Asahi Kasei to Construct a Lithium-ion Battery Separator Plant in Canada

May 10, 2024

Asahi Kasei has announced that it will construct an integrated plant in Ontario, Canada for the base film manufacturing and coating of Hipore™ wet-process lithium-ion battery (LIB) separator1. In relation to this plant, Asahi Kasei has concluded a basic agreement with Honda Motor Co., Ltd. (Honda) and the two parties are currently studying joint investment.

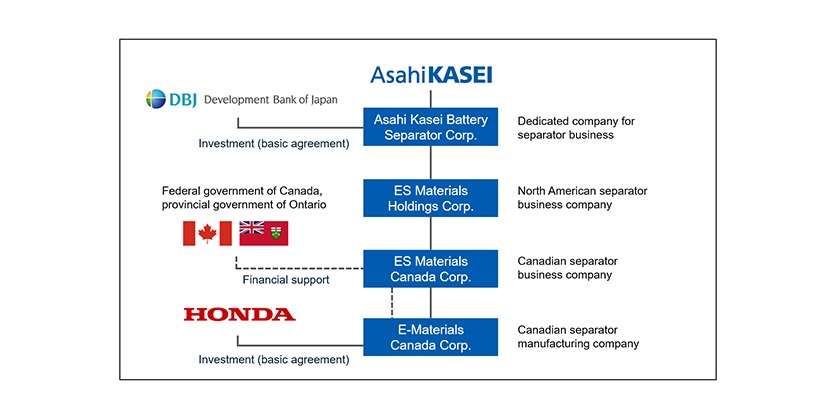

Also with regard to the Canadian plant, it has been agreed that Asahi Kasei Battery Separator Corp.2, which is scheduled to be established in October 2024, will receive funding from the Development Bank of Japan Inc. (DBJ) through the issuance of preferred shares. Furthermore, receipt of financial support from the federal government of Canada and the provincial government of Ontario regarding this investment is expected.

Outline of the Canadian investment (plant construction)

- Location: Ontario, Canada

- Plant overview: Integrated plant for the base film manufacturing and coating of Hipore™ lithium-ion battery separator

- Total investment amount: Approximately ¥180 billion

- Production capacity: Approximately 700 million m2 per year (as coated film)

- Start of operation: Commercial start-up scheduled in 2027

The necessary funds for this investment will be provided to ES Materials Canada Corp., the Canadian separator business company, and E-Materials Canada Corp., the local manufacturing company responsible for plant construction and manufacturing, through ES Materials Holdings Corp., the North American separator business company.

1. The separator business in Asahi Kasei

Asahi Kasei positions its Energy Storage related business as one of the “10 Growth Gears” (GG10) expected to drive future growth in its medium-term management plan for fiscal 2024, which is focused on the theme “Be a Trailblazer.” The core of its Energy Storage business is Hipore™ wet-process LIB separator, which has been leading technological innovation based on over 40 years of business history, and is currently expanding its sales in automotive applications in addition to consumer electronics applications.

To meet North American demand for battery separator for plug-in electric vehicles and to join North American LIB supply chains being established, in part as an effect of governmental clean energy policies, the decision was made to construct an LIB separator manufacturing plant in Ontario, Canada.

2. Basic agreement with Honda

Asahi Kasei and Honda have reached a basic agreement based on the shared understanding that it is essential to establish a supply chain for the stable supply of high-performance batteries for the North American plug-in electric vehicle market, which is expected to grow over the medium to long term. Studies are advancing for the establishment of a joint venture to manufacture Hipore™ separator for batteries installed in EVs made by Honda and other vehicle manufacturers for the North American market.

“To achieve carbon neutrality, Honda is targeting 100% of global sales from EVs and FCVs by 2040,” said Manabu Ozawa, Managing Executive Officer of Honda. “The separator is an extremely important component that contributes to higher performance and durability of batteries that are essential to EVs. We are very excited to partner with Asahi Kasei, having outstanding technological capability and broad expertise regarding separators. This will allow us to realize highly competitive EVs that can meet future growing demand in the North American market.”

“The Hipore™ business will play an important role in Asahi Kasei’s growth over the medium term,” added Hiroyoshi Matsuyama, Senior Executive Officer of Asahi Kasei. “Capturing market growth in North America will be essential for us. This partnership with Honda, having a rich track record in the North American automotive market and aggressively electrifying its vehicle lineup, allows us to make a meaningful contribution to improvement of LIB performance in light of anticipated growth in the electric vehicle market and the energy transition in North America.”

3. Financing from DBJ

In constructing a manufacturing plant for Hipore™ separator in Canada, it has been decided that Asahi Kasei Battery Separator Corp. will receive funding of ¥28 billion by issuing preferred shares to DBJ as a project that enhances the competitiveness of LIB separator business and strengthens LIB components supply capability.

4. Financial and Other Government Support

Asahi Kasei strives to achieve adequate production scale in accordance with market expansion while reducing investment risk, and expects to receive financial support from the federal government of Canada and the provincial government of Ontario, through its investment attraction agency, Invest Ontario, in addition to support under the September 2023 memorandum of understanding between Canada and Japan concerning battery supply chains.

- 1 A lithium-ion battery separator is a microporous membrane that provides a barrier between the positive and negative electrodes of a lithium-ion battery, allowing lithium ions to pass through while preventing short circuits.

- 2 Please refer to the press release “Transfer of lithium-ion battery separator business by corporate separation (simplified absorption-type separation) (107.9KB)” dated February 7, 2024.

Related Story

Honda Plans to Establish Comprehensive Electric Vehicle Value Chain in Ontario, Canada

Honda Motor Co., Ltd. has announced that it plans to build a comprehensive EV value chain in Canada with an approximate investment of CAD$15 billion, including investment by joint venture partners, to strengthen its EV supply system and capability to prepare for a future increase in EV demand in North America.

Honda has begun evaluating the requirements to build an innovative and environmentally responsible Honda EV plant and a stand-alone Honda EV battery plant in Alliston, Ontario. The proposed Honda EV value chain will also include a cathode active material and precursor (CAM/pCAM) processing plant through a joint venture partnership with POSCO Future M Co., Ltd. and a separator plant through a joint venture partnership with Asahi Kasei Corporation, with announcements to follow in their respective Ontario communities.