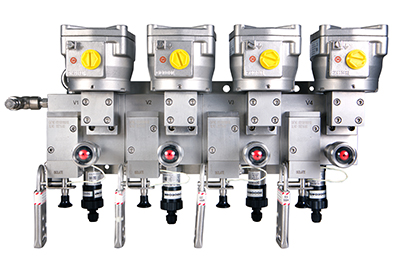

Slim 5-Axis Vise With Tool-Free Jaw Quick-Change and Active Jaw Pull-Down for Precise Machining of the Sixth Side

If you think that the innovation potential of stationary clamping system is already ex-hausted, you should have a look at SCHUNK: The specialist for gripping systems and clamping technology continues its success story with the 5-axis vise KONTEC KSX-C2 and provides new impulses for high-precision 6-sided machining.