ANCA Marks Milestone Anniversary at IMTS with Debut of Next-Generation Technologies

September 27, 2024

ANCA’s legacy of innovation is shaping the future of technology for lower cost, higher quality cutting tool production

ANCA at IMTS not only celebrated five decades of innovation but 35 years of successful operations in the USA and exhibiting the first machine ever bought in the U.S., a refurbished TG4, was a nostalgic nod to ANCA’s technological journey. Against ANCA’s latest solutions, this was a striking visual display of the company’s journey – from early innovation to being a future-ready leader in the tool and cutter grinding industry.

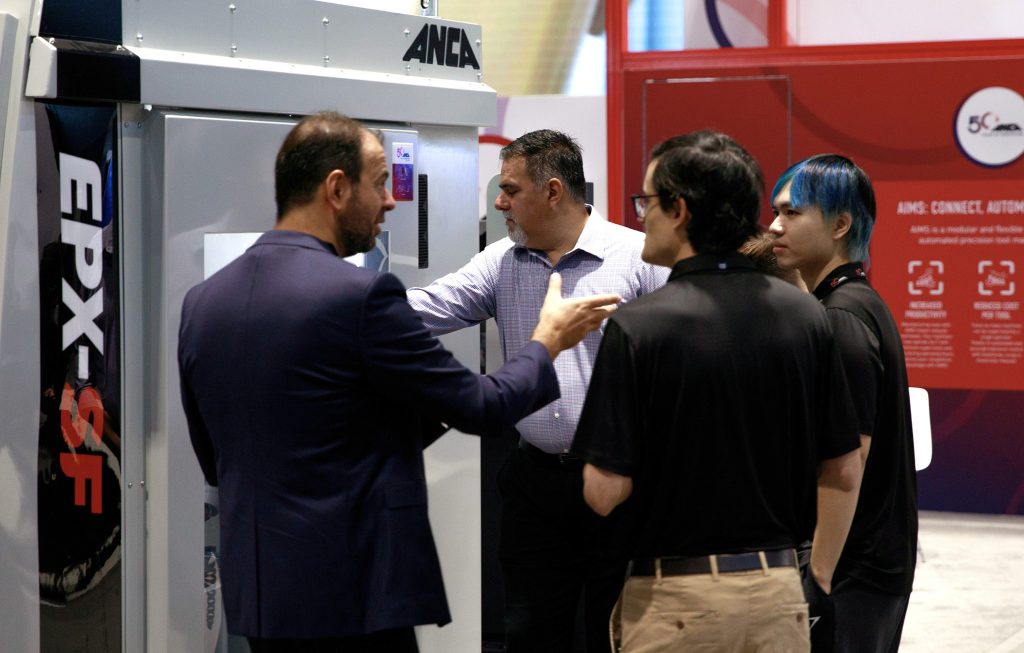

The North American debut of the EPX-SF, ANCA’s advanced stream finishing machine, became the centerpiece of attention. The EPX-SF’s technology offers consistent micro-cutting-edge preparation, controllable nano-smooth surface finishing, and seamless automation and it sparked widespread interest. Its unmatched ability to increase tool life, precision, workpiece quality and cost-effectiveness redefined expectations for the future of tool finishing.

Producing the highest performance cutting tools for lower cost with ANCA technology

ANCA CNC Machines General Manager, Edmund Boland said: “Given the competitive world that we are living in and the global market that we are challenged with…it is important that we allow our customers to get the best value out of our machines. So, our focus on lowest cost tools is critical and we have a number of technologies for this, AIMS being one of them.”

The manufacturing industry is embracing smarter, more connected solutions and seeking solutions partners. Revealed to the market in the Americas for the first time was AIMS Connect which is the production control of the ANCA Integrated Manufacturing System (AIMS) and enables the integration of different machines, offering full control over all processes and workflows. AIMS Connect’s smart job management and production control solves common challenges to increase productivity, reduce errors, and tackle labor challenges while increasing machine utilization and reducing the cost per tool.

Along with ANCA’s emerging technologies for reducing set up times of machines, software solutions to analyze the production output of machines, and how to optimize this to bring down the overall cost of production – smarter ways to produce quality tools for lower cost are meeting the industry demands for data-driven decision making, cost reduction and efficiency. ANCA is also formulating solutions for reducing the air consumption of machines which not only has a significant impact on machine running costs but also contributes to more sustainable manufacturing processes.

ANCA’s latest range of ULTRA machines are engineered with nanometer feedback resolution to dramatically improve surface finish and accuracy of cutting tools. With software developments, such as the new features of ToolRoom RN35 enabling complex geometries, customers have the flexibility to design high performance, higher accuracy and, if needed, custom cutting tools with specific applications. High performance tools produced with ANCA ULTRA technology deliver batch consistency from tool number one to one thousand.

A celebration of industry

ANCA’s 50 years in the grinding industry is thanks to the partnerships and loyal customers that have accompanied its journey. The 50th anniversary milestone was celebrated with partners, customers, and industry at a gala dinner during IMTS.

IMTS also provided the stage for the announcement of the winners of the ANCA Tool of the Year and Female Machinist awards which are consistently supported by industry and partners. The 2024 winners Werkzeugschleiferei Krämer GmbH (Made on ANCA) and XGE (Virtual Tool) once again demonstrated the possibilities of creative design, precision and craftmanship with today’s technologies. Witnessing Krämer, a smaller company take out a competition at a global level was a dream come true for taking precision to the world stage.

Stephanie Chrystal from Sandvik Coromant USA was awarded the ANCA Female Machinist of the Year for her exceptional problem-solving, leadership in expanding and training her team, and her ability to deliver outstanding results under pressure.

Industry collaboration is pushing innovation further and offering unique solutions to customer challenges. ANCA’s new partnership with Tetralytix introduces sophisticated digital interface solutions that reduce tool design and development time with Toolyzer. This partnership empowers manufacturers with the most advanced and powerful software tools available.

More Information

For further information, please contact:

Amanda Bakun, Marketing & Communications Manager – Americas, 248-497-1168, or amanda.bakun@anca.com

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil, Korea and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

Related Story

ANCA Celebrates 50th Anniversary and Contributions to the High-Precision Tool-Cutting Industry

ANCA was founded by Pat Boland, an Electrical Engineer, and Pat McCluskey, an Industrial Electronics Engineer in 1974, in Melbourne Australia. For 50 years, the company expanded globally. Today they employ over 1200 people worldwide and serve customers in more than 46 countries. Pat Boland, co-founder, discusses this journey and some of the innovations they have contributed to the high-precision tool-cutting industry.