ABB Wins Global Consulting Firm’s Company of the Year Award for Excellence in Emissions Monitoring

January 8, 2024

The award recognizes ABB’s commitment to support industrial decarbonization through a best-in-class portfolio of intelligent instrumentation and gas analyzers

- ABB has received the prestigious award from Frost & Sullivan for vision, innovation and technical expertise in emissions monitoring and methane gas leak detection

- The award recognizes ABB’s commitment to support industrial decarbonization through a best-in-class portfolio of intelligent instrumentation and gas analyzers

- ABB’s history of innovation in emissions monitoring is cited as shaping industry trends and supporting customers across a complex landscape of stringent emissions regulations

ABB has earned this year’s Frost & Sullivan Company of the Year Award in the global emissions monitoring systems industry. Frost & Sullivan’s global team of Growth Pipeline experts chose ABB based on its visionary understanding of future world challenges, the deployment of best practices and strategic analytics, as well as innovation and technical expertise in emissions monitoring and methane gas leak detection. According to Frost & Sullivan, ABB is shaping industry trends and supporting customers across a complex landscape of stringent emissions regulations.

“There has been a long-term commitment from ABB to the development of multiple innovative emissions monitoring and gas leak technologies that serve the broadest industry sectors worldwide,” said Jean-René Roy, Global Business Line Manager, ABB Measurement & Analytics. “It is fantastic that Frost & Sullivan has recognized our collective achievement and leading technology through this award, and I would like to thank my team for their continued dedication to the cause.”

Jean-René Roy, Global Business Line Manager, ABB Measurement & Analytics

The lasting impact of greenhouse gas emissions and more stringent regulations means that carbon-intensive industries are increasingly demanding emissions management and reduction solutions. For example, the EU recently announced a first-ever regulation to curb methane emissions from energy companies[1], while in the United States, current regulations require oil & gas companies to accurately measure methane emissions.[2]

According to Frost & Sullivan, ABB’s high-quality, digitally enabled products and solutions for measuring processes and greenhouse gas emissions, detecting gas leaks, and optimizing production drive cost-effective compliance and long-term efficiency.

ABB’s extensive instrumentation and gas analyzer portfolio includes continuous emissions monitoring systems (CEMS) used in power generation, chemicals and refineries, waste incineration, co-combustion, marine and other applications. The portfolio also comprises the ABB Ability™ Natural Gas Leak Detection Solutions, a comprehensive suite which detects and maps gas leaks with unrivalled accuracy.

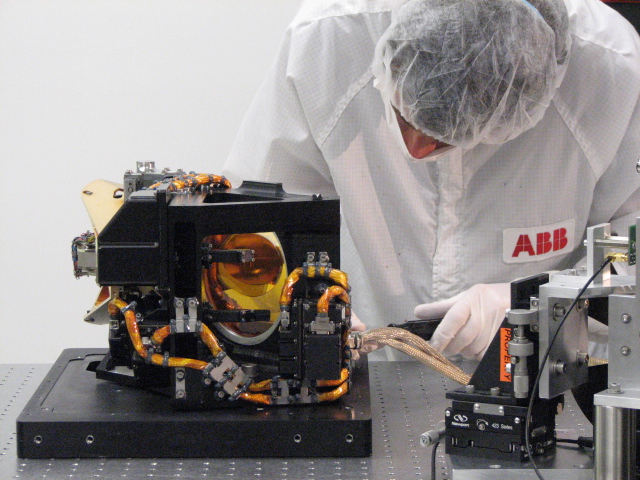

In addition, ABB has been at the forefront of greenhouse gas sensing from space for over two decades. Collaborating with major space agencies worldwide has given the company a competitive edge. ABB applies its vast expertise acquired in high-profile government space missions to the private sector to strategically modernize the area and continue to make advancements in the space industry.

With the aim of achieving collective, coordinated action on a global scale, the US Department of Energy recently awarded ABB a grant for the development of a single repository platform that will aggregate, analyze, and visualize methane data from multiple sources for the first time. The vital platform will allow for a significant reduction of methane emissions, pollution, and waste, enabling substantial progress on climate change targets.

ABB’s emissions monitoring technology is also used to tackle the massive environmental problem of millions of leaking orphan oil and gas wells across the United States. The company’s high-sensitivity analyzers using OA-ICOS™ laser-based technology can detect methane emissions from decommissioned wells down to one part per billion.

ABB’s Process Automation business automates, electrifies, and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water, and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps customers in process, hybrid and maritime industries improve performance and safety of operations, enabling a more sustainable and resource-efficient future. go.abb/processautomation

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered, and operated. Building on more than 140 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation. www.abb.com

[1] https://ec.europa.eu/commission/presscorner/detail/en/IP_23_5776

[2] https://www.iea.org/reports/global-methane-tracker-2023/the-case-for-methane-policy-and-regulation

Related Story

ABB Factory Celebrates 50 Years at the Forefront of Sustainable Analytical Technologies

ABB is marking the 50th anniversary of its Quebec Measurement & Analytics factory which today manufactures market-leading products for industrial analytical measurement and is one of the largest suppliers of optical sensors for detecting greenhouse gas emissions from space.