Bosch Rexroth: Lubricated for Life

February 17, 2021

The electromechanical cylinders EMC from Bosch Rexroth now have much longer lubrication intervals. Many applications even benefit from lifelong lubrication, which makes the EMC cylinders in these solutions maintenance-free. The high-precision linear motion technology with basic factory lubrication offers the manufacturers of machine tools as well as handling and automation solutions significant competitive advantages.

Maintenance-free linear motion technology increases productivity and reduces the overall costs. The electromechanical cylinders EMC have been improved on an ongoing basis. With the latest generation, Bosch Rexroth has put in place optimum conditions for achieving these goals.

The EMC cylinders with the “Lubricated For Life” option achieve a nominal service life of up to 15,000 km with the basic factory lubrication.

Design engineers can easily find out whether lifelong lubrication is possible for a planned application using Bosch Rexroth’s LinSelect selection and design tool. The EMC which can be designed in just a few minutes can then be transferred to the online configurator, fully configured and then ordered. The corresponding CAD data are generated and provided automatically.

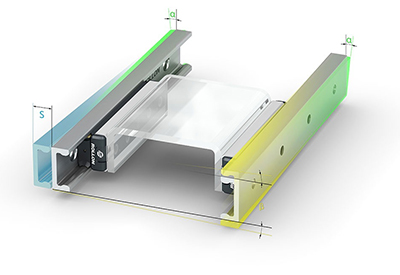

The electromechanical cylinders EMC combine anodized aluminum profiles in standard ISO sizes with an integrated ball screw assembly to form a ready-to-install solution. Thanks to advanced production processes and extensive testing with lubricants, Bosch Rexroth has continually increased the lubrication intervals and has now achieved lifelong lubrication. During wide-ranging stress and endurance tests, the new values were validated under various conditions of use.

Bosch Rexroth’s EMC range comprises seven finely scaled sizes. The largest version, the EMC100-XC-2, provides thrust forces of up to 56 kN. Bosch Rexroth also provides a wide range of servo motors and drive controllers tailored to the various sizes. An optional force sensor allows decentralized process control via a higher-level control system.