Seamless Automation Removes Technological Boundaries

April 16, 2025

Consistency is what distinguishes Festo – in terms of technologies and the value creation process

“No matter what movement task customers approach Festo with, we can solve it. We are the only supplier to combine electrical and pneumatic automation technology that fits together seamlessly,” explains Gerhard Borho, Member of the Executive Board for IT and Digitalization at Festo. In doing so, he emphasizes the core of the “Seamless Automation” approach at Festo. Seamless – this applies to Festo from a technological point of view, but also across all phases of the customer’s value creation process.

Festo is the only supplier in the industry to offer a broad portfolio of pneumatic and electrical automation technology as well as digitalization and AI solutions from a single source. Thanks to the open system architecture, the products and technologies can be connected intelligently and thus easily with each other. Customers benefit from a great deal of flexibility, because Festo provides them with the solution that best suits their individual movement task – regardless of technology. Other advantages are the open system architecture for controlling electrical and pneumatic systems in one solution. This ensures a seamless and simple connection to the control architecture of the customers’ machines and systems and saves them up to 70% in development time.

The prerequisite for being able to offer users this technological flexibility is a broad portfolio – also in terms of electrical automation. Here, too, consistency is the top priority. It is used for axes, motors, servo drive controllers, motion controllers and the appropriate automation software AX Controls, right through to the integration of all data in IoT environments and evaluation with standardized AI apps.

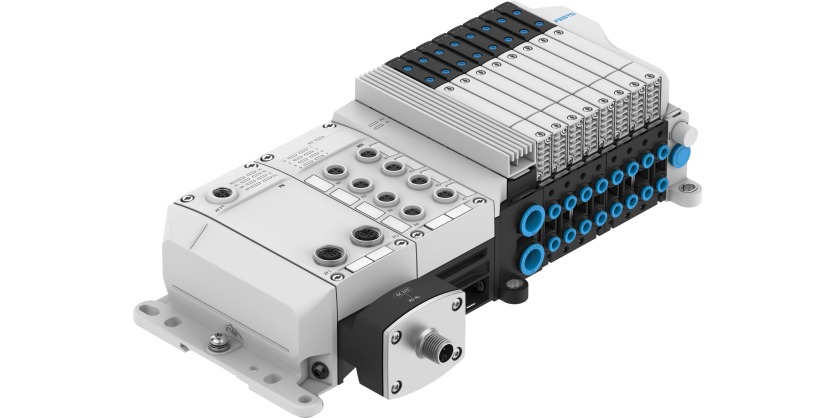

One example of seamless automation at Festo is the VTUX valve terminal in combination with the CPX-AP-A remote I/O system: This creates the connection between pneumatic and electrical automation. The combination enables the easy connection of pneumatics to AI solutions and allows smart and innovative functions.

Consistency of value-added processes

The topic of consistency affects not only products and technologies, but all phases of the value creation process at the customer. “We support our customers from the idea to the operation of the machine throughout the entire value creation process,” explains Frank Notz, Chief Sales Officer at Festo.

New software solutions are now being added with which Festo is taking its customers by the hand along the entire value chain. With the personalised dashboard “MyFesto” on the Festo websites, for example, customers have a central overview of their current offers and service enquiries and can access all data on Festo products from their projects on “MyFesto Projects”.

In the future, users will have an even easier time at Festo: With the “System Configurator”, they will have a central entry point into the entire world of Festo engineering tools: Customers can use it to design, select, dimension and configure their individual automation systems as a complete machine topology: They can configure specific components or entire load cases – from PLCs to drive controllers and remote I/Os in the AP network to IO-Link devices. This seamless integration enables efficient collaboration between different functions in the company by allowing design engineers and buyers to access the same data.

Seamless collaboration

Consistent data storage via “MyFesto Projects” makes it possible to import design data and control parameters directly into the Festo Automation Suite. This greatly simplifies the commissioning of the mechatronic subsystems. It also significantly reduces the time to first movement and facilitates the transition from planning to implementation. The Festo Automation Suite also provides function modules and device description files to seamlessly integrate the subsystems into the PLCs of all common manufacturers, which significantly improves connectivity.

Comprehensive automation portfolio

Today’s users have to combine control and motion technologies, AI, data integration and predictive maintenance in short development cycles. Festo is enabling more and more motion solutions via Festo AX Controls. It supports users with many software modules, including the Festo AX OS operating system, the Festo AX Motion control software and the Festo AX Machine Visualization software.

This open architecture enables flexible development of individual solutions and seamless integration of existing systems. Fields of application can be developed from classic motion controllers to a wide range of motion, IoT and edge tasks in an industrial environment, depending on customer needs.

Festo Virtual Assistant – AI-supported support across all phases

Festo is constantly developing the topic of “seamless connectivity”. The Festo Virtual Assistant is an example of this. The AI-powered application helps with design, installation, assembly, maintenance, or specifications. It integrates several of Festo’s data sources and provides concrete answers via ChatGPT technology.

In its first version, the Virtual Assistant is linked to the documentation of the Festo Support Portal, including manuals, data sheets and operating manuals. This integration allows the AI-driven chatbot to conduct technical support conversations in a human-like manner and interactively reference relevant information.

Festo is a global player and an independent family-owned company with headquarters in Esslingen am Neckar, Germany. Festo has set standards in industrial automation technology and technical education ever since its establishment, thereby making a contribution to sustainable development of the environment, the economy and society. The company supplies pneumatic and electrical automation technology to 300,000 customers of factory and process automation in over 35 industries. Digitalization, AI and the LifeTech sector with medical technology and laboratory automation are becoming increasingly important. The products and services are available in 176 countries.

With about 20,600 employees in over 250 branch offices in around 60 countries worldwide, Festo achieved a turnover of around €3.45 billion in 2024. More than 8% of this turnover is invested in research and development. In this learning company, 1.5 % of turnover is invested in basic and further training. Festo Didactic SE is a leading provider of technical education and training and offers its customers worldwide comprehensive digital and physical learning solutions in the industrial environment.

More Information

Related Story

Festo Canada Celebrating 50 Years of Helping Make Canada an Automation Nation

The year was 1975. Newly created Festo Canada joined an industrial eco-system feeling the stirrings of accelerating technological change, a transformation that would become known as Industry 3.0. PLCs, articulated robots, computer numerical control systems were beginning to proliferate. The first US patent for Ethernet was filed that year. (That was also the year Festo launched the world’s first standard pneumatic cylinder series).

So much more was to follow, leading up to Industry 4.0 as we are experiencing today – digitalization, the Industrial internet of Things, cloud computing – and beyond, as industry begins widespread adoption of artificial intelligence and machine learning, with a growing emphasis on sustainability.