New End-of-Arm Ecosystem From Zimmer Group and Schmalz

April 15, 2021

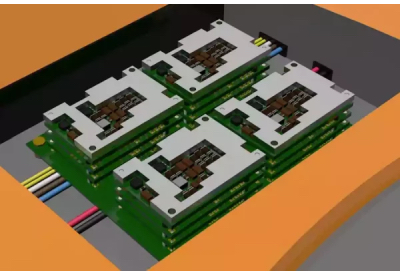

“It’s a MATCH – that fits” – is what can be said about the first cooperation project between the two handling technology specialists Zimmer Group and J. Schmalz GmbH, and that is also the name of the joint product. MATCH is a future-proof multifunctional end-of-arm platform. Equipped with an extensive function portfolio and universal communication interfaces is MATCH compatible with every common lightweight robot and conventional robots on the market. With the MATCH platform, the two technology leaders in their respective fields – Zimmer Group with its focus on mechanical grippers, Schmalz with vacuum-based technologies – bring together the best of two gripping worlds. “This collaboration has resulted in something unique: a modular system with which customers can flexibly solve a wide variety of requirements and applications in robotics,” explains Achim Gauß, Managing Director of the Zimmer Group. “In addition to their concentrated solution expertise, both companies offer a worldwide sales network for support and service,” adds Dr Kurt Schmalz, managing partner of J. Schmalz GmbH.

Multiple system – numerous areas of application

Whether mobile, collaborative robotics or fully automated applications: With just one flexible system, the user has access to an almost unlimited range of applications from production and assembly to warehouse logistics, shipping or laboratory automation. The installation of MATCH is extremely simple. The system can be easily mounted and set up on the robot flange in just a few steps. Parameterisation is intuitive and very easy thanks to support from the shared digital services. The quick-change system has various interfaces. In addition to a compatible mechanical interface, a pneumatic/vacuum connection and electrical interfaces are available. This technological openness makes it possible to open up many different robot types with a wide variety of end effectors.

Manual and automated quick-change function

Due to the compact quick-change module, a component can be changed quickly and easily in two ways. In addition to an automated change in a storage station or the so-called gripper station, a manual change is also possible within seconds. Thanks to the ergonomic click system – integrated on the end effector to be changed – a manual change is possible with only one hand and at the same time prevents the exchange module from falling down.

Smart Ecosystem – intuitive software

The Zimmer Group and Schmalz have their own ecosystem with which the user can use numerous digital services. In addition to the communication module SCM (Master Gateway), the intuitive setup software guideZ is available to the user for further configuration of the gripper, as well as the Schmalz Connect Suite for the diagnosis of IO-Link devices in the cloud. MATCH guarantees full support and process control – from commissioning to ongoing operation and process monitoring.

The advantages of MATCH at a glance:

- – One system for lightweight robots, cobots and conventional robots

- – Automated changing in the fixture

- – Manual change with Easy-Click function

- – Wide variety of end effectors

- – Compatibility and flexibility – the main handling technologies (vacuum and mechanical gripping) combined

- – Innovative digital ecosystem

- – Long service life, even in automated continuous operation