Tariffs – Can You Look Within?

February 12, 2025

OPINION By Swathi Mohan, Founder of Leanacle Inc.

I was standing backstage at a company townhall, running through my talking points, but my mind was elsewhere. Will they be engaged? Will they relate to what I’m saying? What if I lose them halfway through?

The more I thought about it, the more anxious I became. I was so caught up in how the audience might react that by the time I stepped up to speak, I didn’t deliver the message I had originally planned. Instead of leading with confidence, I second-guessed myself. Instead of owning the moment, I let my worries take over.

And when the night shift meeting came around, I knew I had missed an opportunity.

But something clicked after that. I realized I had been focusing entirely on things outside of my control—their reactions, their engagement, their interest. But what I could have focused on was how I showed up, how clearly I conveyed my message, and how much value I delivered.

So, for the next shift meeting, I changed my approach. This time, I focused on what was within my control. I walked in with clarity. I spoke with purpose. And instead of worrying about how they would receive my message, I focused on simply delivering it with conviction.

And you know what? That made all the difference.

What Does This Have to Do with Tariffs? Everything.

Right now, Canadian automotive SMEs are staring down a huge challenge—rising U.S. export tariffs that could drive up costs and disrupt supply chains. And it’s easy to feel the same way I did before that townhall: uncertain, powerless, waiting to see what happens next.

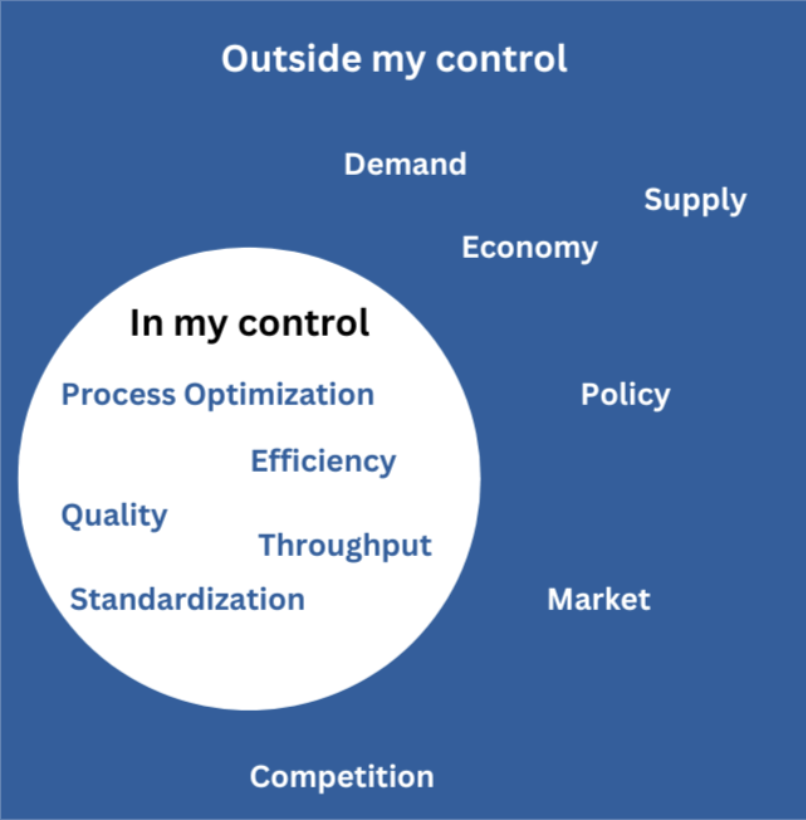

But here’s the thing: You can’t control the tariffs. You can’t control government policies. You can’t control how the market reacts.

What you CAN control is how you respond.

- You can tighten your operations and eliminate inefficiencies.

- You can optimize your supply chain and find cost-saving opportunities.

- You can make smart, proactive decisions now that strengthen your business for the long run.

This isn’t about waiting for policies to change. It’s about making changes within your own walls that put you in control.

Take Toyota West Virginia’s Cam Chatter Checker, for example. Instead of investing in expensive new equipment, they built a simple, low-cost tool that reduced defects and saved money—a perfect example of how small, internal improvements can create big financial wins.

The businesses that survive uncertainty are the ones that focus inward—on efficiency, adaptability, and continuous improvement.

So the question is: What’s under your control today?

Preparing for Uncertainty: How Ready Are You to Face Tariffs?

As manufacturers set their 2025 strategies, is your business prepared to navigate these challenges?

Recent articles highlight how companies across the industry are adapting to economic shifts. The key takeaway? The most successful businesses aren’t waiting for external solutions; they’re strengthening their operations now.

Tariff Readiness Checklist

To assess where your business stands, use this Tariff Readiness Checklist. It will help you:

✔ Identify inefficiencies in your current processes

✔ Evaluate supply chain risks and opportunities

✔ Explore cost-saving measures and revenue-enhancing strategies

Building a Resilient 2025 Strategy

By learning from industry leaders and adopting a mindset of continuous improvement, SMEs can navigate uncertainty with confidence—ensuring growth and profitability in 2025 and beyond.

Let’s start there.

👉 Check out the Tariff Readiness Checklist to see exactly where you can take action now.

About the Author

Swathi Mohan is the founder of Leanacle, helping SME automotive manufacturers boost revenue by increasing operational efficiency.

More Information

Related Story

From Suits to Steel-Toes: Why Shop Floor Harmony Builds Manufacturing Gold

OPINION By Swathi Mohan, Founder of Leanacle Inc.

What if there was a way to provide a voice to the employees as well as generate a return on investment?

Now are talking.

There is a proven, practical way to achieve all of this—not only bridging the gap but also driving operational efficiency by uncovering hidden opportunities on the shop floor with the insights from those adding value every day. Discover why engagement on the shop floor is instrumental for running a successful manufacturing business.