)) (Figure 2). Real-world implementations are more complicated and need to account for signal propagation delays caused by environmental variables, multipath signals, varying signal polarization, and other factors. In addition, when antennas are used in an array, they can experience mutual coupling and affect each other’s responses. Finally, it can be quite challenging to develop the algorithms needed to take all of these variables into account and efficiently implement them in a time-critical solution in a resource-constrained embedded environment. Fortunately for developers, complete Bluetooth AoA and AoD solutions include IQ data collection and preprocessing, multipath components suppression, compensation for environmental factors, and mutual coupling between antennas.

SoCs for Bluetooth AoA and AoD

Developers can turn to SoCs such as the EFR32BG22C222F352GN32-C from Silicon Labs to implement Bluetooth 5.2 networking and AoA and AoD. This SoC is part of the EFR32BG22 Wireless Gecko family that includes a 32-bit Arm® Cortex®-M33 core with 76.8 MHz maximum operating frequency plus a 2.4 GHz energy-efficient radio core with low active and sleep currents and an integrated power amplifier with up to 6-decibel meters (dBm) transmit (TX) power in a 4 × 4 × 0.85 millimeter (mm) QFN32 package (Figure 3). They include secure boot with root of trust and secure loader (RTSL). Additional security features include hardware cryptographic acceleration for AES128/256, SHA-1, SHA-2 (up to 256-bit), ECC (up to 256-bit), ECDSA, and ECDH, and a true random number generator (TRNG) compliant with NIST SP800-90 and AIS-31. Additionally, depending on the model, these SoCs have up to 512 kB of flash and 32 kB of RAM, and are available in 5 × 5 × 0.85 mm QFN40, and 4 × 4 × 0.30 mm TQFN32 packages, in addition to a QFN32.

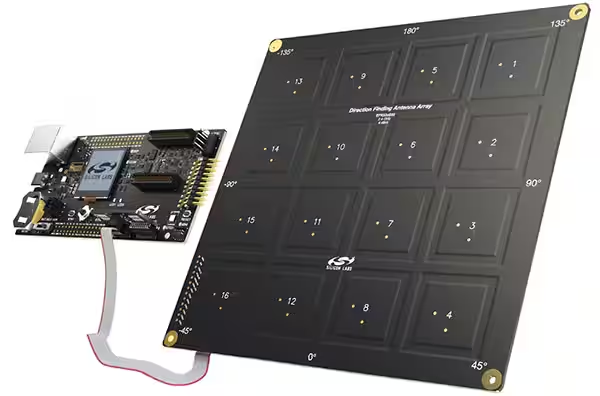

The BG22-RB4191A wireless pro kit includes a direction-finding radio board based on the 2.4 GHz EFR32BG22 Wireless Gecko SoC and an antenna array optimized for accurate direction finding that can speed development of Bluetooth 5.1-based RTLS applications using AoA and AoD protocols (Figure 4). The mainboard has several tools for easy evaluation and development of wireless applications, including:

- Onboard J-Link debugger for programming and debugging on the target device over Ethernet or USB

- Real-time current and voltage measurements using the advanced energy monitor

- Virtual COM port interface provides a serial port connection over Ethernet or USB

- Packet trace interface provides debug information about received and transmitted wireless data packets

Modules for Bluetooth AoA and AoD

u-blox offers Bluetooth modules with and without integrated antennas that support AoA and AoD. For applications that benefit from a module without an integrated antenna, designers can turn to the NINA-B41x series, such as the NINA-B411-01B, based on the Nordic Semiconductor nRF52833 IC (Figure 5). These modules include an integrated RF core and Arm® Cortex®-M4 with a floating point processor and operate in all Bluetooth 5.1 modes, including AoA and AoD. With an operating temperature range from -40 to +105 degrees Celsius (°C), these modules are well suited for RTLS applications in industrial environments. Furthermore, their input voltage range of 1.7 to 3.6 V makes them useful in single-cell battery-powered systems.

The NINA-B40x series from u-blox, such as the NINA-B406-00B, include an internal PCB trace antenna integrated into the 10 x 15 x 2.2 mm module PCB (Figure 6). NINA-B406 modules can deliver up to +8 dBm of output power. In addition to support for Bluetooth 5.1 modes, including AoA and AoD, these modules support 802.15.4 (Thread and Zigbee) and Nordic proprietary 2.4 GHz protocols, enabling designers to standardize on a single module for a wide range of IoT device designs.

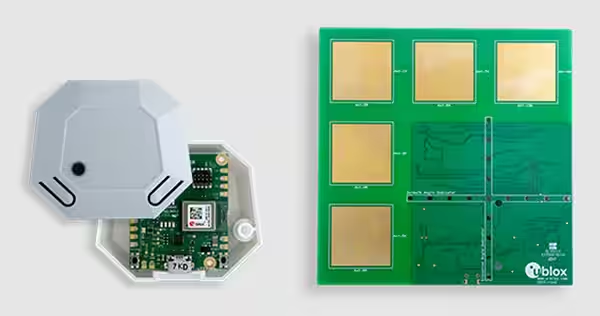

To speed time to market, designers can use the XPLR-AOA-1 explorer kit from u-blox that allows experimentation with the Bluetooth 5.1 direction-finding feature and support for AoA and AoD functions. This explorer kit includes a tag and an antenna board with a NINA-B411 Bluetooth LE module (Figure 7). The tag is built around a NINA-B406 Bluetooth module and includes software to send out Bluetooth 5.1 advertisement messages. The antenna board is designed to receive the messages and apply an angle calculation algorithm to determine the direction of the tag. The angles are calculated in two dimensions using the array of antennas on the board.

The flexibility of the XPLR-AOA-1 kit enables designers to explore a variety of applications, such as:

- Detecting if an object is approaching a door

- Enabling a camera to follow an asset moving in a room

- Tracking goods passing through a gate or past a specific position

- Avoiding collisions between robots or automated guided vehicles

In addition, a more complex positioning system can be created using several XPLR-AOA-1 kits and triangulating the directions from three or more antenna boards.

Summary

Bluetooth AoA and AoD can provide accurate and cost-effective RTLS implementations for Industry 4.0. Designers who can select from SoCs and modules that include the software needed to quickly implement the complex software required to deploy Bluetooth AoA and AoD. These SoCs and modules are optimized for low power consumption to support battery-powered location tags and are designed to operate in harsh industrial environments.