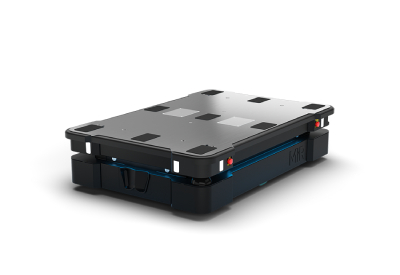

AGILOX Introduces New ODM Robot

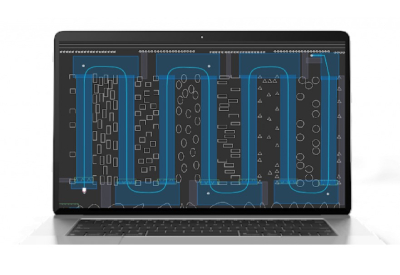

AGILOX expands its product portfolio with an intelligent dolly mover January 12, 2023 After the ONE and the OCF, now comes the ODM, an intelligent ODM robot. AGILOX North America, a leading manufacturer of automated material handling solutions, is adding an autonomous dolly mover to its range of intelligent transport systems controlled by its proprietary…