Visualize the Wireless Networks of Your AGV and AMR Systems with MOXA Solutions

April 16, 2025

Ensuring Reliable Wireless Uptime for AGV and AMR Systems

As the demand for automated material handling (AMH) systems continues to rise—driven by the expansion of e-commerce and smart factories—the importance of stable wireless networks in autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) has never been more significant. With AMRs projected to grow at a CAGR of 43%* and AGVs at 24%* from 2022 to 2027, uninterrupted operations for these mission-critical systems are paramount.

AGV and AMR systems are mission-critical assets, so smooth operations are essential. Unstable wireless signals can disrupt AMH systems, underscoring the need for dependable solutions with seamless connectivity and easy-to-manage networks.

Key Challenges for Wireless Networks

Hard to Manage

Unlike wired systems, wireless networks are invisible and prone to disruptions caused by multiple external factors. This makes identifying issues challenging and often leads to discovering problems only after operations are impacted. Troubleshooting and root cause analysis are time-consuming, resulting in avoidable downtime. These issues together make managing wireless connections challenging.

Unreliable Connectivity

AGVs and AMR shuttles operate continuously within warehouses, requiring client devices mounted on these mobile systems to transition seamlessly between access points (APs) without interruptions. These devices must also support industrial protocol communication over wireless networks to facilitate interactions between connected PLCs and the remote controller. Furthermore, Wi-Fi configurations are often complex, time-intensive, and susceptible to mistakes.

Limited Space and Interference

The design of AMR and AGV systems often requires accommodating limited installation space. Consequently, the motors powering the vehicles and shuttles frequently share a power source with the communication devices. As a result, wireless devices installed on AGV or AMR structures must be capable of handling interference from nearby equipment. Additionally, they need to endure the vibrations caused by the vehicles’ continuous movement.

Why Moxa Wireless Solutions Are Ideal for AGV and AMR Systems

Simplified Network Management

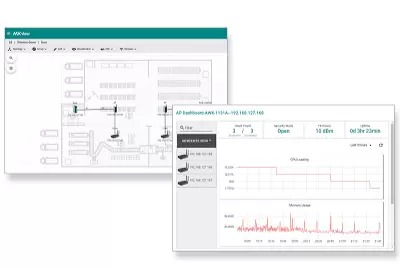

Moxa’s MXview Wireless offers an intuitive visual interface, allowing real-time monitoring of wireless network topology and performance. Automatic alerts for anomalies and playback of roaming history simplify troubleshooting and ensure quicker issue resolution to minimize downtime.

Reliable Mobile Operations

To maintain uninterrupted AGV operations, the AWK Series AP/bridge/clients are equipped with Turbo Roaming technology, enabling handoffs at the millisecond level. Additionally, the AWK Series supports the unique MAC Clone function, allowing seamless PROFINET communication over wireless networks. Built with security in mind, these devices adhere to the IEC 62443-4-2 industrial cybersecurity standard and include advanced WPA3 encryption. This ensures the AWK Series provides secure, future-ready wireless solutions that safeguard sensitive data and comply with secure network design requirements.

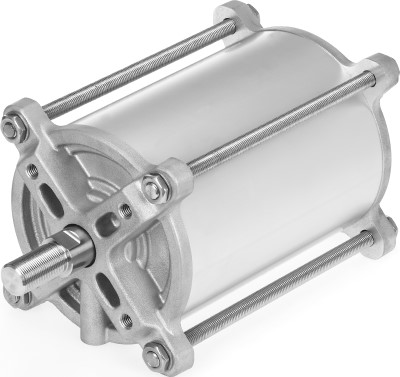

Compact but Rugged

The AWK Series wireless clients, certified for industrial EMC standards, combine a compact design with robust performance. They are equipped with built-in antenna isolation to guard against interference, ensuring reliable operation. These devices are subjected to rigorous testing and are built to endure extreme vibration, which makes them ideal for demanding environments. Additionally, with an extended operating temperature range of -40 to 75°C, the AWK Series is perfectly suited for deployment in cold-storage warehouses.

Reliable Wireless Solutions for Your AGV and AMR Systems

Find the Ideal Network Management Software

Unlock seamless management with the MXview One add-on module, tailored for wireless networks:

- Instantly visualize Wi-Fi connections and network status

- Replay roaming history to pinpoint the root causes.

- Minimize downtime with real-time alerts for faster recovery. Streamline operations with reliable wireless management!

Major Challenges for Wireless Networks

| Moxa Solutions | AWK-1161A Series AP  | AWK-1165A Series AP  | AWK-1161C Series Client  | AWK-1165C Series Client  | AWK-3252A Series AP/Client  | AWK-4252A Series AP/Client  | AWK-1151C Series Client  |

| Standards | |||||||

| Wi-Fi Standard | Wi-Fi 6 (802.11ax) | Wi-Fi 5 (802.11ac Wave 2) | |||||

| Wireless Security | WPA3, Security features based on IEC 62443-4-2 standard | WPA3, IEC 62443-4-2 (certified) | |||||

| Data Rates | 574 Mbps (2.4 GHz) / 1,201 Mbps (5 GHz | 400 Mbps (2.4 GHz) / 867 Mbps (5 GHz) | |||||

| Network Management | |||||||

| MXview |  |  |  |  |  |  |  |

| Mobile Operations | |||||||

| MAC Clone |  |  |  |  |  |  |  |

| Roaming Ability |  |  |  |  |  |  |  |

| NAT |  |  |  |  |  |  |  |

| Compact but Rugged | |||||||

| Interface | 1 x Ethernet | 5 x Ethernet | 1 x Ethernet | 5 x Ethernet | 2 x Ethernet (1 x PoE+) | 2 x Ethernet (1 x PoE+) | 1 x Ethernet |

| Anti-vibration |  |  |  |  |  |  |  |

| Industrial EMC & Antenna Isolation |  |  |  |  |  |  |  |

| Major Challenges for Wireless Networks -40 to 75 Operating Temperature Range |  |  |  |  |  |  |  |

| Ingress Protection | IP30 | IP30 | IP30 | IP30 | IP30 | IP68 | IP30 |

More Information

Related Story

Moxa Unveils New-Generation x86 Industrial Computers to Top Up Data Connectivity at Industrial Edge

Moxa Inc., a leader in industrial communications and networking, officially announced the launch of a new family of x86 industrial computers (IPCs) with exceptional reliability, adaptability, and longevity to address the increasing demands of data connectivity and real-time processing of large volumes of sensor and device data at the industrial edge. The industrial sector is rapidly embracing digital transformation with increased awareness about resource optimization, which is driving up the demand for reliable x86 IPCs as edge devices to interface with the industrial IoT application platforms and accelerate the deployment of Industry 4.0-enabled solutions.