ABB To Push Boundaries of Methane Emissions Monitoring with Funding from U.S. Department of Energy

October 17, 2023

- ABB has received significant funding from the U.S. Department of Energy to design an Integrated Methane Monitoring Platform, a single repository that will aggregate, analyze, and visualize data from multiple sources in the United States for the first time

- With a total value of $1 million, the project will enable continuous methane emissions monitoring, mapping, localization and quantification across the entire natural gas supply chain and infrastructure in the country

- The comprehensive platform will help the United States significantly reduce methane emissions, pollution and waste, and reach city, state, and national sustainability targets

ABB has received significant funding from the U.S. Department of Energy (DOE) Office of Fossil Energy and Carbon Management and the National Energy Technology Laboratory (NETL) to design an Integrated Methane Monitoring Platform that will advance the development of new and innovative methane measurement, monitoring and mitigation technologies in the United States. The total value of the project is $1 million, of which DOE will contribute 80 percent, with ABB contributing the remaining 20 percent.

Today, methane emissions are recorded by academic researchers, industry and technology providers using many different methodologies and over various spatial scales and temporal intervals. The various methods yield data with vastly different performance characteristics and quality metrics.

At one end of the spectrum, sensors monitor methane emissions near natural gas producing regions quasi-continuously and report every 15 minutes with low accuracy, while at the other end of the spectrum, sensors mounted on aircraft and satellites patrol over large regions weekly or monthly looking for ‘super-emitters’.

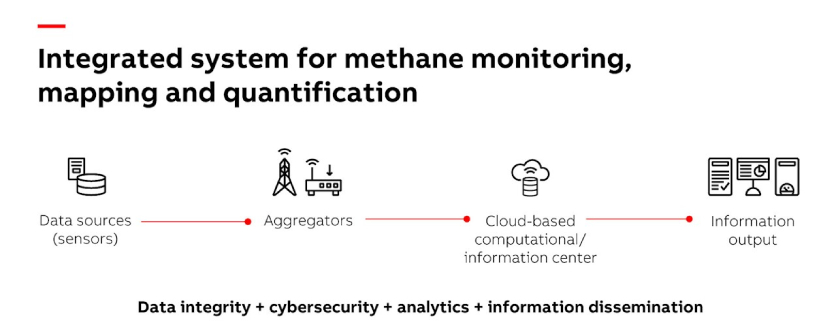

Data is generally recorded, analyzed, and visualized separately. A single repository of data does not yet exist to handle data from multiple sources. With DOE’s funding, ABB will develop a detailed engineering plan for the first comprehensive, US-focused platform that will detect, quantify, and ultimately help to reduce methane emissions across the entire natural gas supply chain and infrastructure of the United States.

“As a global leader in methane sensing technology, we have a big responsibility in this field. The Department of Energy funding will help us push the boundaries of emissions monitoring. The result of this work will be very tangible and can lead to a significant reduction of methane emissions throughout the United States, helping achieve sustainability targets,” said Jean-René Roy, Global Business Line Manager, ABB.

Jean-René Roy, Global Business Line Manager, ABB

“We are happy to fund the design of ABB’s Integrated Methane Monitoring Platform as part of the project selection under the Department of Energy’s Innovative Methane Measurement, Monitoring and Mitigation Technologies (IM4 Technologies) funding opportunity,” said Timothy Reinhardt, Director, Division of Methane Mitigation Technologies, DOE’s Office of Fossil Energy and Carbon Management. “We believe that the project’s scope fits in well with our goal to advance the development of new and innovative technologies to reduce and ultimately eliminate methane emissions from hydrocarbon infrastructure.”

Timothy Reinhardt, Director, Division of Methane Mitigation Technologies, DOE’s Office of Fossil Energy and Carbon Management

The platform will:

- Aggregate measurements of methane emissions recorded through different methodologies over various temporal and spatial scales.

- Analyze data using advanced Big Data analytics.

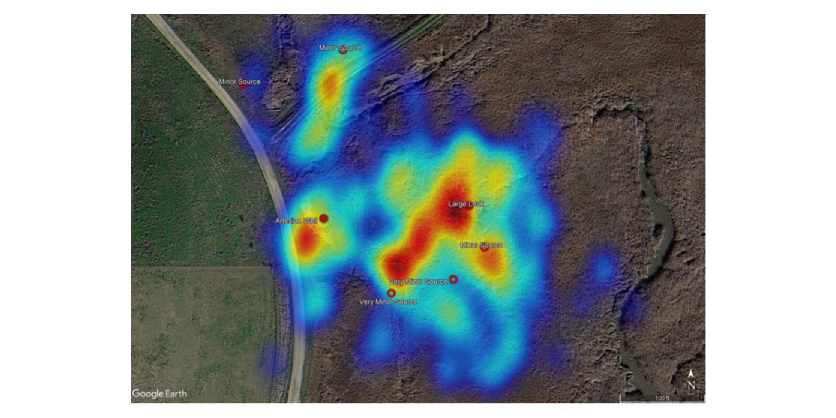

- Visualize data and present detailed information on geospatial maps.

- Allow stakeholders including industry, academics, government policy makers and compliance entities to identify and fix issues quickly and to quantify trends over short- and long- time scales (for example, minutes to months) and over small and large areas (for example, streets to states).

ABB will build on its deep knowledge of measurement science, data source aggregation, digital technologies, and advanced analytics to create the comprehensive engineering, design, construction, deployment, and operating plan.

The system will enable rapid identification, localization, and characterization of ‘super-emitters’, intermittent sources, as well as chronic, persistent, smaller emission sources, and enable stakeholders to rapidly address and mitigate unwanted emissions.

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps customers in process, hybrid and maritime industries improve performance and safety of operations, enabling a more sustainable and resource-efficient future. go.abb/processautomation

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered, and operated. Building on more than 140 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation. www.abb.com

Related Story

Methane Leak Detected from Space in the UK Successfully Mitigated

Methane leaking from a faulty pipe in Cheltenham, Gloucestershire, has been observed by GHGSat satellites orbiting 500km overhead. The discovery, by NCEO researchers at the University of Leeds, using data from GHGSat, marks the first time a UK methane emission has been seen from space and mitigated.