Bossard Brings Industry 5.0 Fastening Technology to IMTS 2024 in Chicago

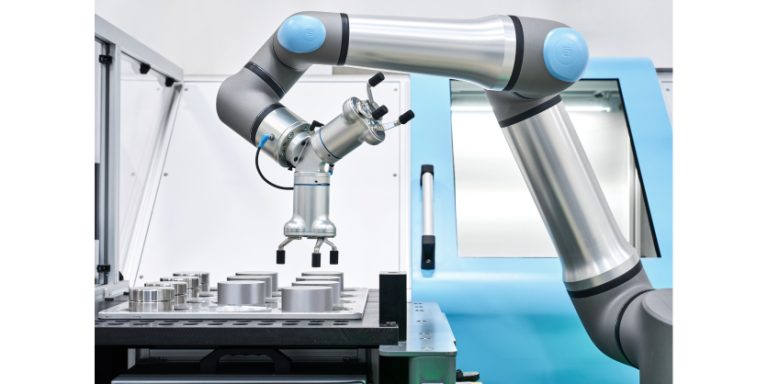

August 1, 2024 Bossard Inc., a leader in industrial fastening and assembly technology solutions, announces a live demonstration of its innovative fastening technology at the 2024 International Manufacturing Technology Show (IMTS). Bossard’s Fastening Innovations: Bossard demonstrates their Ultrasonic Measuring Equipment and Junker’s Vibration Testing Machine at IMTS. This innovative technology addresses critical concerns for manufacturers…