ABB Opens Global Innovation and Training Campus for Machine Automation at B&R In Austria

August 9, 2022

- New campus serves as ABB global R&D center for machine and factory automation, AI and software solutions

- Global innovation hub expanded significantly to host machine builders, manufacturers, start-ups, research, and educational institutions

ABB opened its new global innovation and training campus at the headquarters of B&R in Eggelsberg, Austria, its global center for machine and factory automation. The new campus will create up to 1,000 additional high-tech jobs and includes world-class research and development laboratories, as well as global training facilities for up to 4,000 people per year in collaboration with universities.

(1/2) The new campus is one of the largest sites for integrated production, research, and training in central Europe, with currently around 2,400 employees.

ABB invested EUR 100 million in the expansion of the B&R headquarters.

Campus innovations around artificial intelligence and machine and factory automation will play an essential role in unlocking the potential of future industrial production – in sectors such as electronics, e-mobility, food and beverage, recycling, logistics, or agriculture. They will increase productivity and flexibility, helping customers become more sustainable and produce closer to their end markets.

ABB CEO Björn Rosengren said: “Innovation has been in ABB’s DNA for more than 130 years and our division, B&R, is a true innovation hot-spot for the transformation towards more automated manufacturing. The official opening of this campus is a proud moment for our ABB as we create highly skilled jobs while shaping the machines and factories of the future together with our customers.”

A hub for integrated production, research, and training in central Europe

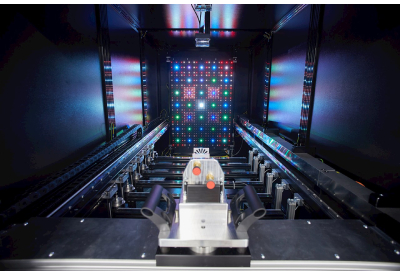

The new campus expands the total area of B&R’s headquarters to more than 100,000 m², making B&R one of the largest sites for integrated production, research, and training in central Europe, with currently around 2,400 employees. The expansion will also free up space which will serve as additional production capacity to meet increasing demand for B&R products.

(2/2) The new campus is one of the largest sites for integrated production, research, and training in central Europe, with currently around 2,400 employees.

Austria’s Chancellor Karl Nehammer thanked ABB for an important initiative: “Investments in our business location are always also investments in the future of Austria. The corona pandemic, disruptions in global supply chains and now the war in Ukraine clearly remind us that we need to become more independent if we want to be better prepared for future challenges. I am therefore pleased that ABB is taking an important step in bringing manufacturing back home with the opening of its new innovation and training campus. The new campus will not only be a driver for digitalization and automation, but also will create jobs and contribute to prosperity in Austria.”

In a rapidly changing world, facilities such as the new ABB global campus are of utmost importance to Austria’s role in the global economy and generate growth as a center for innovation and investment. The ever-growing digitalization and automation of our industries will be key for the re-industrialization of Europe and for bringing manufacturing back to Austria. By homeshoring industry, we are creating new jobs, securing Europe’s supply chain, and seizing the opportunities for a more sustainable future.”

Sami Atiya, President of ABB’s Robotics & Discrete Automation business area, added,

“This is a decade of transformation towards robotics and automation as our customers respond to global labor and supply shortages, accelerating consumer demand for personalized products and the need to operate more sustainably. ABB’s new campus will serve as a customer collaboration center where we work with customers around the globe, helping them to respond to these trends and supporting B&R in becoming the partner of choice for the world’s most ambitious industrial automation projects.”

(1/3) At the campus B&R will closely collaborate with international customers, companies, and start-ups from across the region, as well as research and educational institutions to co-develop automation solutions and train the talents needed for the factories of the future.

According to ABB research, 8 out of 10 companies in Europe and the U.S. are planning to further automate and 7 out of 10 to near- or reshore their production. The global addressable market volume for machine and factory automation is currently estimated at $20 billion p.a. and is expected to increase to $31 billion p.a. by the year 2030.

With the acquisition of B&R in 2017, ABB is the only company offering industrial automation customers the entire range of integrated hardware and software solutions around control, actuation, robotics, sensing as well as analytics and electrification.

Open innovation and education hub to develop and train together

The ABB innovation and training campus will serve as an open innovation hub, where B&R will closely collaborate with international customers, companies, and start-ups from across the region, as well as research and educational institutions to co-develop automation solutions and train the talents needed for the factories of the future.

“We are currently experiencing a record number of job vacancies in Austria. At the same time, more people are currently employed than ever before. This makes it all the more important to counteract the skills gap that can be felt in Europe in order to keep pace with the digital transformation and seize the chances it provides. B&R’s new campus with its dual training program is an important example of how to bring European manufacturing companies to the forefront of the world with skilling initiatives and innovation to successfully meet current economic and societal challenges,” said Austria’s Minister of Labor Martin Kocher.

(2/3) At the campus B&R will closely collaborate with international customers, companies, and start-ups from across the region, as well as research and educational institutions to co-develop automation solutions and train the talents needed for the factories of the future.

Jörg Theis, President of B&R, said:

“Education will be given highest priority at the campus. Our Automation Academy will offer inspiration and training opportunities for up to 4,000 students, apprentices, customers’ experts, and employees from all around the world every year.” Theis added that B&R plans to offer dual education at the university level in collaboration with higher education institutions.

B&R unveils new brand identity

With the new campus, B&R has also unveiled a new brand identity creating a visual connection between B&R and ABB. “Our new visual design underscores ABB’s strong commitment to B&R as a category brand and shows the strength of B&R and ABB as we grow together and work together. Being part of that bigger family creates many new possibilities for every employee to proactively shape their career,” said Theis.

Sustainable campus with one of the largest self-consumption PV systems in Austria

As part of its sustainability strategy 2030, ABB expects to achieve carbon neutrality across its own operations by the end of the decade. At B&R, ABB has installed one of the largest self-consumption photovoltaic (PV) systems in Austria. Additional PV modules on the campus will now increase the total output to 1.8 MW. The self-consumption rate is approximately 98 percent.

More than 110 years of history in the Austrian industry

ABB has operated in Austria for more than 110 years and has a proud history in the Austrian industry – from electrification to railways and powering ski-lifts to robotics and process automation. The acquisition of B&R in 2017 made ABB the largest supplier of industrial automation in Austria.

(3/3) At the campus B&R will closely collaborate with international customers, companies, and start-ups from across the region, as well as research and educational institutions to co-develop automation solutions and train the talents needed for the factories of the future.

Related Story

Ultra-Low Harmonic Drives for Increased Efficiency and Reliability of Processes and Systems

Variable speed drives can save substantial amounts of energy by adjusting motor speed to the application need. But it is crucial to evaluate the effect of VSDs on the power system before making the final choice, because some variable speed technologies can have an adverse impact on the power quality in the network, resulting in lower system efficiency and reliability, and higher project costs.